Self-lubricating vacuum pressure compound air pump

A vacuum pressure, self-lubricating technology, applied to pumps, pump components, rotary piston pumps, etc., can solve the problems of gas turbulence, unadjustable working plane, slow heat dissipation of compressed gas, etc., to facilitate adjustment and improve trouble-free work Time, the effect of improving product life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

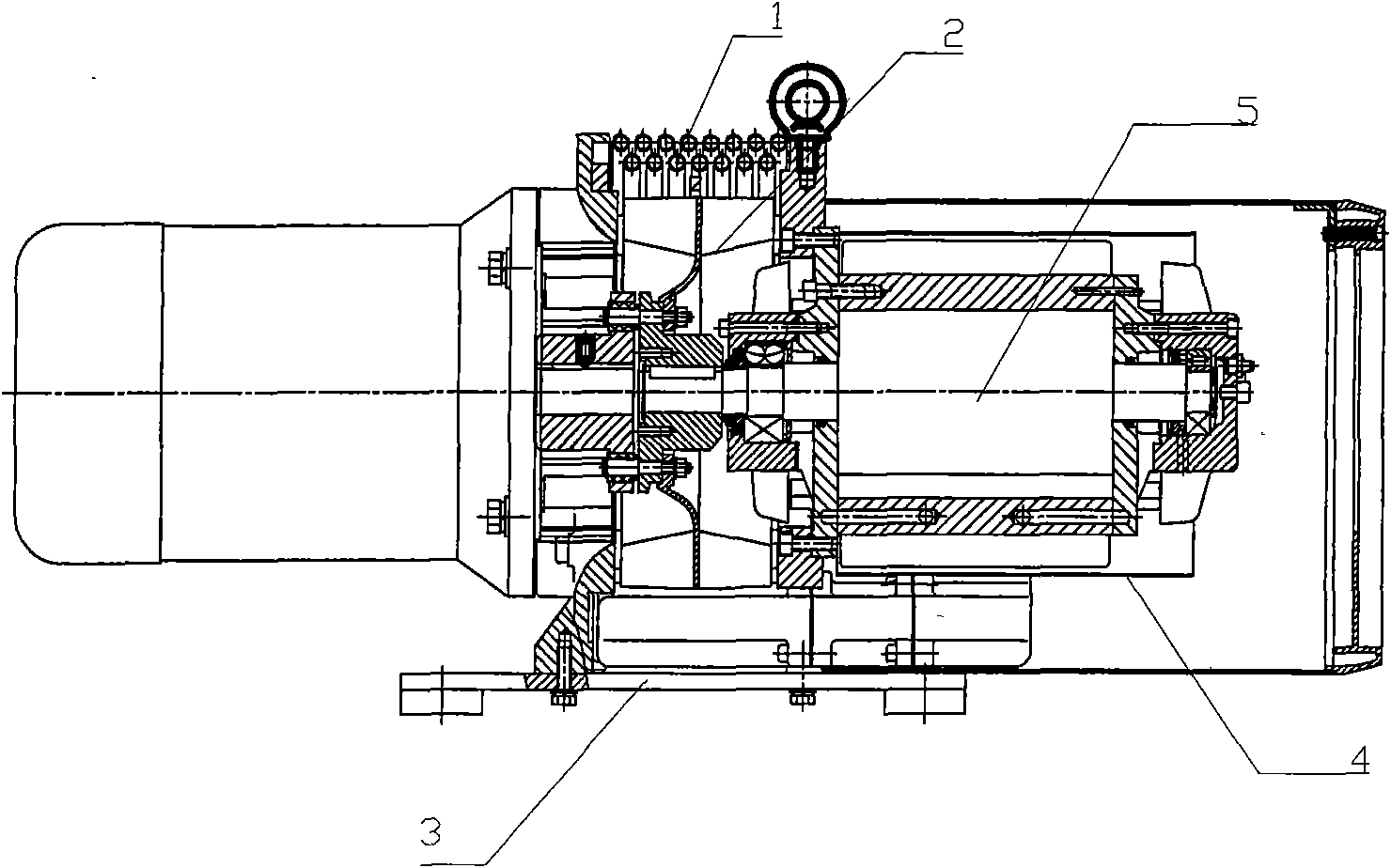

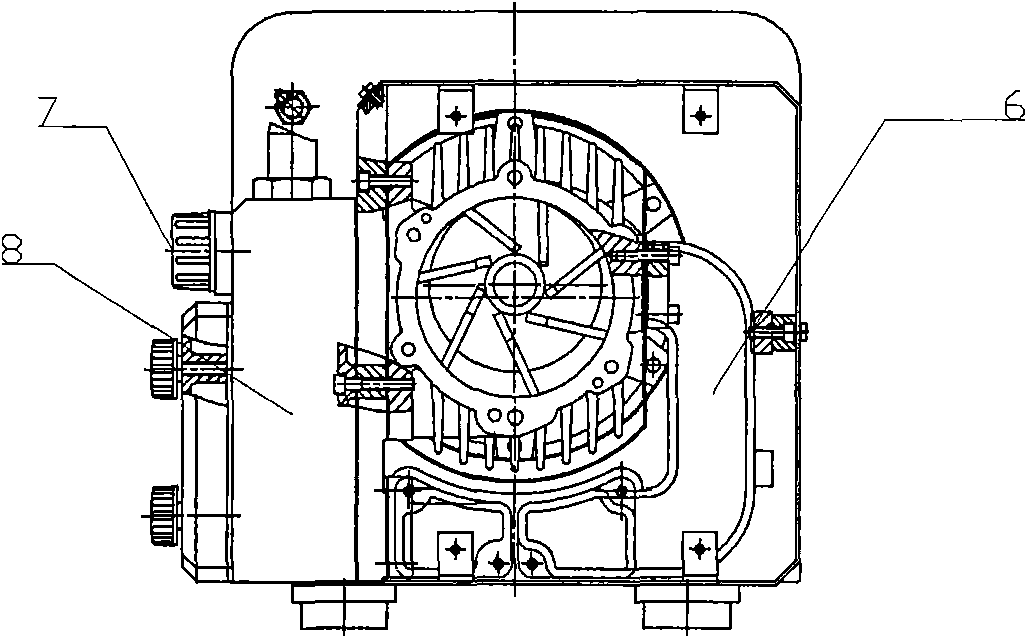

[0014] like figure 1 The one shown is connected with an exhaust elbow on the pump body, and the exhaust elbow is connected to one end of the recooling component. There is an air duct 9 on the top of the exhaust chamber 8, and the air duct 9 is connected to the cooling pipe 1. The