Microchannel cooling device of kilowatt level optical fiber laser

A fiber laser and cooling device technology, applied in the field of cooling devices, can solve problems such as fiber side burnout, fiber laser not working normally, output wavelength change, etc., and achieve the effects of prolonging service life, obvious cooling effect, and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

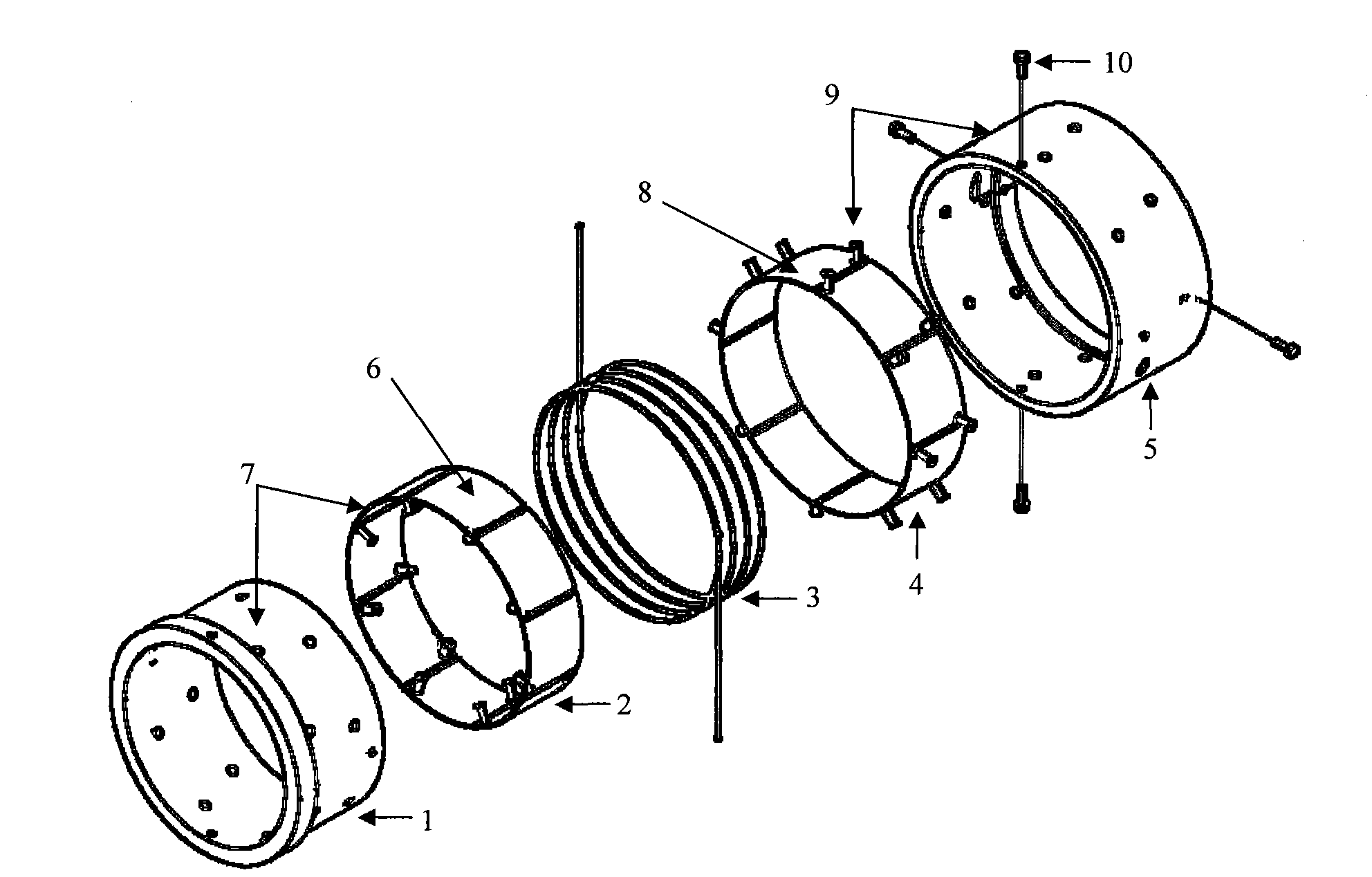

