Liquid supply device and liquid ejecting apparatus

A technology of liquid supply and injection device, which is applied in printing and other directions, and can solve the problems that the position of the choke valve is not disclosed, and there is no choke valve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

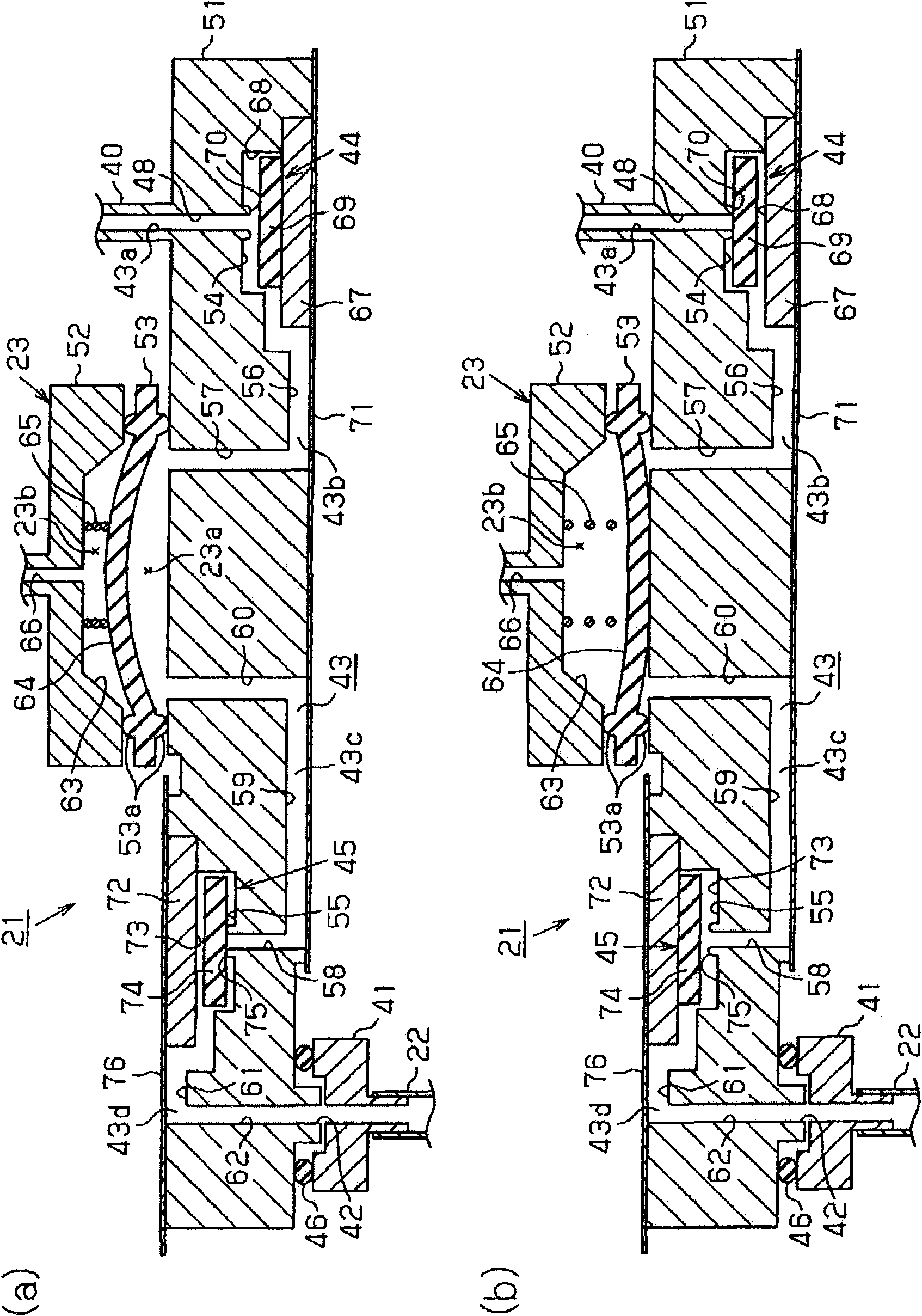

[0204] As the choke valve, a non-spring-biased differential pressure valve is used, but a spring-biased differential pressure valve may also be used. In addition, the choke valve may be constituted by a solenoid valve. Even with these configurations, as long as the slug valve is provided on the recording head and the slug cleaning can be completed by one discharge drive of the pump 23, effective slug cleaning can be performed without wasting ink.

Deformed example 2

[0206] The buffer chamber 32 can also be discarded. As long as sufficient ink can be supplied even during suction driving of the pump 23 , there is no problem even if there is no buffer chamber 32 . In addition, in the structure without the buffer chamber 32, it is easier to set the ink outflow amount Vink to be less than the ink ejection amount Ppump that can be supplied by one ejection drive of the pump 23, and one ejection amount of the pump 23 can be obtained. Actuation can end the effect of the barrier wash.

Deformed example 3

[0208] The pump is not limited to a diaphragm pump, and other pulsation type pumps capable of suction drive and discharge drive may be used. For example, bellows type pumps (ripple type pumps) and piston type pumps may also be used. Even in this case, by satisfying the condition of the ink outflow amount Vink<the ink outflow amount Vpump, the gas barrier cleaning can be completed by one discharge drive of the pump, and effective gas barrier cleaning can be performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com