cooling component It is installed outside the pump body and covered above the fan. There is a shroud 4 between the pump body and the outer cover, and a bracket is fixed at the bottom of the air pump.

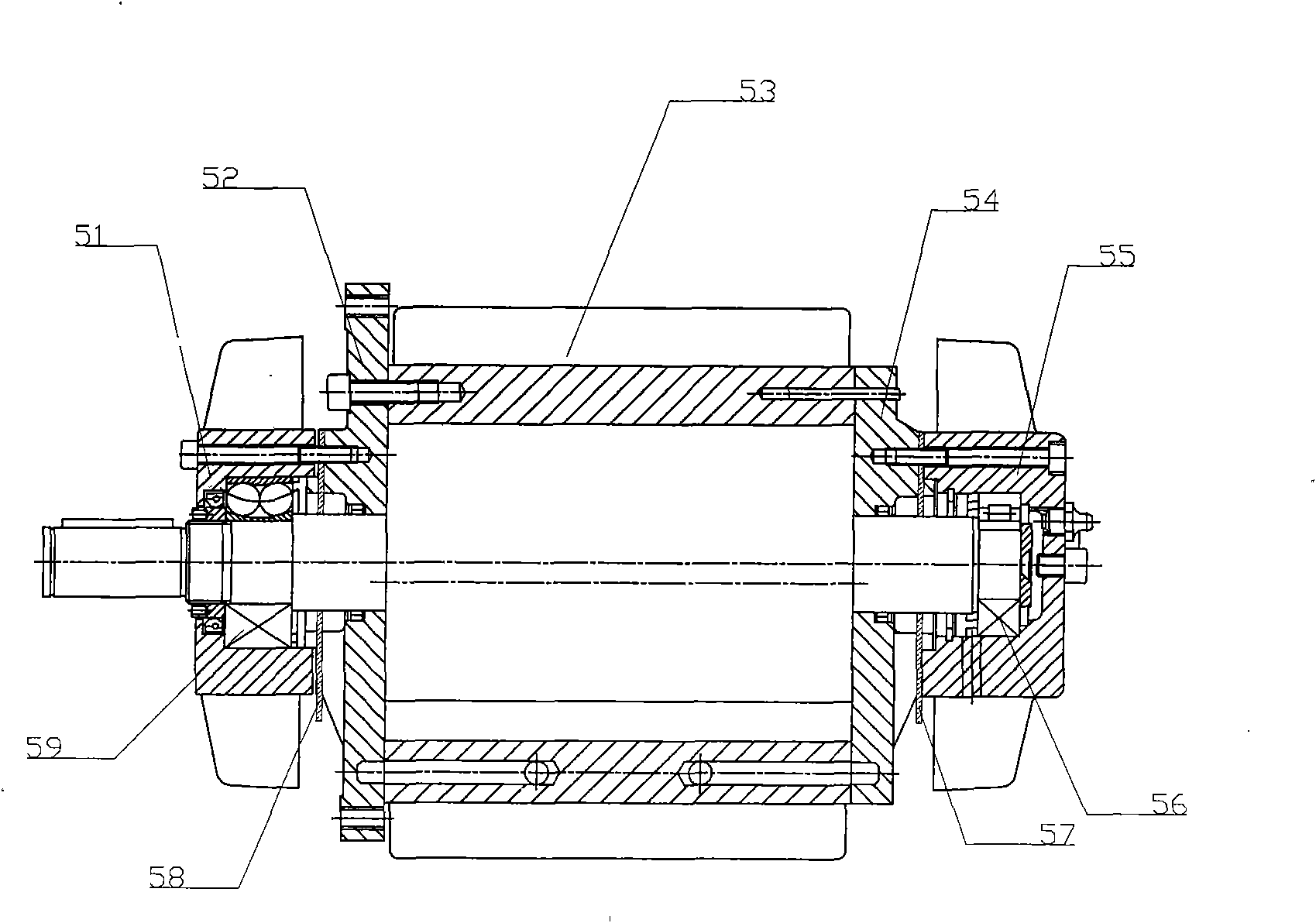

[0015] like image 3 The structure of the pump body 5 shown is that the front end is provided with a front end cover 52, and the rear end of the pump body 7 is provided with a rear end cover 54, and a front bearing seat 51 is installed on the boss of the front end cover 52, which is fixedly connected by screws, and the front bearing Front bearing 59 is installed in the seat 51, and rear bearing seat 55 is installed on the boss of rear end cover 54, and rear bearing 66 is installed in the rear bearing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com