Structure of lightning protection grounding network in karst area and manufacturing method thereof

A technology of lightning protection grounding and manufacturing method, which is applied to grounding devices, substation grounding arrangements, connecting contact materials, etc., can solve the problems of high price, difference in resistivity variation range, affecting resistivity, etc., and achieves low cost and simple operation. , the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

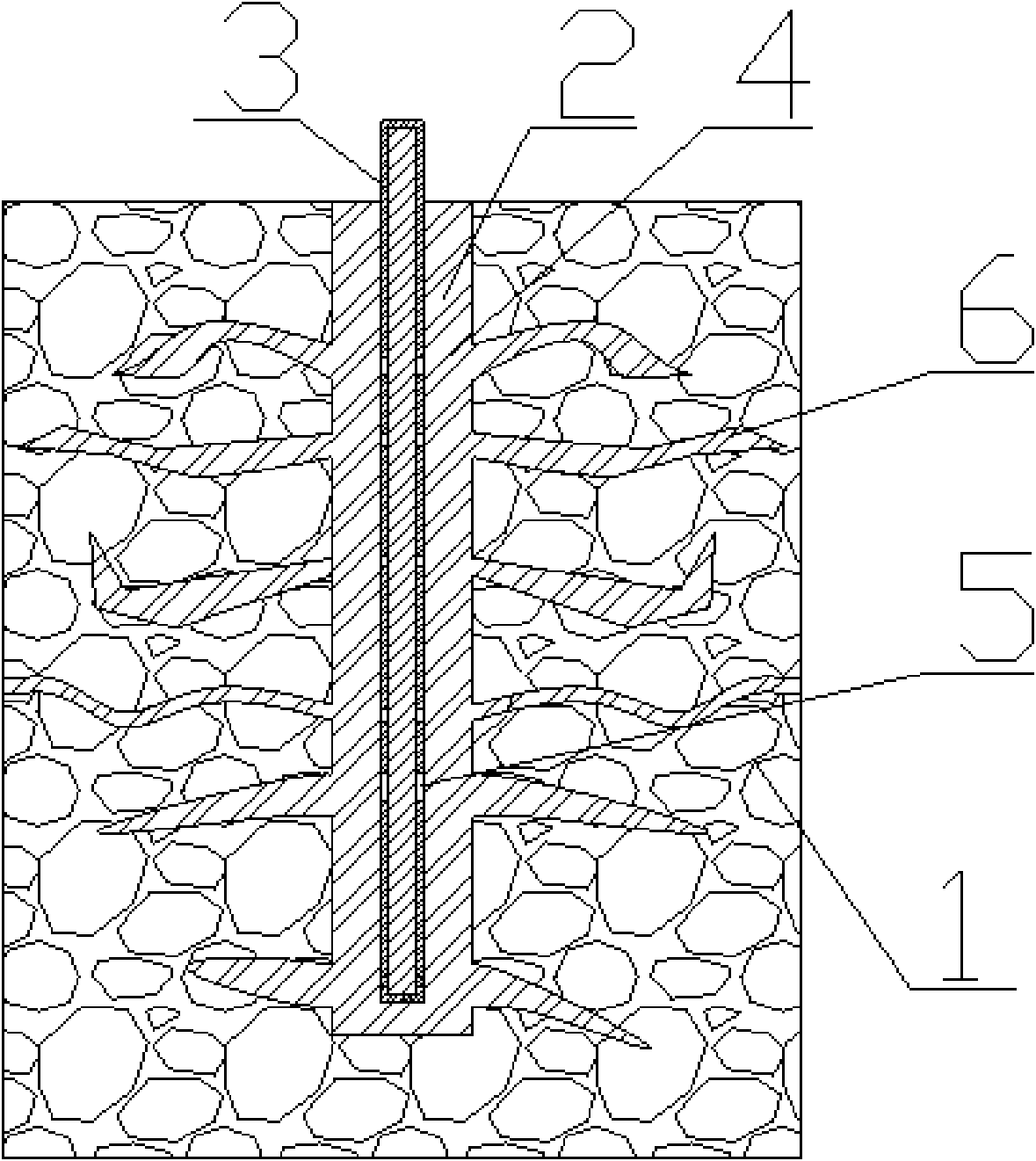

[0014] Example: such as figure 1 As shown, a deep well 2 is first opened with drilling equipment in the lightning protection area 1 of the karst area. Make a hollow tubular metal electrode 3 at a depth of 100 mm, and the metal electrode 3 is made of a copper tube with a pipe diameter of φ35~φ100 mm. According to the sampling results of the geological layer, the penetration hole 5 on the metal electrode 3 is opened, so that the metal electrode 3 that is put into the deep well 2 The position of the permeable hole 5 on the electrode 3 corresponds to the position of the rock section layer 6 in the geological layer. After the metal electrode 3 is placed in the deep well 2, the grouting equipment is used to connect the metal electrode 3 so that the resistance reducing material 4 moves along the metal electrode. The seepage hole 5 on the 3 is pressed into and fills up the deep well 2 and the rock section layer 6, and the drag-reducing material 4 used is a physical drag-reducing agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com