Method for the production of a filter element and filter element produced according to said method

A technology of filter elements and filter media, which can be used in household components, separation methods, filtration and separation, etc., and can solve problems such as time-consuming and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention will be explained below on the basis of an embodiment in which the formation of the laser-impermeable barrier layer is realized in that the welding foil described in detail below is used as an insert component in place prior to the welding process.

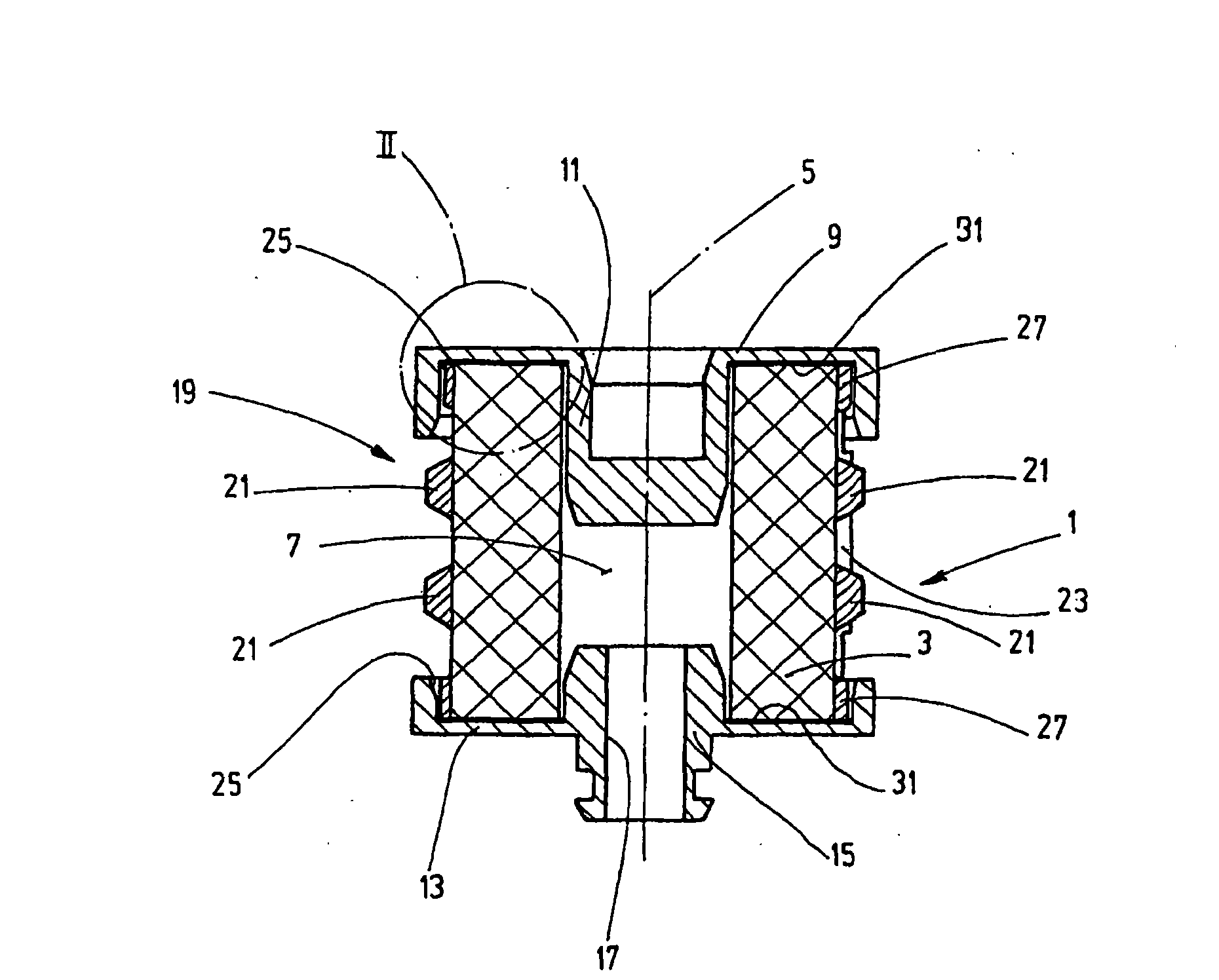

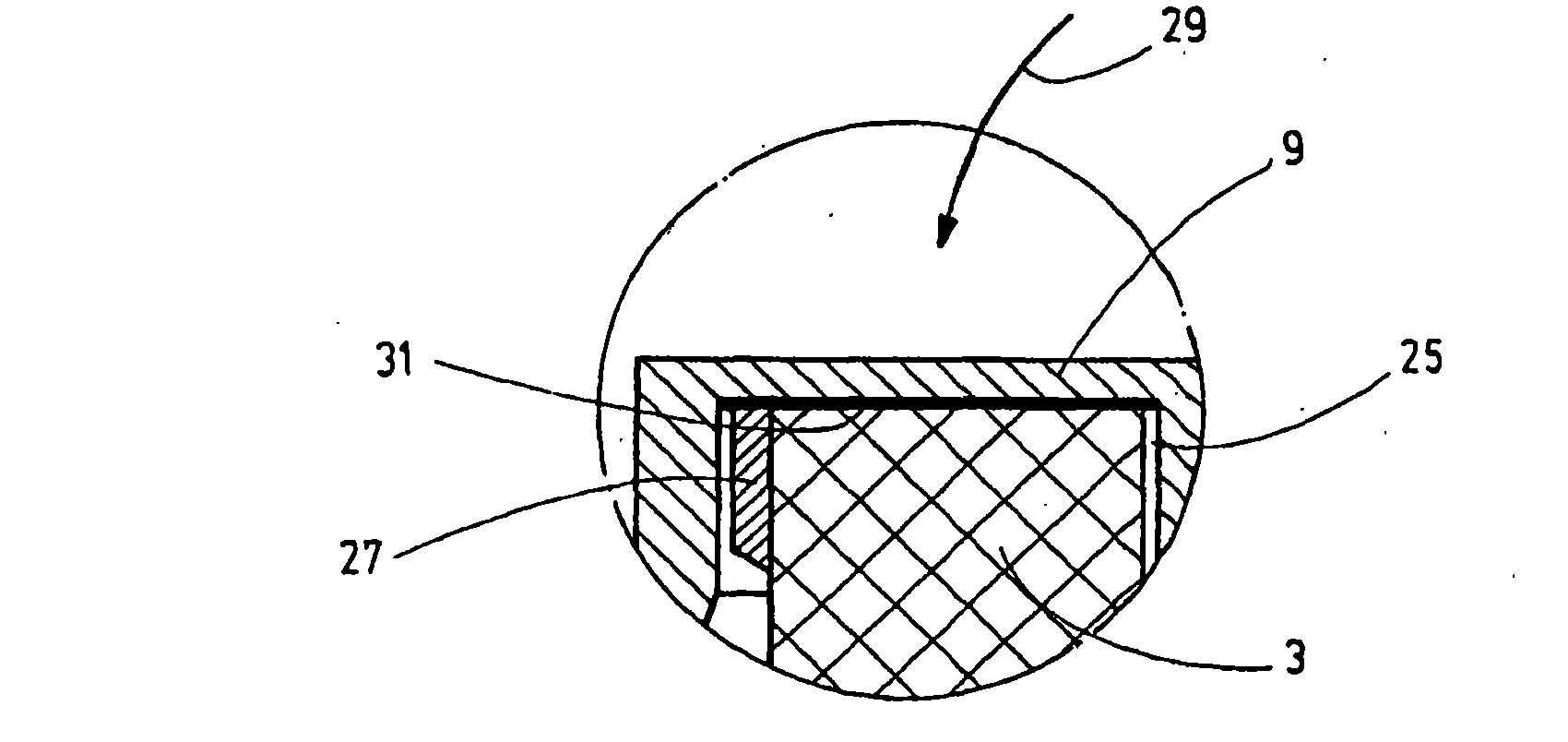

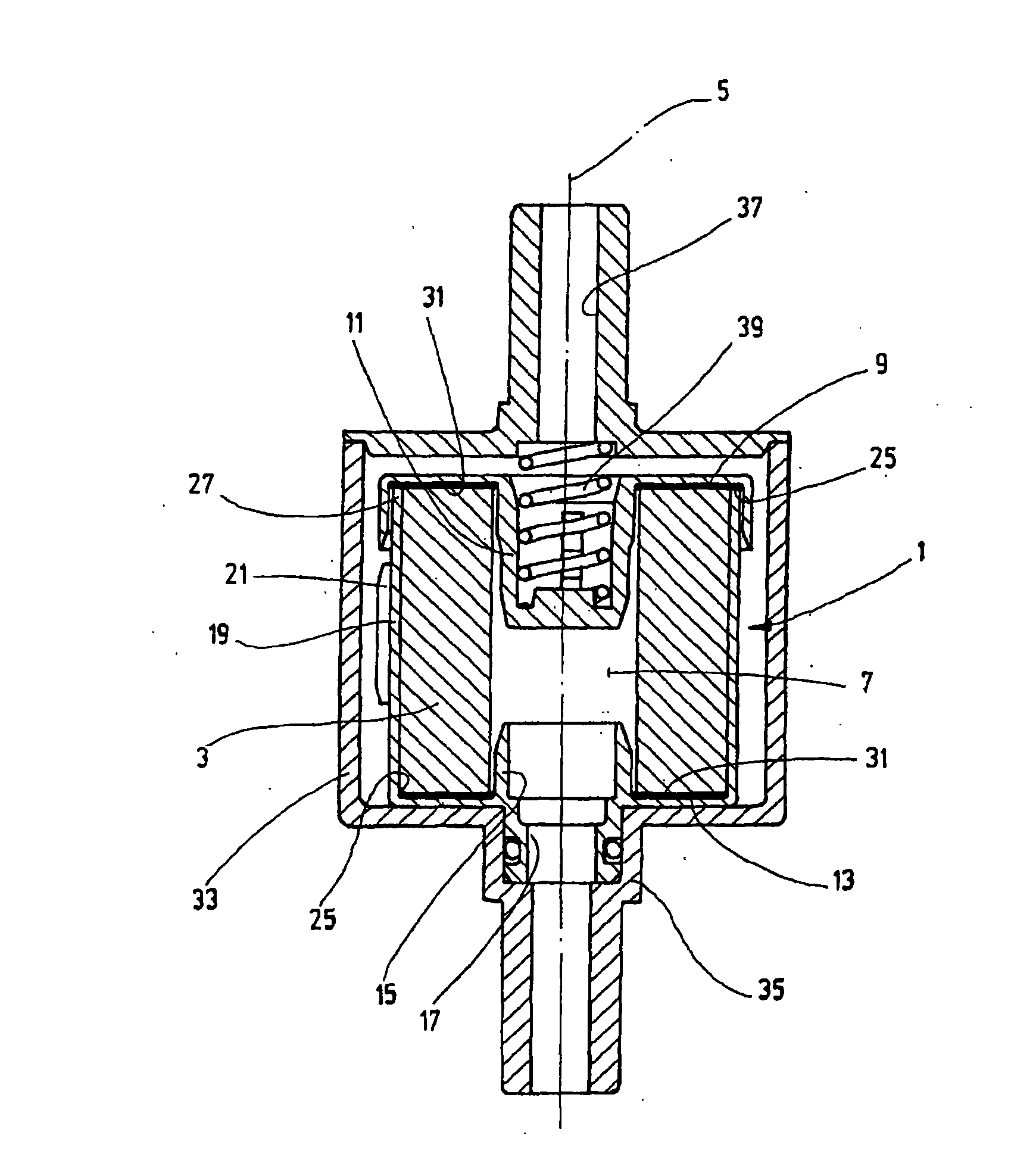

[0019] figure 1 with 2 A first exemplary embodiment of a filter element produced according to the method according to the invention is shown, which is designated as a whole by 1 . The main component is the filter medium, which is formed by a filter mat designed as an annular body 3 , which surrounds an inner filter cavity 7 in the shape of a hollow cylinder concentrically to the longitudinal axis 5 . The filter cavity is closed at one end by a cover-side end cap 9 which is formed in one piece from polyamide and has a central hollow pin 11 which is closed at the inner end and which runs along the edge of the ring body 3 The inner side extends into the filter cavity 7 . At the opposite, bottom-side end, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com