Automatic production line apparatus for automatically immersing chamber, immersing paint, vacuumizing and drying

An automatic assembly line, fully automatic technology, applied in the direction of electrical components, pretreatment surface, inductance/transformer/magnet manufacturing, etc., can solve a lot of manpower and material resources, affect production, waste time and other problems, to increase production and save production time , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

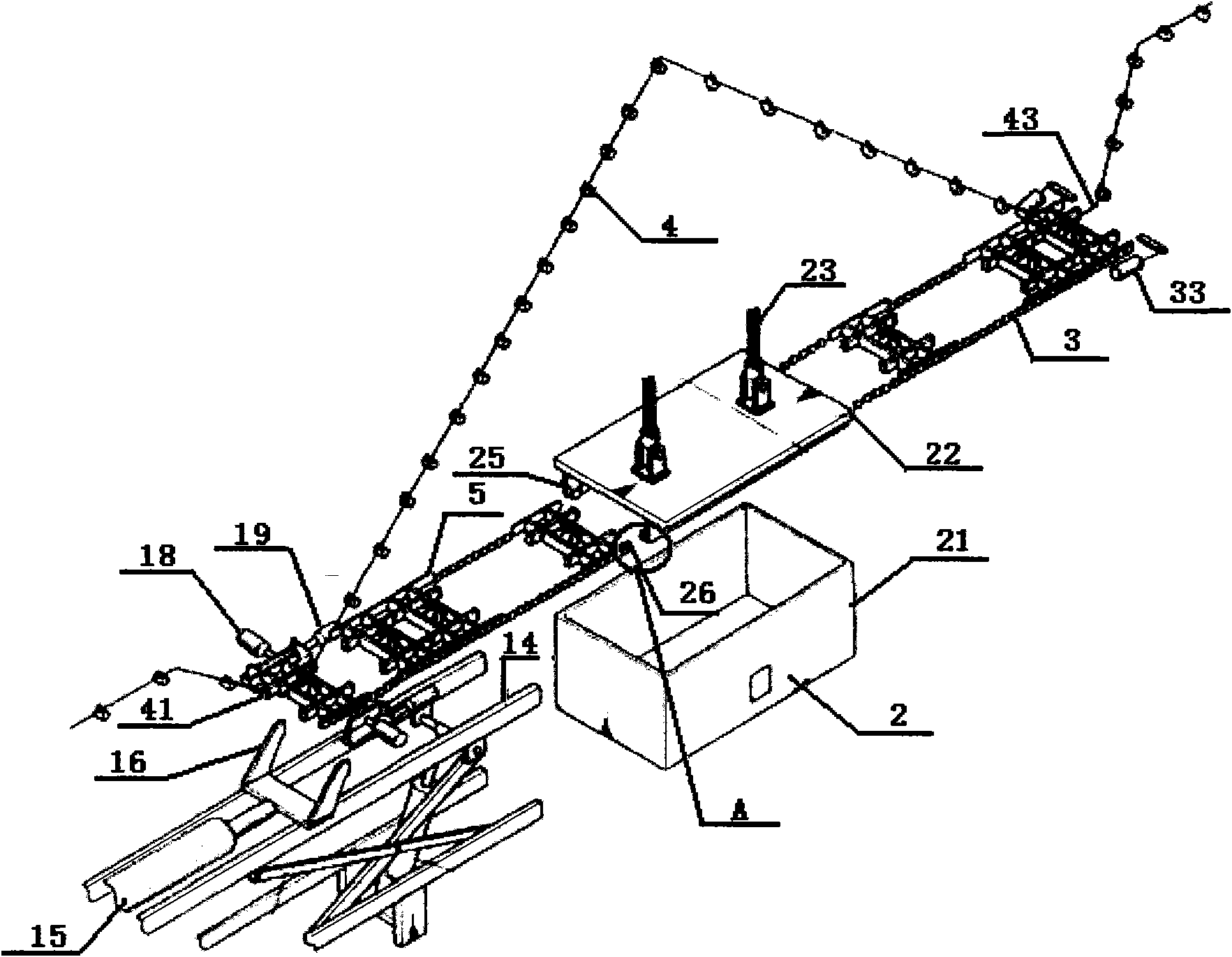

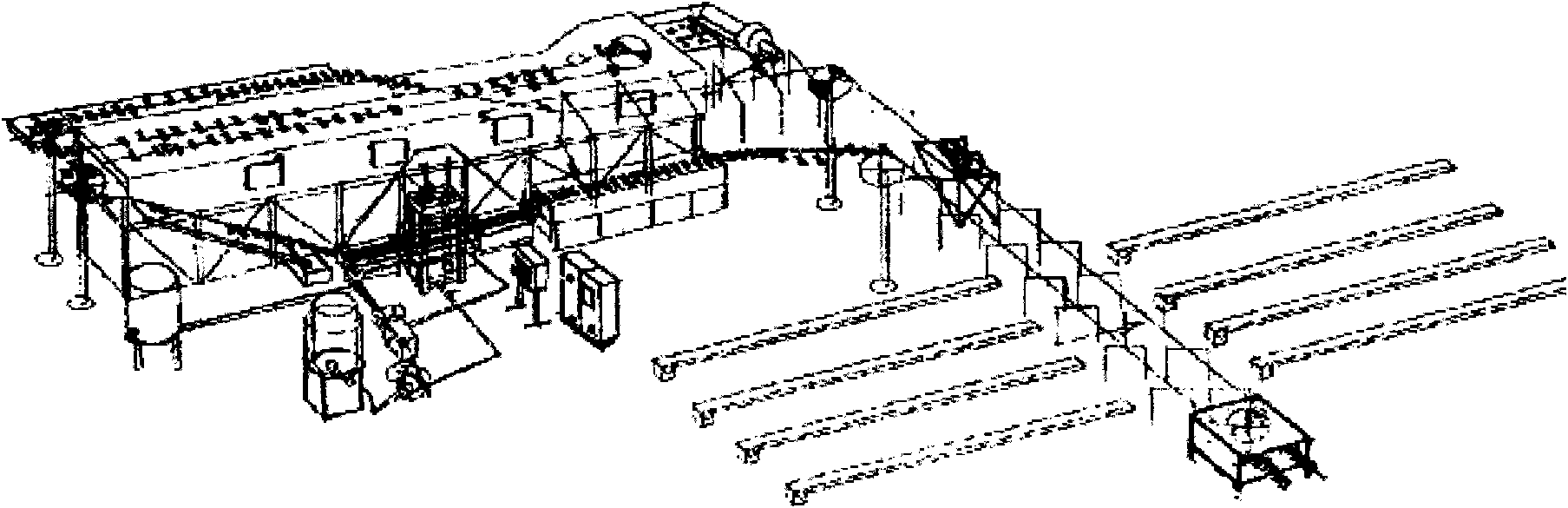

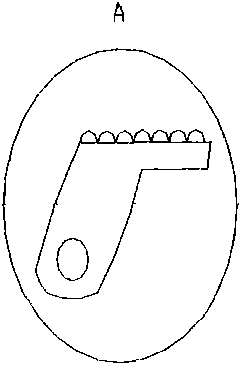

[0010] see figure 1 , the present embodiment adopts the following technical solutions: it is composed of liquid surface window 2, discharge port 3, chain 4, feed port 5, track 14, pushing gas steel 15, pushing frame 16, pushing frame lift-off and landing 16-1 , air clamping steel 18, air pulling steel 19, vacuum box 21, vacuum box cover 22, lifting screw 23, alignment wheel 25, guide wheel 26, air steel 33, hanger 41 and delivery chain 43; liquid surface window 2 is set outside the vacuum box 1, the vacuum box cover 22 is set between the discharge port 3 and the material inlet 5, the alignment wheel 25 is set on the inner side of the vacuum box cover 22, and the two lifting screw rods 23 are set in the vacuum Above the case cover 22 outsides, and parallel to each other, the hanger 41 is arranged on the top of the push frame 16, the entrained air steel 18 is arranged on the right side of the hanger 41, and the entrained air steel 19 is arranged in the entrained air steel 18 fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com