Dust collection device for printing and copying integrated machines

The technology of a dust collection device and an all-in-one machine is applied in the direction of dust removal, cleaning methods and appliances, chemical instruments and methods, etc., which can solve problems such as deterioration of the operating environment and impact on the personal health of the operator, and achieve a good operating environment and good dust removal effect , to ensure the effect of health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

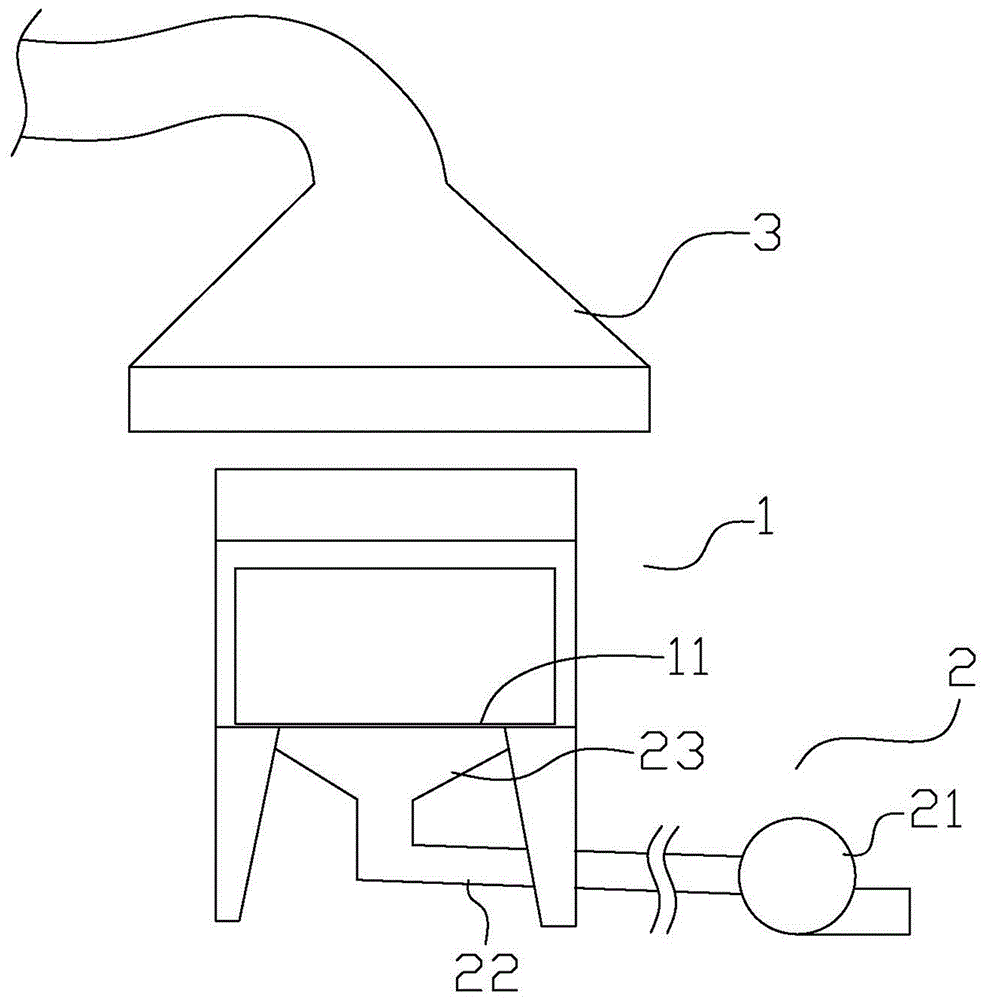

[0026] Example: Reference figure 1 and figure 2 , a dust collection device for printing and copying all-in-one machine, comprising:

[0027] A semi-enclosed console 1, one side of the console 1 has an opening for disassembly operation, feet are provided around the bottom, and a light source for lighting is provided inside;

[0028] A suction dust removal system 2 located at the lower part of the operating platform 1;

[0029] A protective cover 3 covering the top of the operating table 1, the protective cover 3 is externally connected to a vacuum pump to form a negative pressure suction environment above the operating table 1, and the inner diameter of the protective cover 3 gradually increases from top to bottom. Increased, the operating table 1 is completely placed within the range covered by its lower end contour.

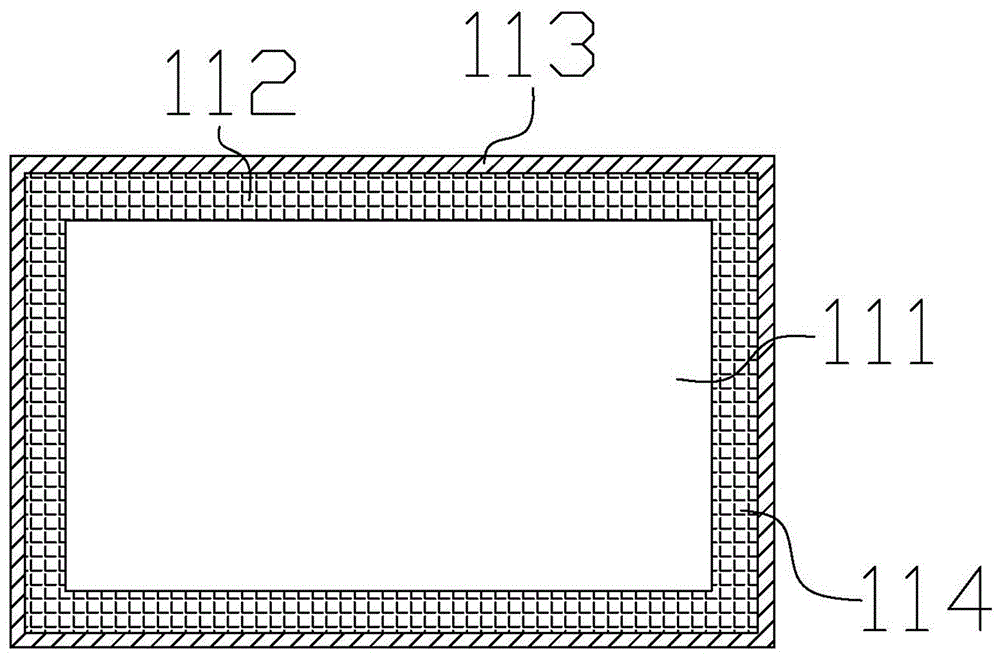

[0030] The console 1 includes an operating surface 11;

[0031] The operation surface 11 is composed of a placement portion 111, a wrapping 113 surrounding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com