Classification and group matching methods based on multi weighing machines

A weighing machine and weighing technology, applied in the directions of weighing indicating device, weighing, measuring device, etc., can solve the problems affecting the production efficiency of lead-acid battery pole plate group, low efficiency, slow pole piece assembly and grouping speed, etc. , to achieve the effect of improving the matching speed, increasing the matching speed and improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

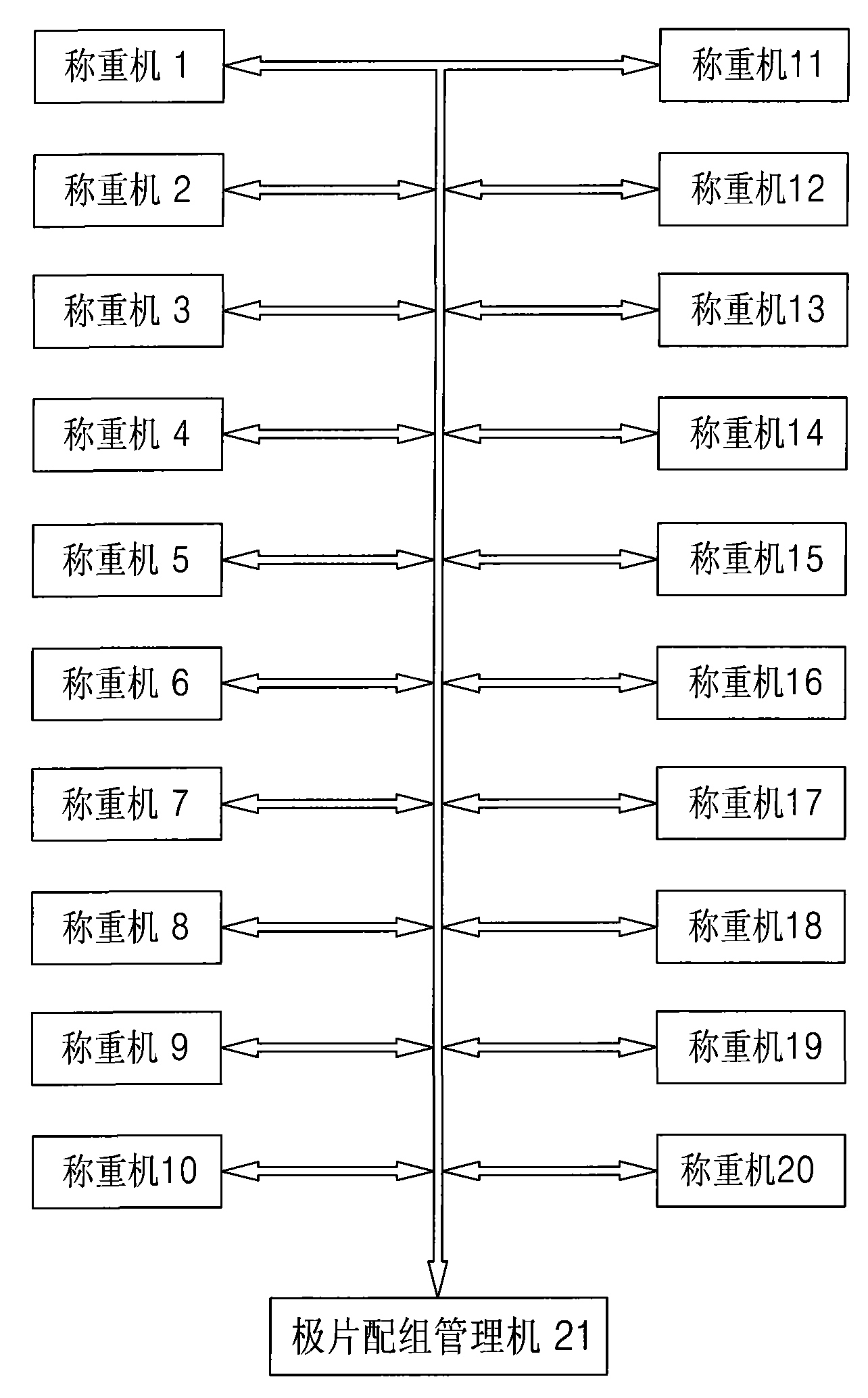

[0010] based on figure 1 The weighing and grouping system composed of 20 weighing machines 1-20 and the pole piece group management machine 21 shown in the figure classifies a single pole piece. The steps are: take no more than 20 pole pieces at a time Distributed to different weighing machines for weighing, that is: each weighing machine only weighs one pole piece at a time, and each weighing machine transmits its own weighing results to the pole piece through RS-485 communication In the configuration management machine 21, the pole piece group management machine 21 automatically classifies according to the preset weight range of a single pole piece, and informs the classification result through voice prompts.

Embodiment 2

[0012] based on figure 1 The weighing and matching system consisting of 20 weighing machines 1 to 20 and pole piece matching management machine 21 shown in the figure is to match 3+2 pole plate groups. The steps are: take no more than 10 plates each time. A first pole piece group composed of 3 pole pieces and no more than 10 second pole piece groups composed of 2 pole pieces are distributed to different weighing machines for weighing, namely: each weighing machine Only one first pole piece group or the second pole piece group is weighed at a time, and each weighing machine transmits the result obtained by itself to the pole piece matching management machine 21 through the RS-485 communication mode, and the pole piece matching The group management machine 21 compares the weight value of any first pole piece group that has not been matched with the weight of any second pole piece group that has not been matched according to the weight range to be met by the preset 3+2 pole plate...

Embodiment 3

[0014] based on figure 1 The weighing and matching system consisting of 20 weighing machines 1 to 20 and the pole piece matching management machine 21 is shown, and the 3+3 pole plate groups are matched. The steps are: take no more than 20 plates each time. A pole piece group composed of 3 pole pieces is distributed to different weighing machines for weighing, that is, each weighing machine only weighs one pole piece group at a time, and each weighing machine passes RS-485 The communication method transmits the respective weighing results to the pole piece matching management machine 21, and the pole piece matching management machine 21, according to the weight range to be met by the preset 3+3 pole plate sets, divides any two pole pieces that are not matched into groups. Add up the weight values of the electrode groups, and if the obtained weight sum meets the set weight range of 3+3 electrode groups, the matching group is successful, and the matching result will be informe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com