Automatic conveying and sorting system for sampling

A sorting system and automatic conveying technology, which is applied in the field of automation systems, can solve problems such as not being able to meet the rapid analysis of samples, and achieve the effect of high degree of automation and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

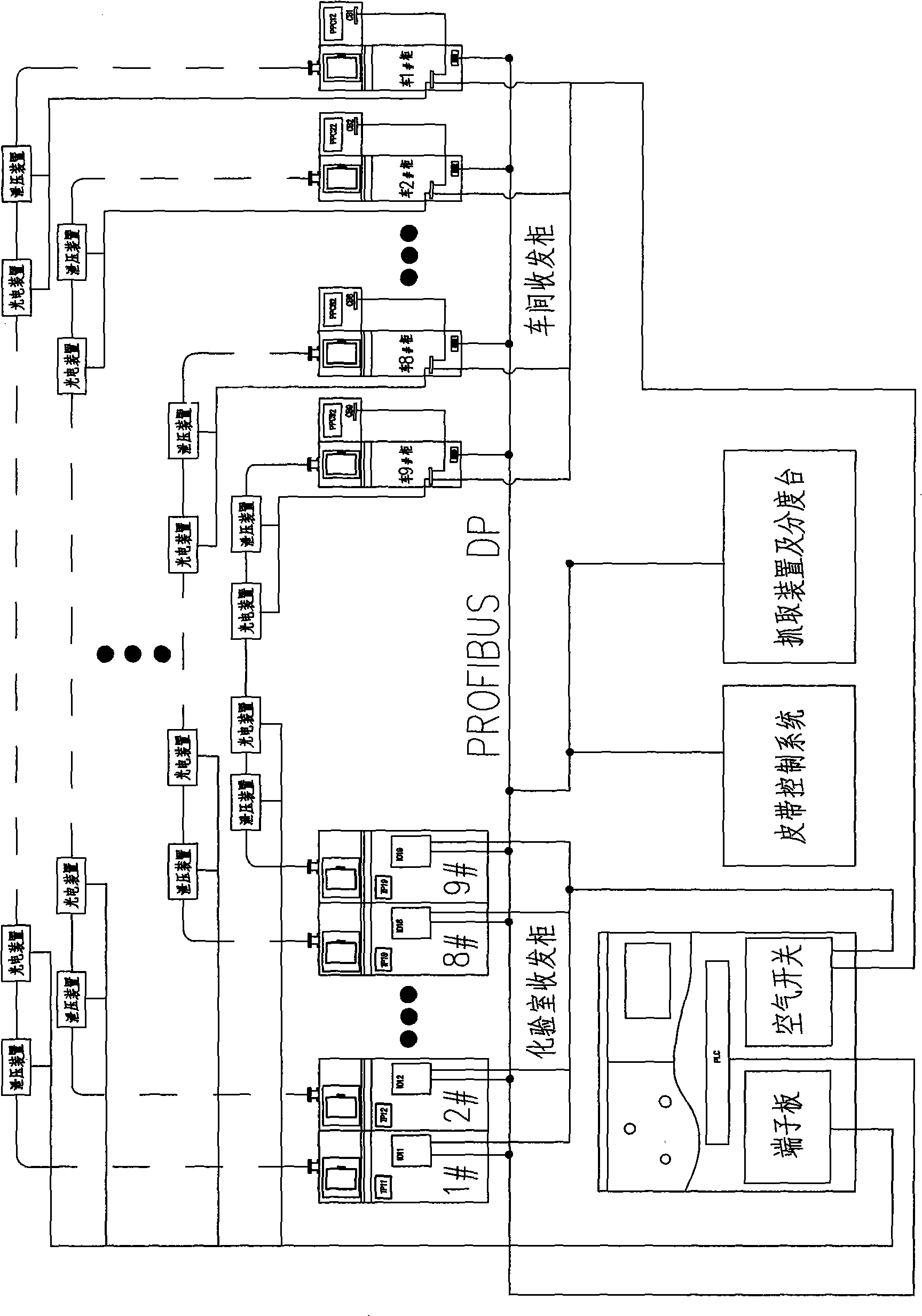

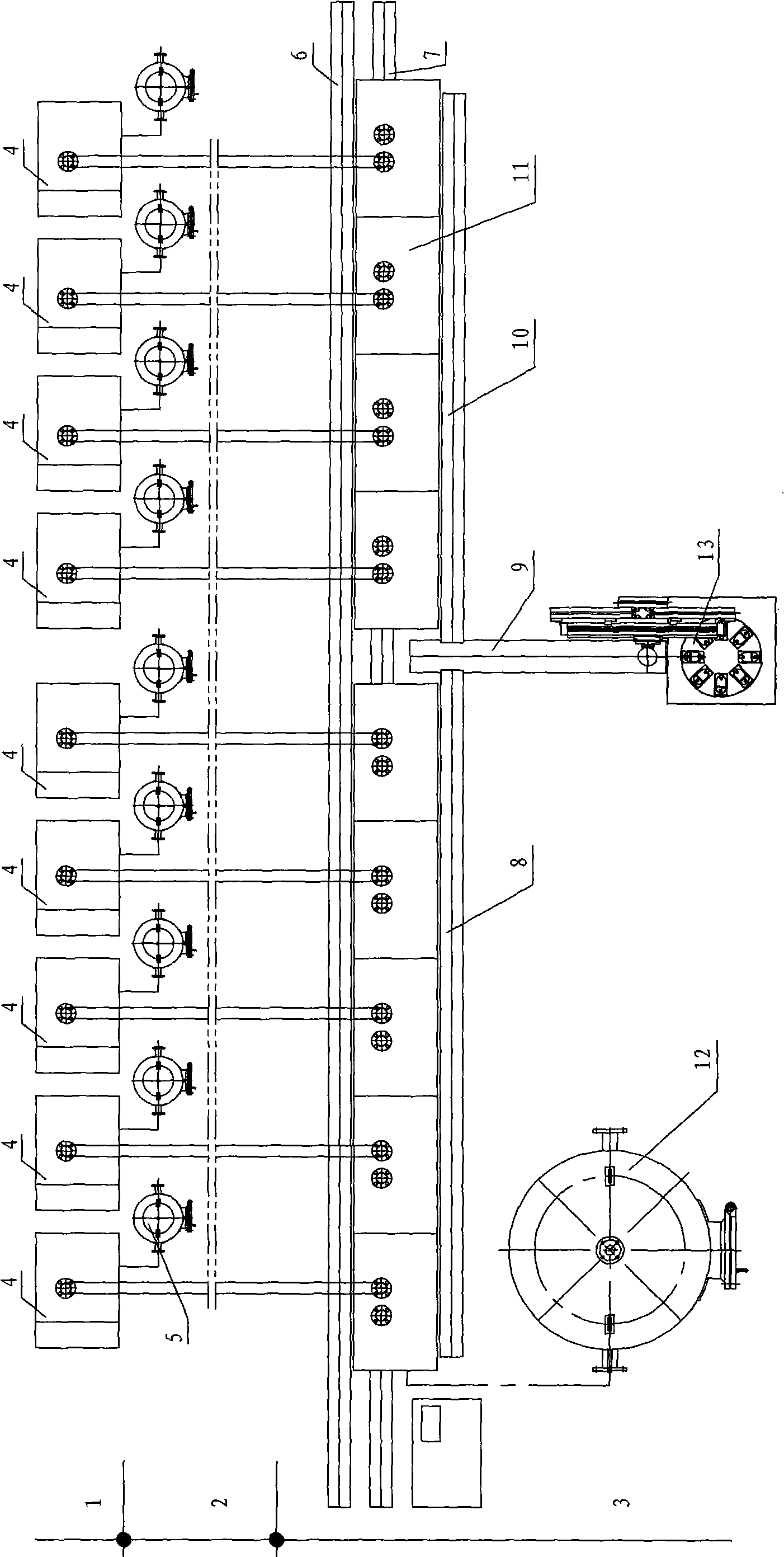

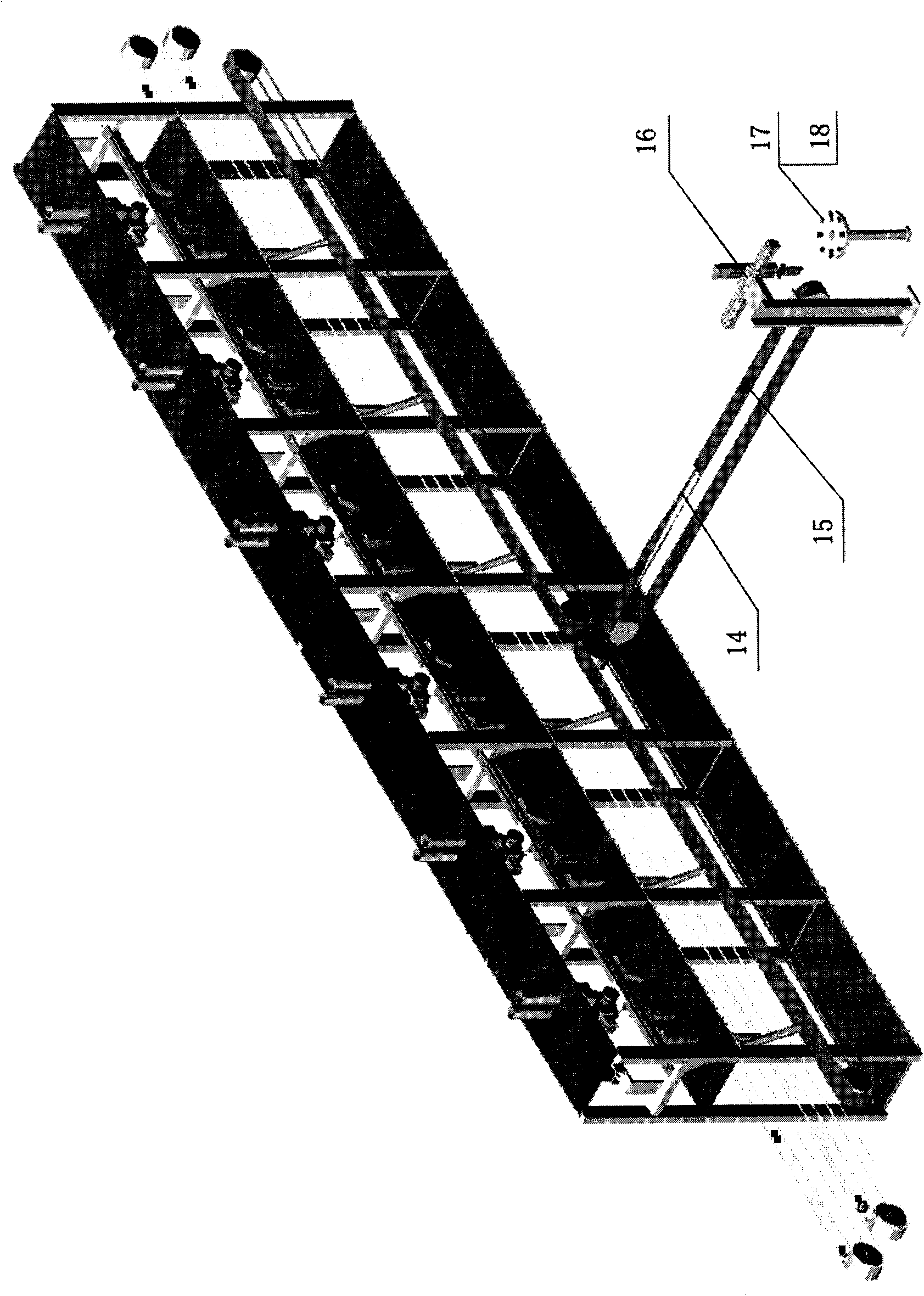

[0023] Such as Figure 1 ~ Figure 5 As shown, there are 9 receiving and dispatching cabinets in the workshop, which are numbered 1 to 9 in sequence, and the laboratory receiving and dispatching cabinet group is also composed of 9 receiving and dispatching cabinets, which are numbered sequentially. Each workshop receiving and dispatching cabinet and the corresponding laboratory terminal receiving and dispatching cabinet 11 are connected by a closed pipeline. A photoelectric device and a pressure relief device are arranged on the closed pipeline. The working process of each part is as follows:

[0024] 1) Wind transmission substation 1

[0025] The receiving and dispatching cabinet of the air transmission substation 1 is manually operated. The sample box is manually taken out and the sample box is opened and closed by the mechanical lid opener. Then the sample information is input, the sample and the ticket are put in, and the sample box is manually put into the substation. Statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com