Composite insulator by injection molding once

A technology for injection molding composite and insulators, applied in the direction of suspension/strain insulators, etc., can solve problems such as water seepage, insulator breakage, mandrel hydrolysis, etc., and achieve the effect of overcoming creepage, improving sealing effect, and improving connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

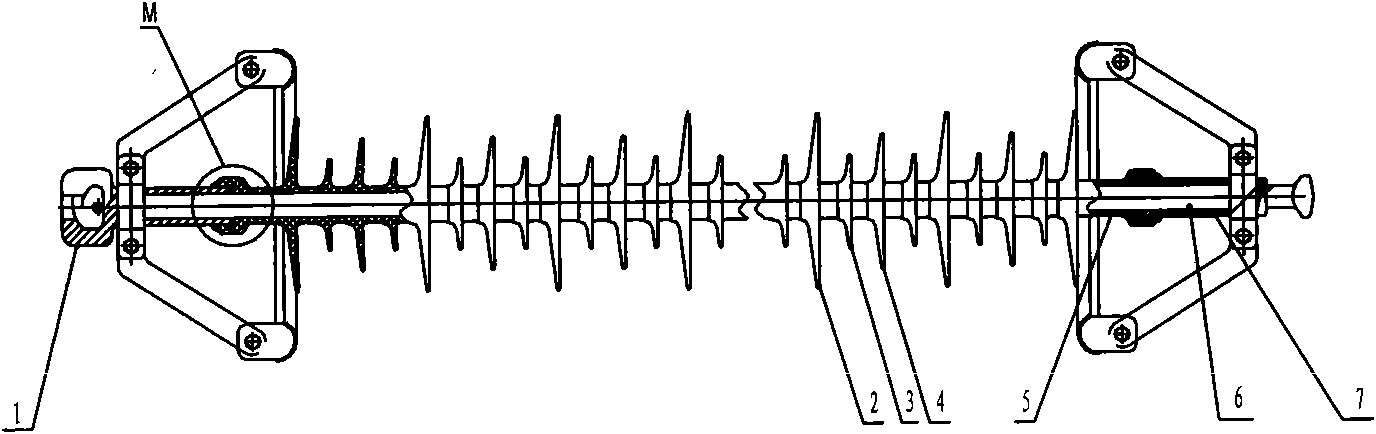

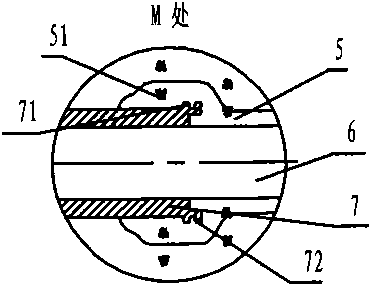

[0012] The invention is like figure 1 , 2 As shown, it includes a core rod 6, a fitting 1 with a tube-shaped joint 7, an umbrella skirt insulator, and a sheath 5 provided at both ends of the umbrella skirt insulator. The sheath 5 is located on the surface of the core rod 6 and is fixed to the core rod 6. , Its two ends are respectively fixedly connected to the nozzles of the fittings 1 with tubular joints 7 at both ends. The fittings 1 and the tubular joints 7 are provided with a step circle 71 facing the nozzle of the umbrella insulator, and the sheaths 5 at both ends of the umbrella insulator The step circle 71 of the nozzle of the fitting is covered by a coating layer 51 and water-tightly connected. At least one circle of grooves 72 is provided on the outer turning surface of the step circle 71, and the coating layer 51 covers the circle of grooves 72 to form a lip type sealing structure.

[0013] Umbrella insulators include large umbrella skirt 2, middle umbrella skirt 4, sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com