Nano water ion generating device

An ion generating device and nano-water technology, which is applied to machines that use electric/magnetic effects, machine operation methods, electrical components, etc., can solve the problem of inability to manufacture nano-water ions stably for a long time, inability to exert water absorption/retaining effects, Increase the difficulty of assembly or processing to achieve the effect of improving refrigeration efficiency and cold transfer efficiency, ensuring long-term safe operation, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

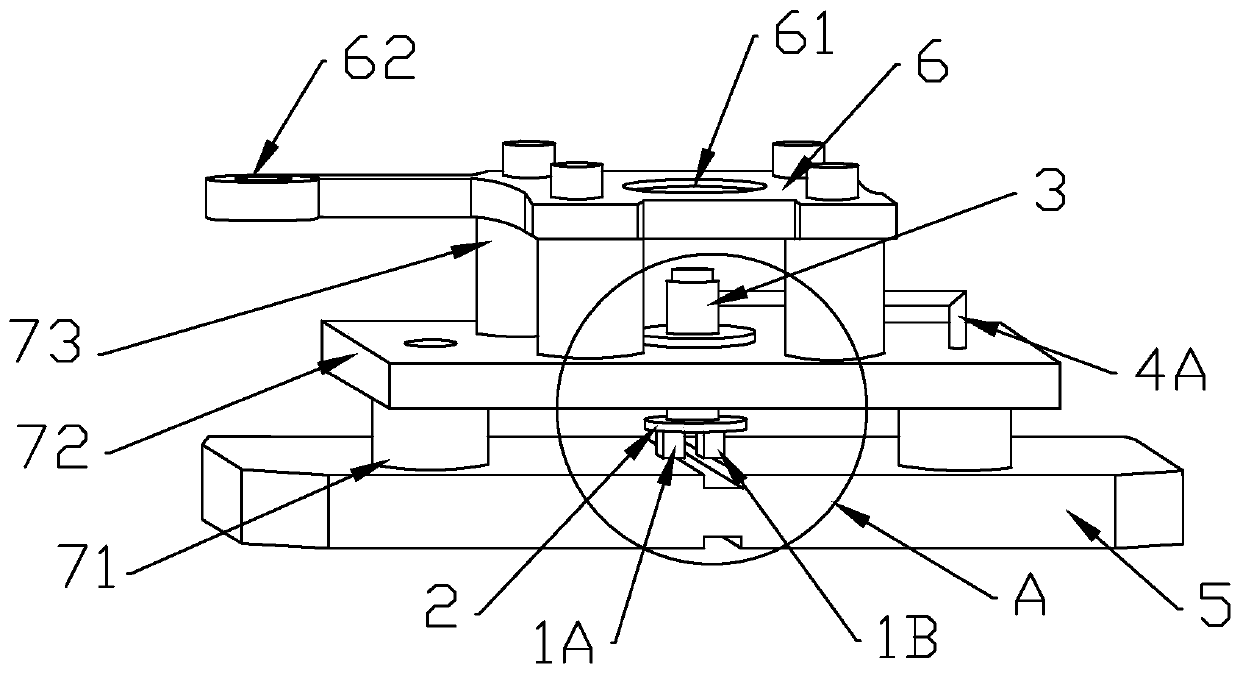

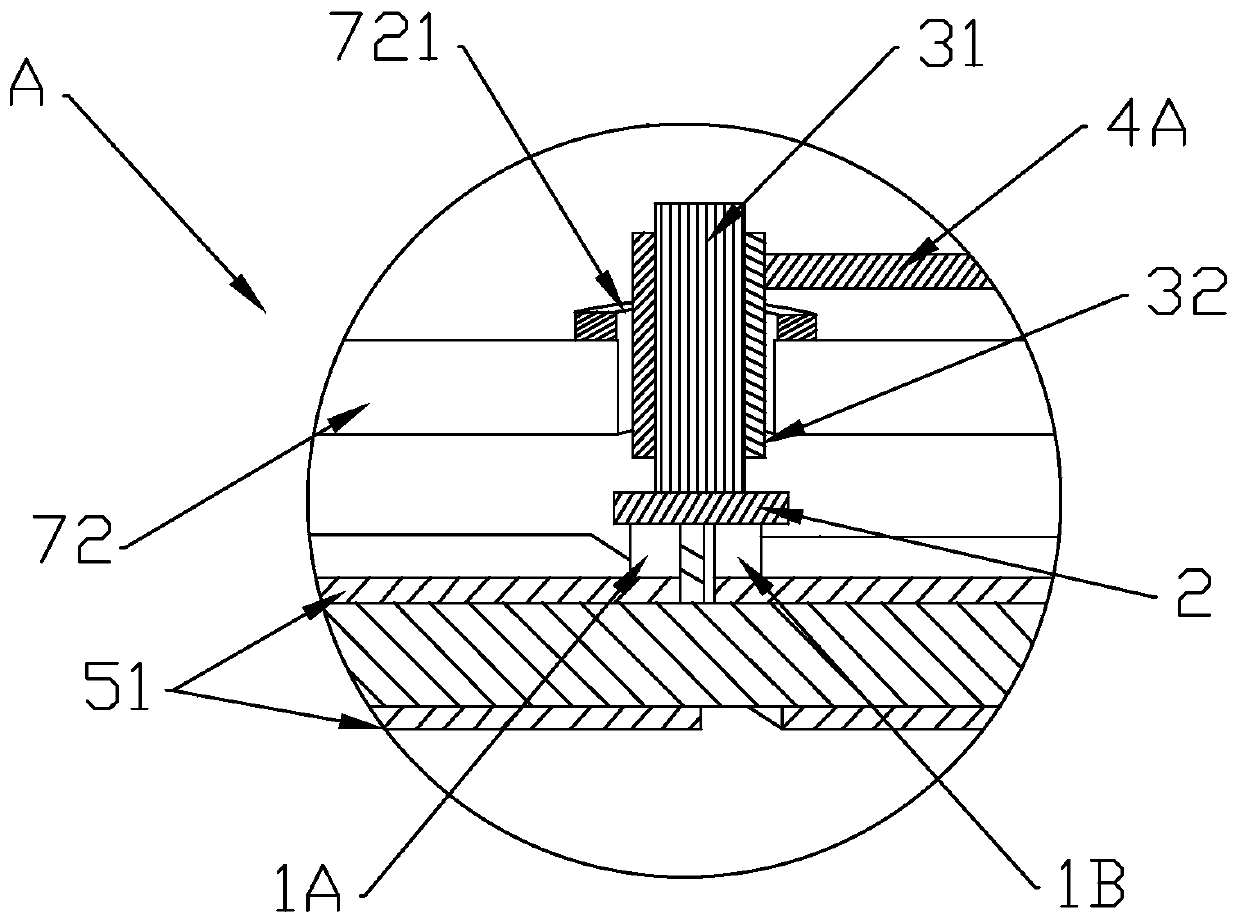

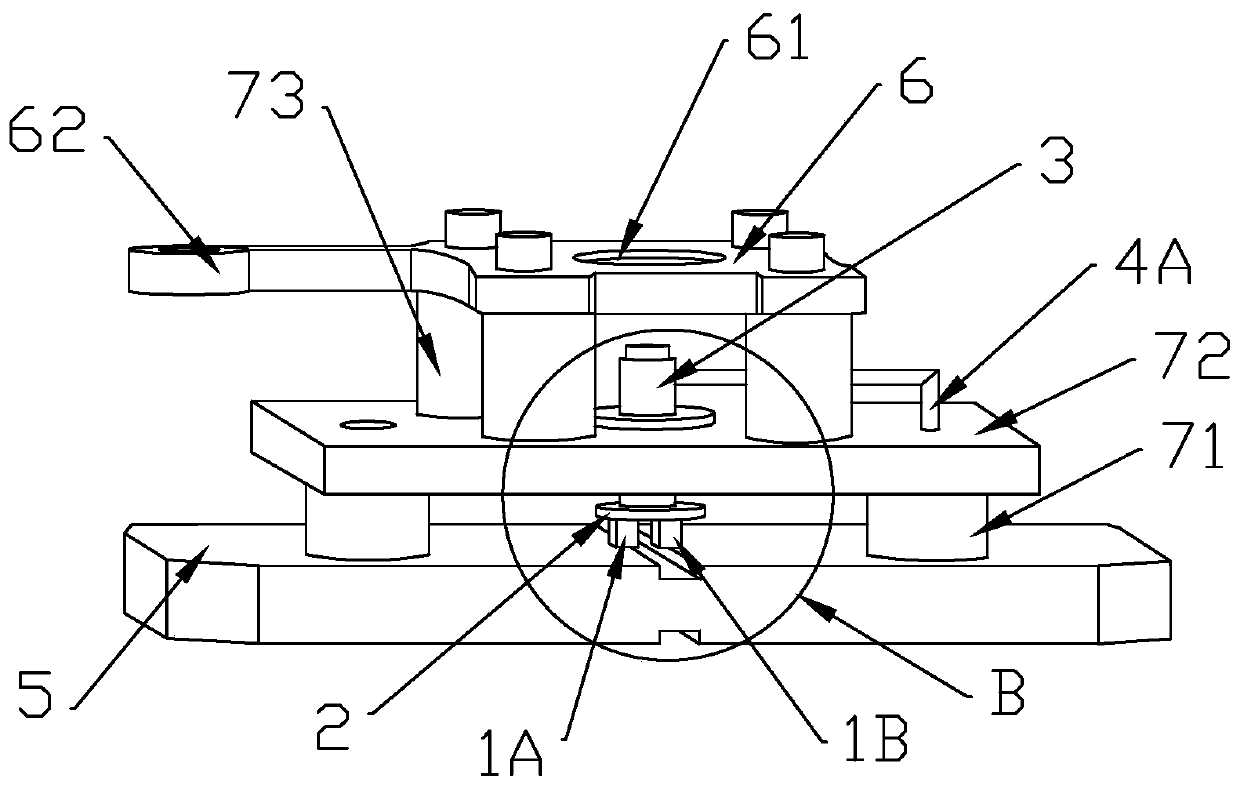

[0036] refer to figure 1 , 2 , the present embodiment provides a nanometer water ion generating device, including a pair of semiconductor grains composed of a P-type semiconductor 1A and an N-type semiconductor 1B, one end of the semiconductor grain pair is a cooling end, and the other end is a heat dissipation end ; Also includes a condensation