Aqueous filler for woodware

A water-based, wood-based technology, applied in the direction of filling slurry, etc., can solve the problems of health damage to the operator, easy to cause fire, poor operability, etc., and achieve the effect of safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

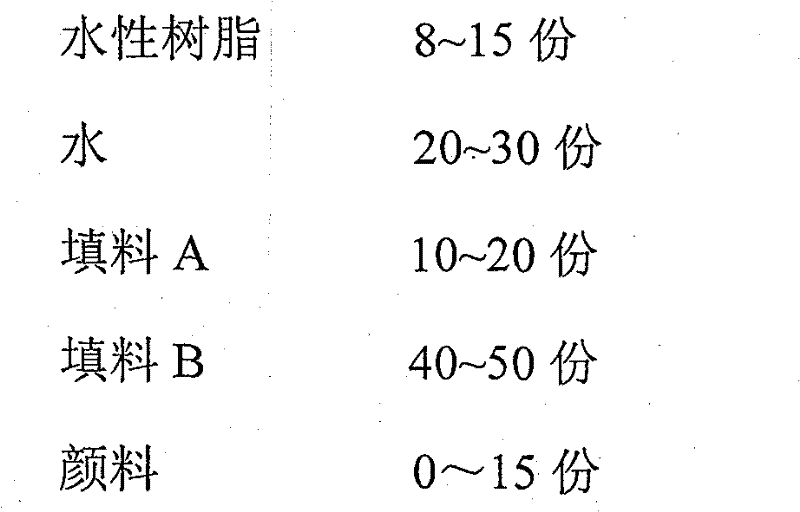

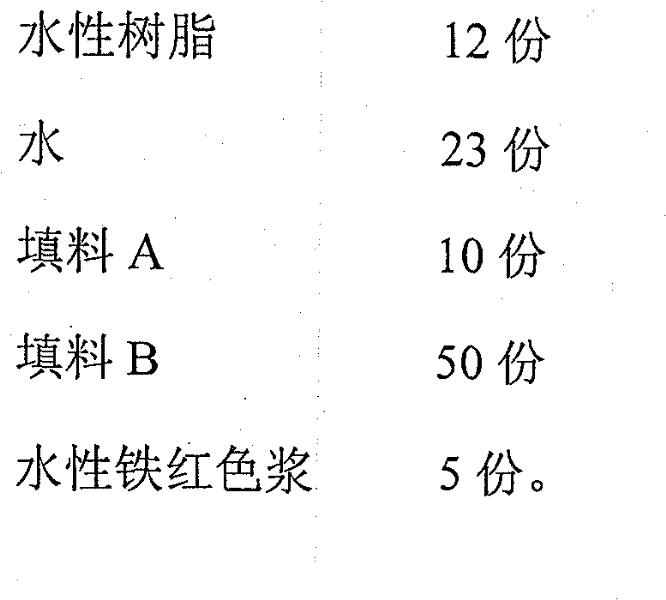

[0031] Components and parts by weight:

[0032] 12 parts of water-based resin, 28 parts of deionized water, 10 parts of 200 mesh quartz powder, 50 parts of 425 mesh mica powder, 5 parts of iron red paste

[0033] Put the water-based resin in first, add 80% of the total amount of deionized water, add quartz powder and mica powder under medium speed stirring, after the dispersion is uniform, then add iron red slurry, and finally add the remaining 20% of deionized water .

[0034] Wipe this product on ash or oak, sapele and other wood-grained boards, wipe it clean, after drying, then lightly sand the surface, spray the PU head bottom once, polish it after drying, spray PE primer once, and polish it after drying , Spray PU topcoat. The product can achieve a fully sealed effect. After drying for 48 hours, the adhesion is tested by the 100-grid method, and the adhesion is grade 1.

[0035] Spray the PU primer on the board wiped with filler, and polish it flat after drying, then...

Embodiment 2

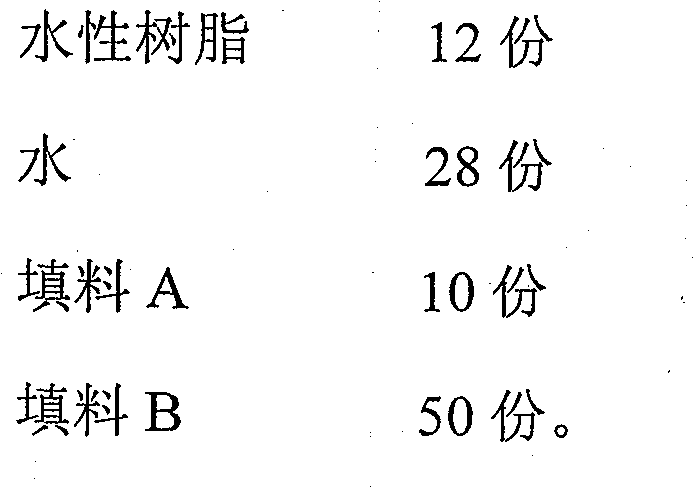

[0037] Components and parts by weight:

[0038] 15 parts of water-based resin, 20 parts of deionized water, 20 parts of 200 mesh quartz powder, 40 parts of 425 mesh mica powder. The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com