Plastic uptake package

A technology of blister packaging and side parts, applied in the field of blister packaging, can solve problems such as trouble, finger injury, lining paper falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

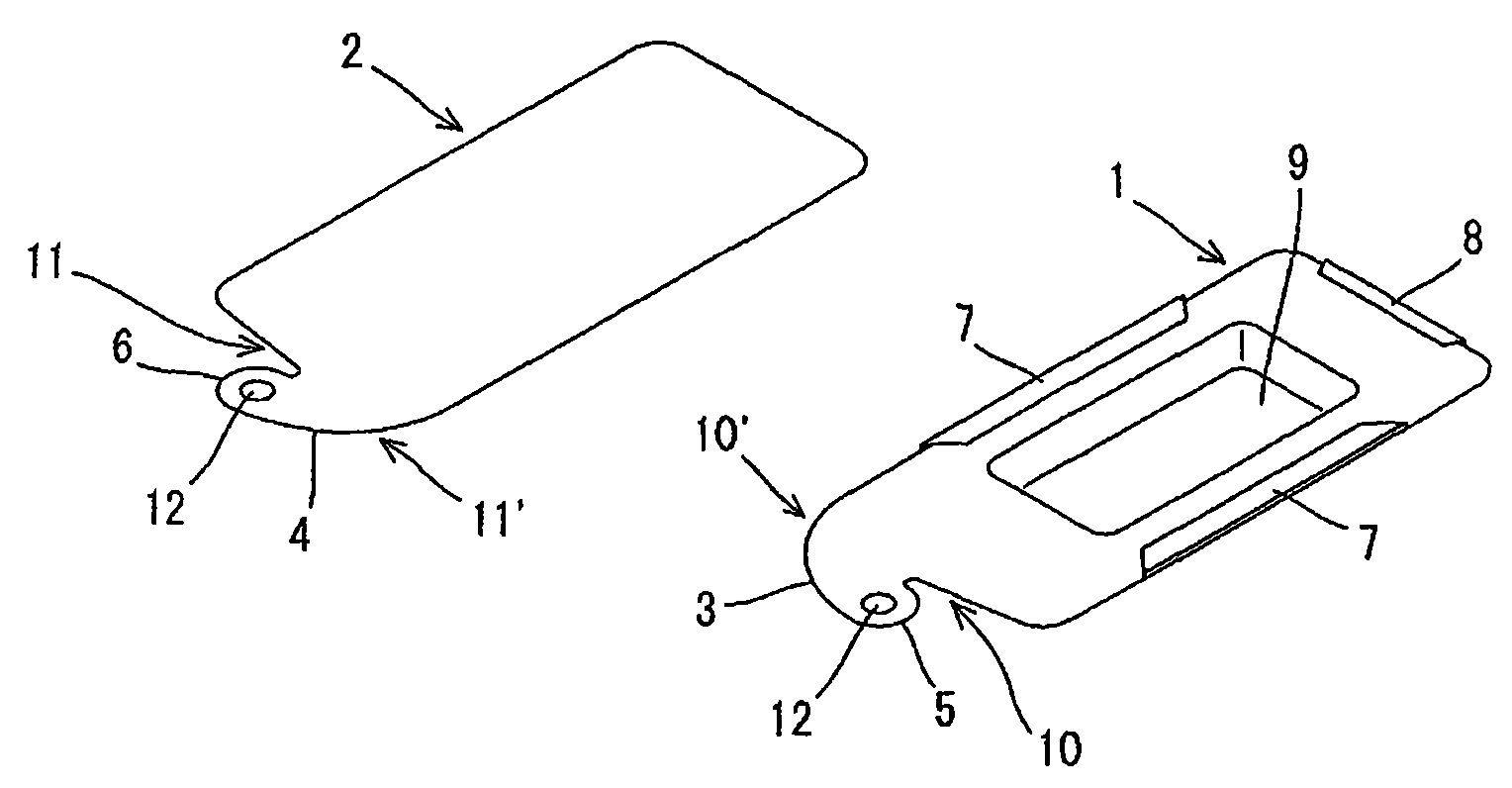

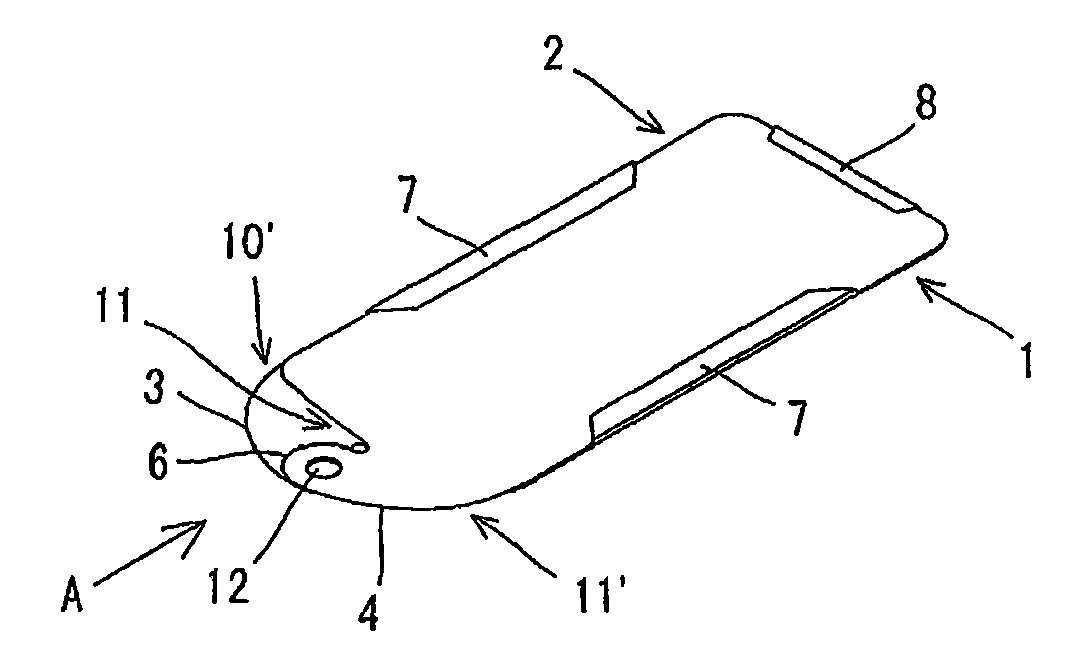

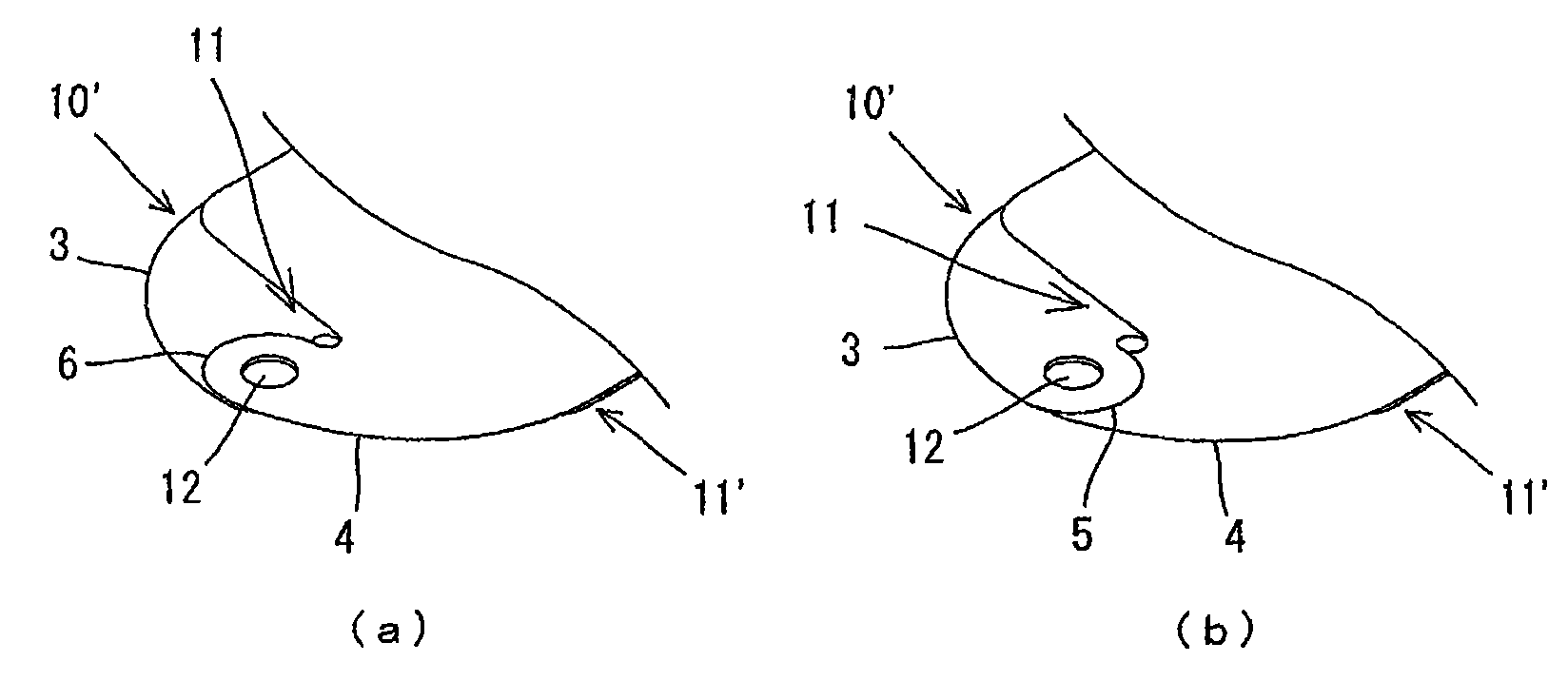

[0035] Next, specific examples of the blister package of the present invention will be described with reference to the drawings.

[0036] Figure 1 to Figure 7 The shown blister package is composed of the receiving side part, namely the blister cover 1, and the closing side part, namely the backing paper 2, and the backing paper 2 is inserted into the flap provided on the edge of the blister cover 1 to hold the backing paper 2 ( The so-called slide blister (Slide blister) used in Flap)7.

[0037] As a first embodiment ( Figure 1 to Figure 4 ), the blister cover 1 is formed by vacuum forming of a flexible transparent synthetic resin sheet material such as polyethylene terephthalate.

[0038] In addition, the backing paper 2 generally uses paper materials such as coated paper, but a sheet material made of synthetic resin can also be used like the above-mentioned blister cover, and as long as it has flexibility, raw materials other than synthetic resin can also be used.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com