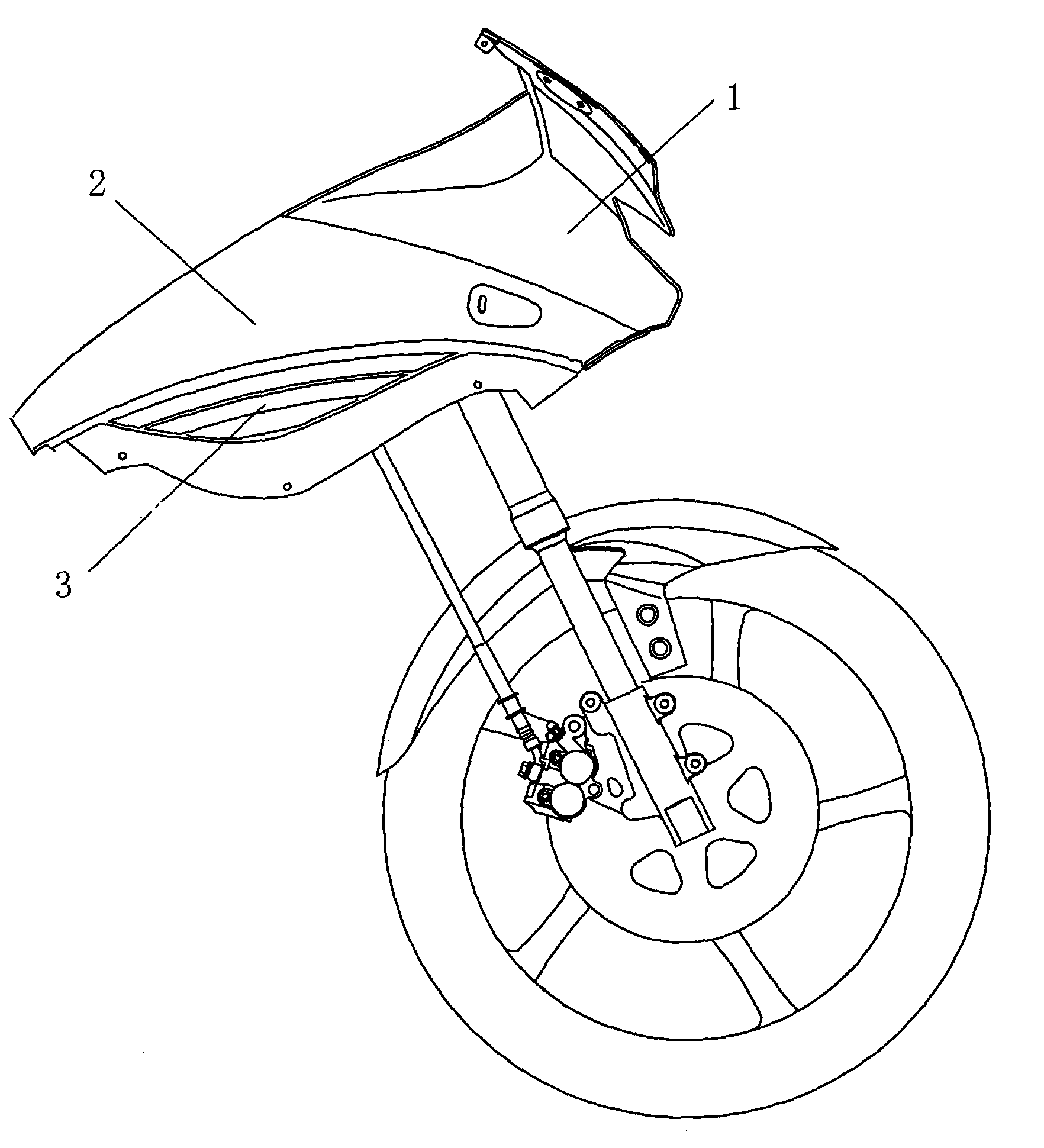

Connecting structure of motorcycle covering pieces and front body covering piece assembly

A technology for connecting structures and covering parts, which is applied in bicycle accessories, weather guards, transportation and packaging, etc. It can solve the problems of long-term rust, assembly difficulties, and screw heads affecting visual appearance, etc. The effect of natural surface transition and easy appearance modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