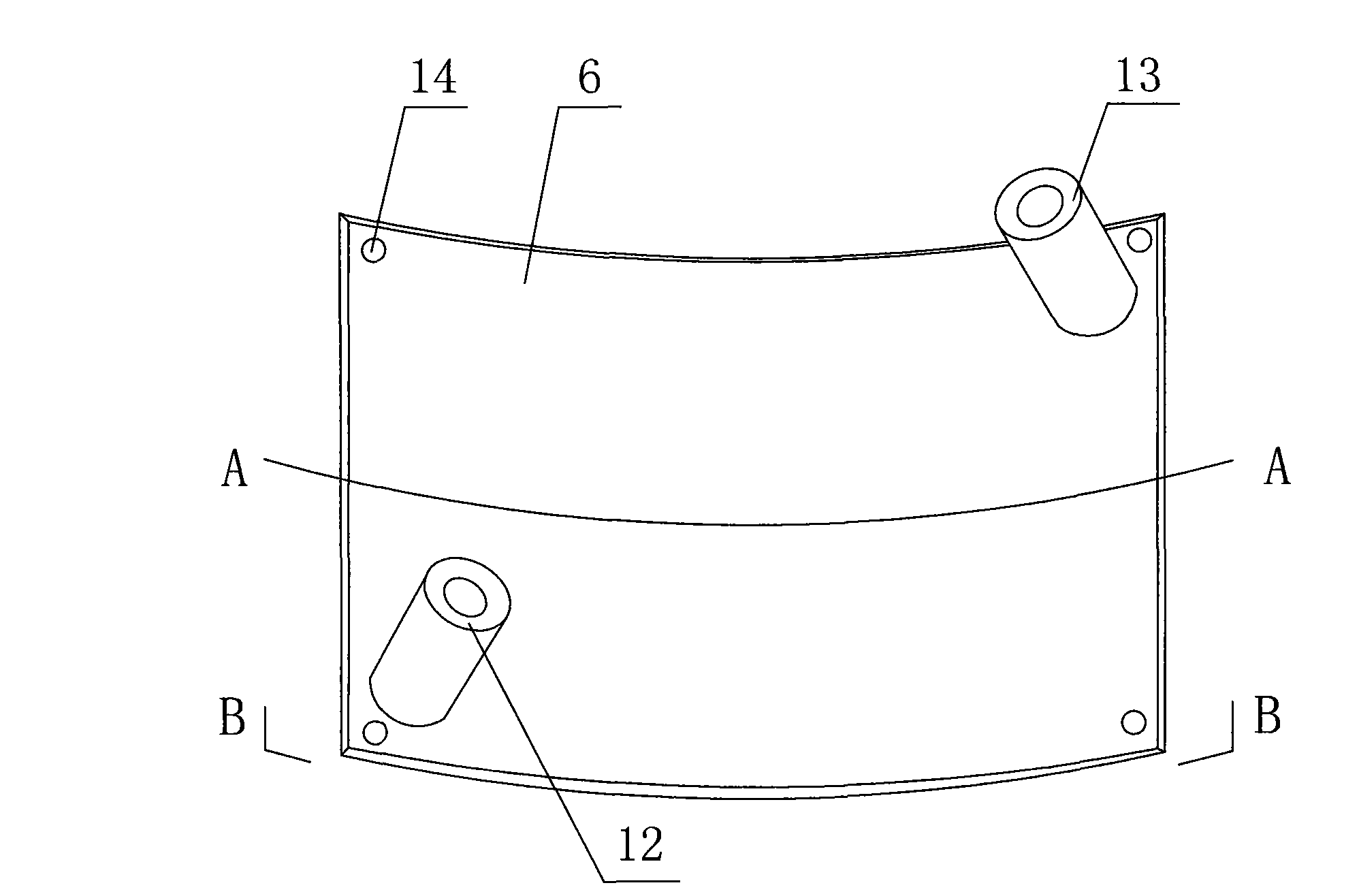

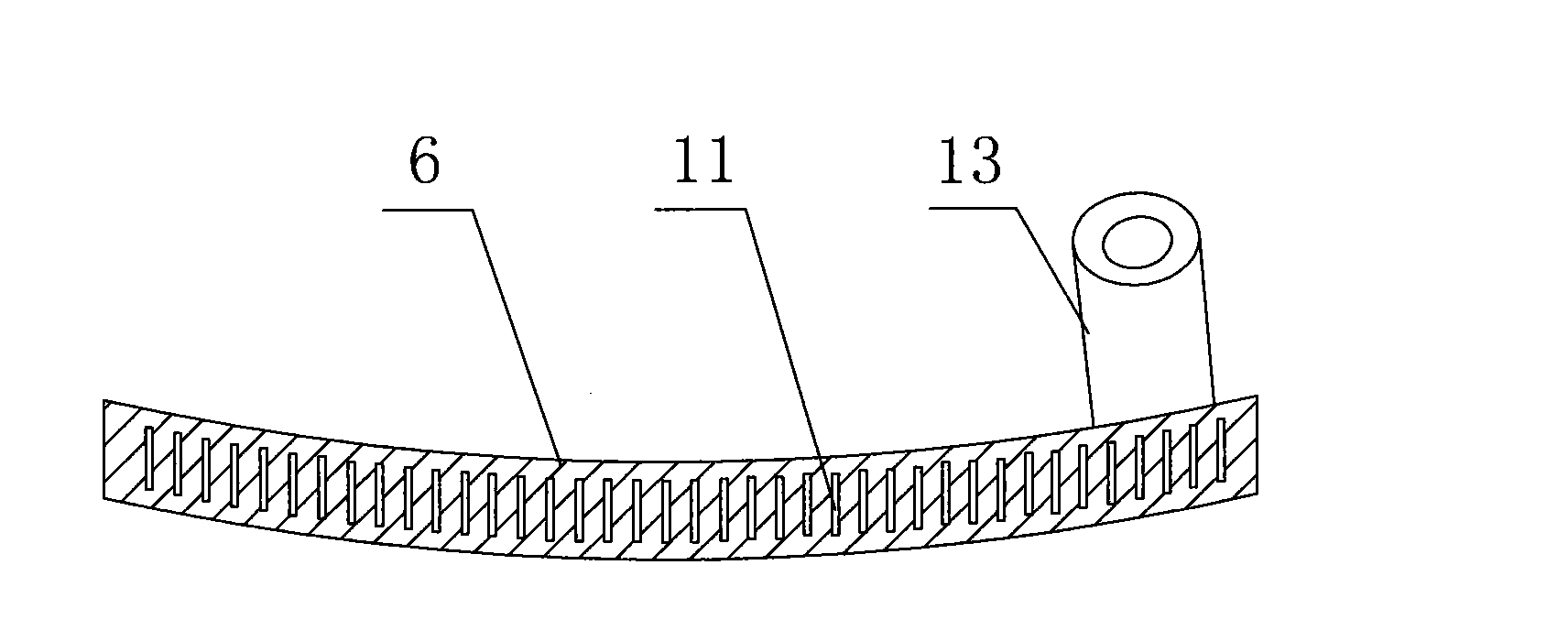

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the kilowatt-class fiber laser microchannel cooling device includes an inner cooler 7 and an outer cooler 9, and the outer cooler 9 is set on the inner cooler 7; when in use, the fiber laser 3 (kilowatt-class fiber laser) is located inside between the cooler 7 and the outer cooler 9, and the fiber laser 3 is wound on the inner cooler 7 and is in contact with the outer cooler 9; the input end of the fiber laser 3 passes through the optical fiber input hole on the outer cooler 9 and is located outside Outside the cooler 9, the output end of the fiber laser 3 passes through the optical fiber output hole on the outer cooler 9 and is positioned outside the outer cooler 9; the outer cooler 9 and the inner coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com