High-performance environment-friendly water-based gravure washing solution and preparation method thereof

An environment-friendly, high-performance technology, applied in chemical paint/ink remover, coating, etc., can solve problems affecting production safety, oil and gas escape, demulsification, etc., to protect the environment, reduce consumption, clean and decontaminate powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

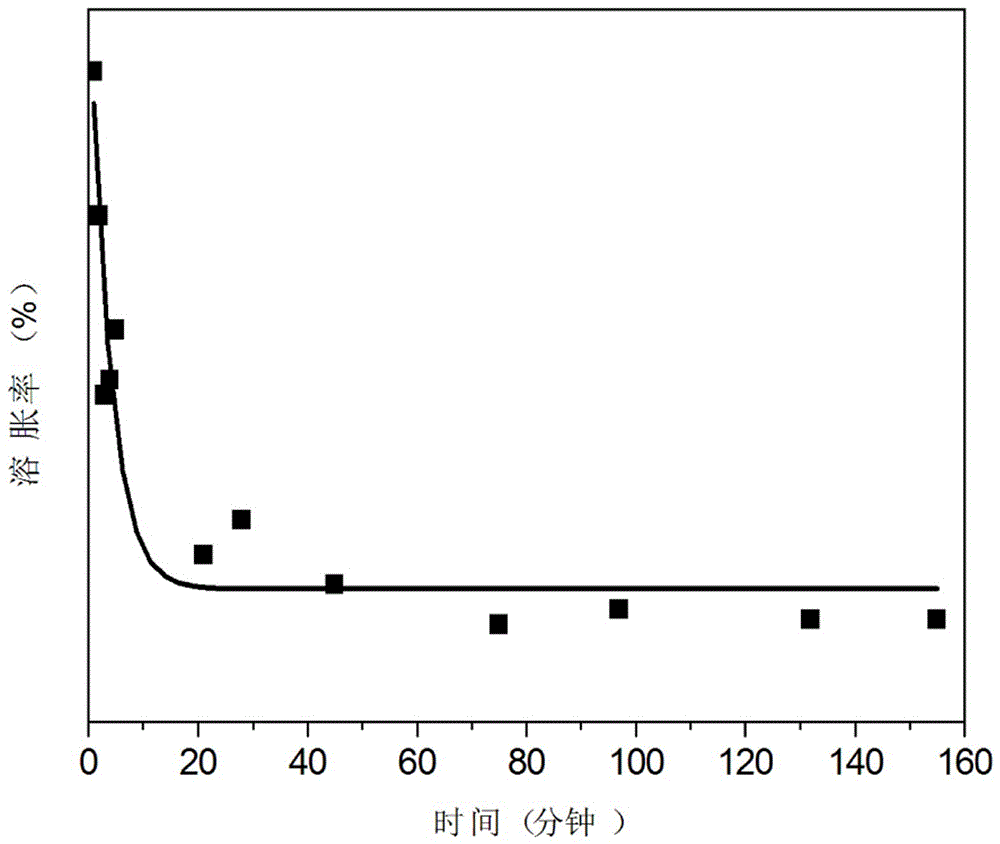

Image

Examples

Embodiment 1

[0025] A high-performance environment-friendly water-based gravure plate washing solution, using the following components in parts by weight: 6 parts of non-ionic surfactants, 3 parts of anionic surfactants, 1 part of cosolvent, and 2 parts of washing auxiliaries , 0.3 parts of defoamer, 0.3 parts of ethylenediaminetetraacetic acid, and 60 parts of water.

Embodiment 2

[0027] 8 parts of nonionic surfactants, 5 parts of anionic surfactants, 2 parts of cosolvents, 4 parts of washing auxiliaries, 0.5 parts of defoamer, 0.4 parts of EDTA, and 70 parts of water.

Embodiment 3

[0029] 10 parts of nonionic surfactants, 6 parts of anionic surfactants, 3 parts of cosolvents, 6 parts of washing auxiliaries, 0.7 parts of defoamer, 0.6 parts of EDTA, and 90 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com