Rotary moving member

A moving part, rotary technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as increased workload, inconvenient operation, and difficulty in adapting to positioning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

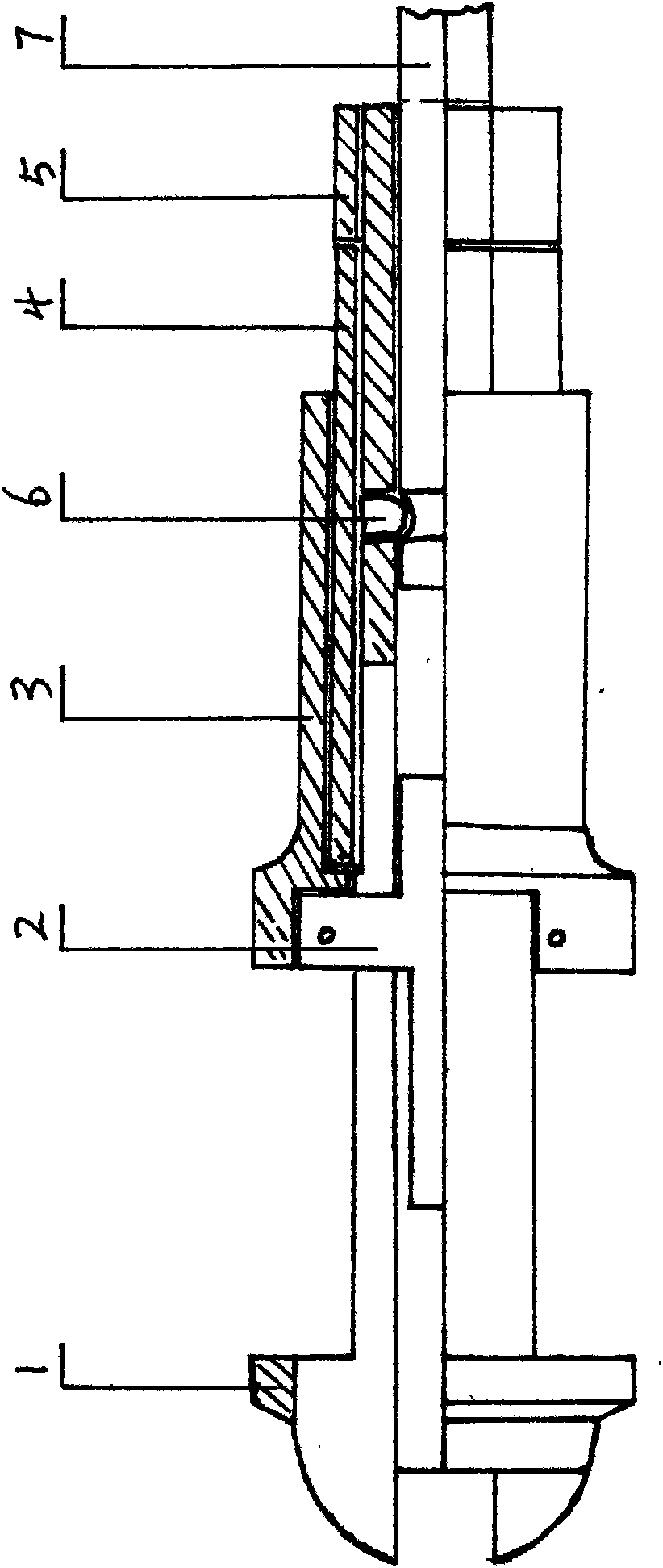

[0006] A rotary moving part, including the middle hole rotating head 1, the middle hole is equipped with a rod transmission piston 2 connected with a movable round handle 3, and the adjusting fixed sleeve 4 is connected with the rod of the middle hole rotating head 1, and there is a locking The cap 5 is connected with the lock buckle 6 and is rotatable at the center of the fixed connecting rod 7 at the same time.

[0007] Rotary head with middle hole 1, rod-passing piston 2 is installed in the middle hole, and a movable round handle 3 is connected to push it forward. When the weldment is finished welding, it is pushed by the transmission rod piston 2, and then protrudes from the center hole rotary head 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com