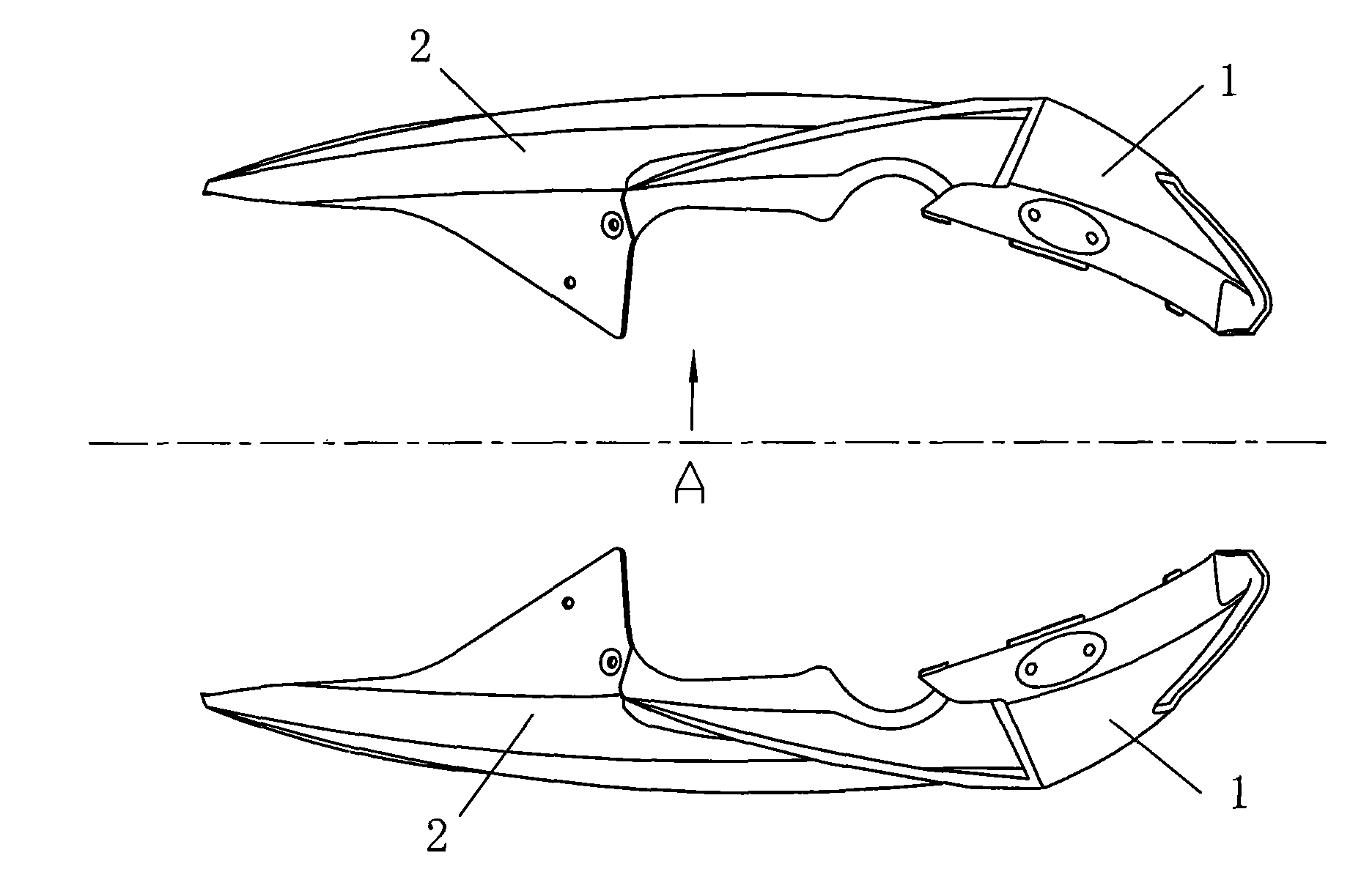

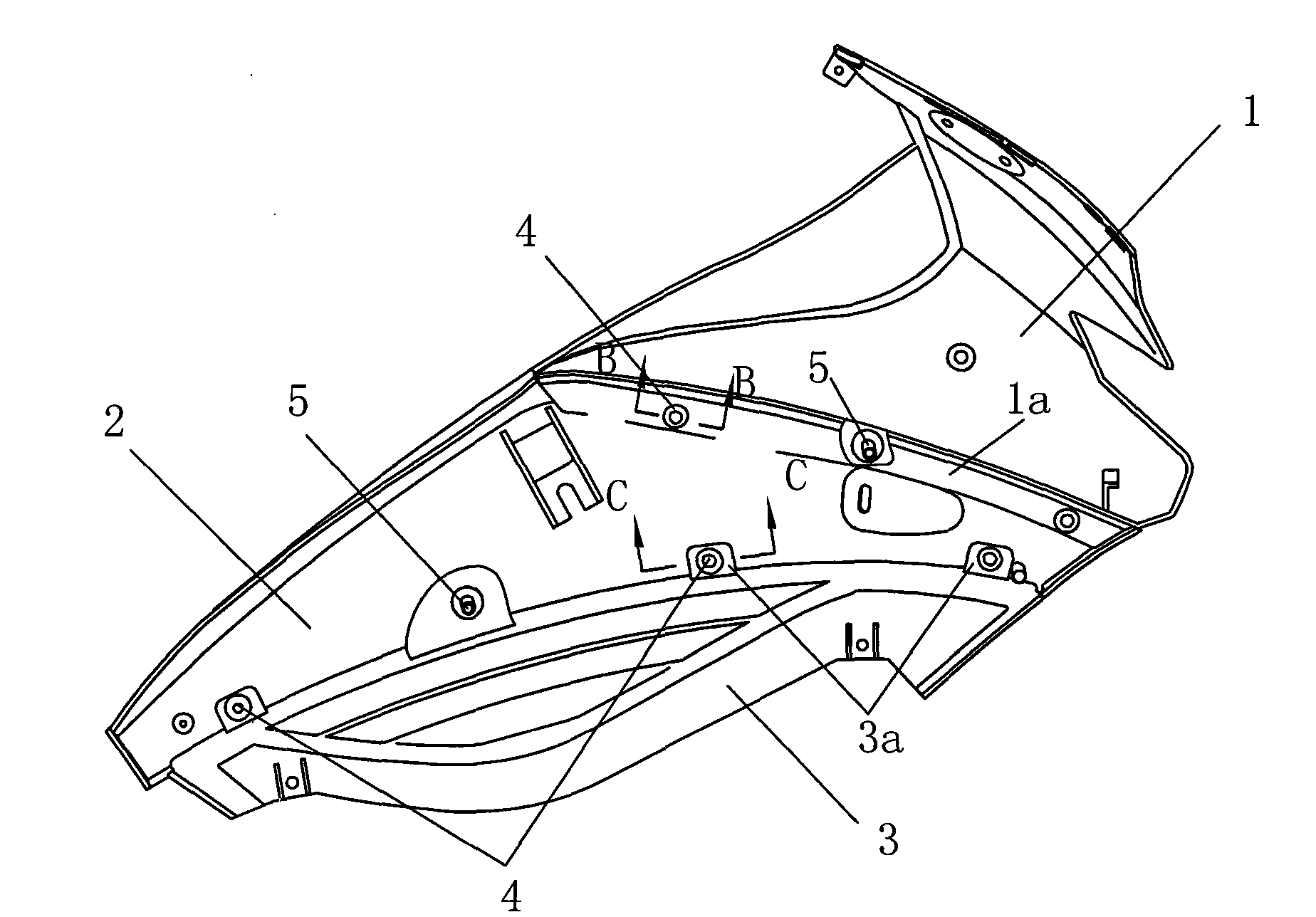

[0022] Such as image 3 , Figure 4 As shown, the present invention provides a connection structure of a motorcycle cover. Two adjacent covers, the front cover guard 1 and the side cover trim 2, are bent outwards at the lower edge of the front cover guard 1. There is a strip-shaped overlapping edge 1a, and on the plane where the overlapping edge 1a deviates from the outer surface of the front mask guard plate 1, three bosses 4 are provided. The bosses 4 are hollow bosses with a longitudinal section of "∏" shape, The lower end of the inner hole of the boss passes through the lap edge 1a, and the top surface of the boss 4 has a central hole 4a, which is used as a via hole for the self-tapping screw 6; On the side, there are three cylinders 5 corresponding to the inner holes of the hollow boss 4. The center of the top of the cylinder 5 is provided with a blind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com