pan 2, a discharge electrode 3 and a constant voltage electrode; the condensation pan 2 is electrically connected to the cooling end of the semiconductor crystal grain pair; the discharge electrode 3 is arranged above the condensation pan 2 One end of the discharge electrode 3 is a water-absorbing end, and the water-absorbing end is close to the condensation plate 2, and the other end of the discharge electrode 3 is a discharge end; the constant voltage electrode is arranged on the side of the discharge electrode 3 .

[0037]Specifically, during the working process, the temperature at the condensation pan 2 is slightly lower than the...

Embodiment 2

[0063] refer to image 3 , 4 , on the basis of the first embodiment, this embodiment also includes a positioning pin 21, and the positioning pin 21 is arranged on the condensation pan 2.

[0064] Specifically, the positioning pin 21 can be integrally formed with the condensation pan 2 or welded and fixed to the center of the condensation pan 2 to support and position the discharge electrode 3, and the positioning pin 21 with a lower temperature can also be Liquid droplets are directly condensed on the conductor wires / bundles 31 inside the discharge electrode 3 to increase the amount of condensed water.

Embodiment 3

[0066] refer to Figure 5 , 6 , on the basis of Embodiment 1, the constant voltage electrode 4B used in this embodiment is a conductor perpendicular to the discharge electrode 3, and the constant voltage electrode 4B points to one end of the discharge electrode 3 and the The conductor cladding layer 51 on the side close to the pair of semiconductor crystal grains is electrically connected, and the other end of the constant voltage electrode 4B is electrically connected to the regulated power supply.

[0067] Specifically, the side of the constant voltage electrode 4B pointing to the discharge electrode 3 is fixed on the support table 72 by screws, and is electrically connected to the conductor coating 51 on the side close to the pair of semiconductor crystal grains.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com