Nano-diamond thermal grease

A technology of nano-diamond and nano-diamond powder, which is applied in the direction of heat exchange materials, chemical instruments and methods, and can solve the problems of affecting the thermal conductivity of heat dissipation paste, poor thermal conductivity of heat dissipation paste, and poor thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

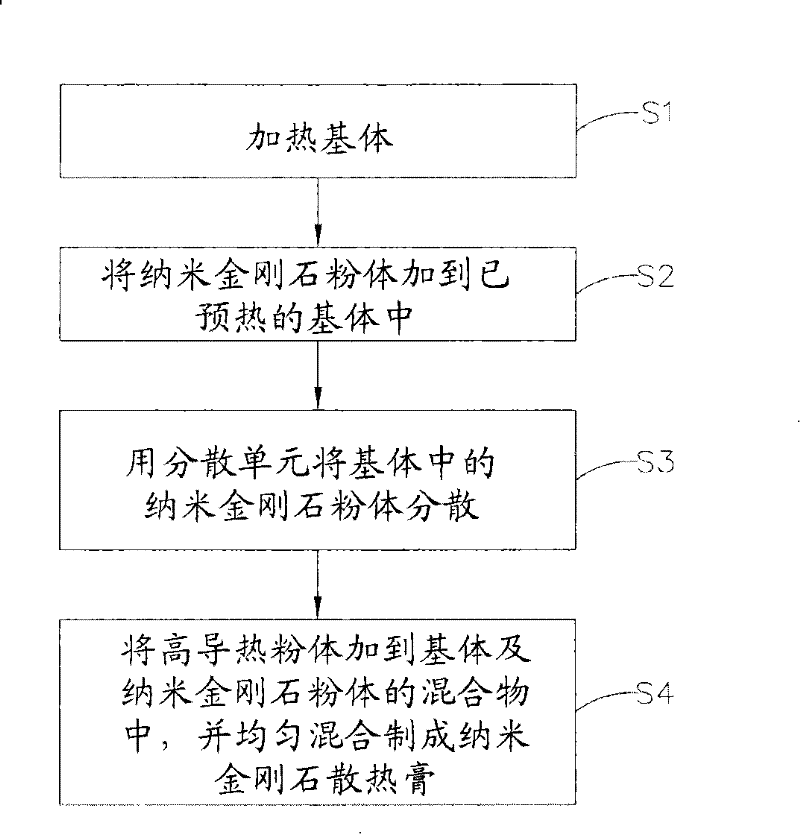

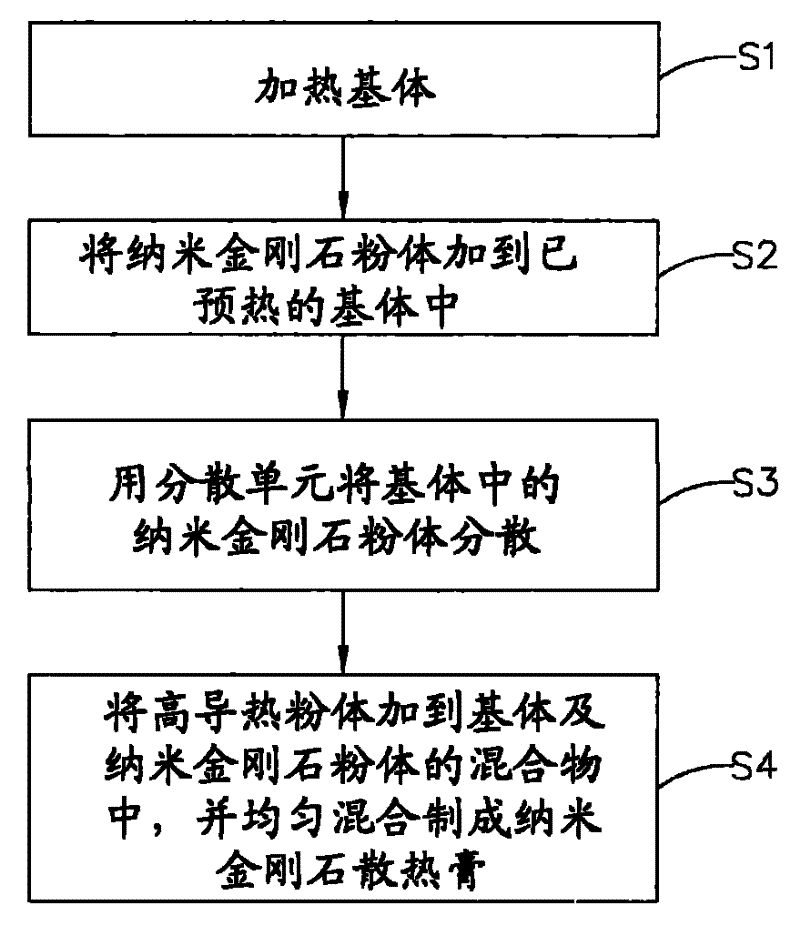

Method used

Image

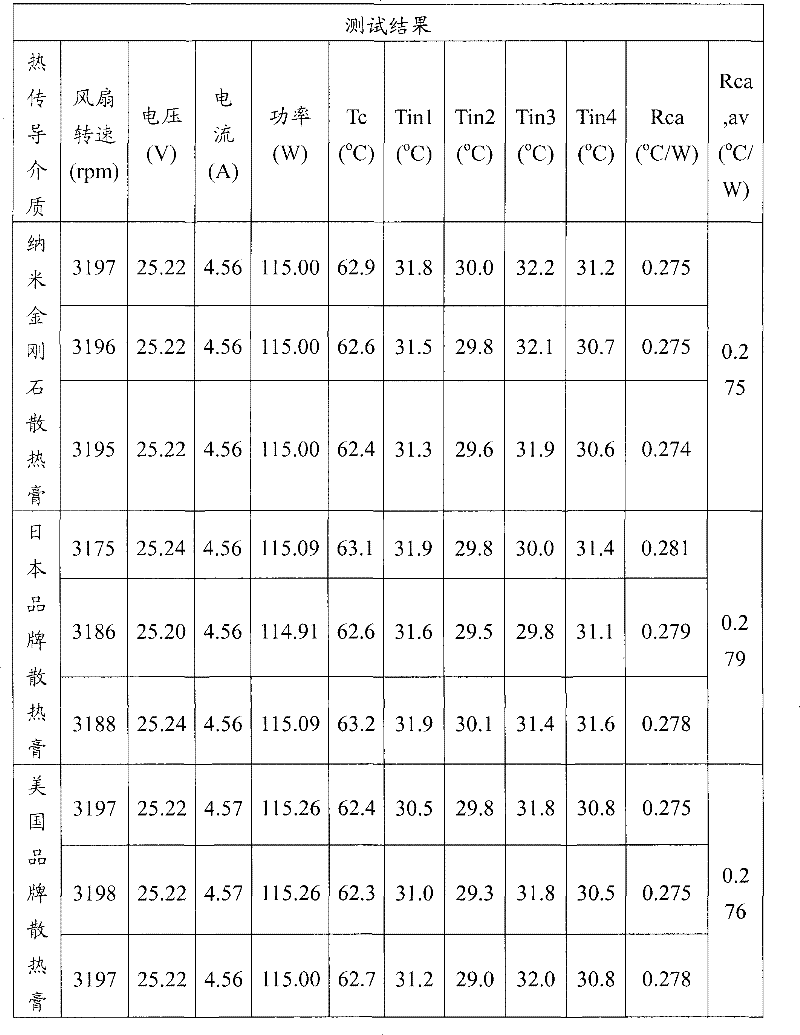

Examples

Embodiment Construction

[0031] The invention provides a nano-diamond heat dissipation paste. The nano-diamond heat dissipation paste comprises nano-diamond powder, high thermal conductivity powder and a matrix. The volume percentage of the nano-diamond powder is 5-30%, the volume percentage of the high thermal conductivity powder is 40-90%, and the volume percentage of the matrix is 5-30%. Among them, the nano-diamond powder and the high thermal conductivity powder are evenly dispersed in the matrix to become a nano-diamond thermal paste with high thermal conductivity.

[0032] The high thermal conductivity powder may include a first high thermal conductivity powder with a larger particle diameter and a second high thermal conductivity powder with a smaller particle diameter. The first high thermal conductivity powder can be a powder with a diameter of 15-50 microns, the second high thermal conductivity powder can be a powder with a diameter of 1-10 microns, and the first high thermal conductivity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com