Coolant circulation energy-saving device for automatically recovering aluminum scraps

An automatic recovery and coolant technology, applied in the direction of filtration circuit, maintenance and safety accessories, filtration and separation, etc., can solve the problems of a lot of accumulation, waste, and must be shoveled with a shovel and transported away in a special plastic bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

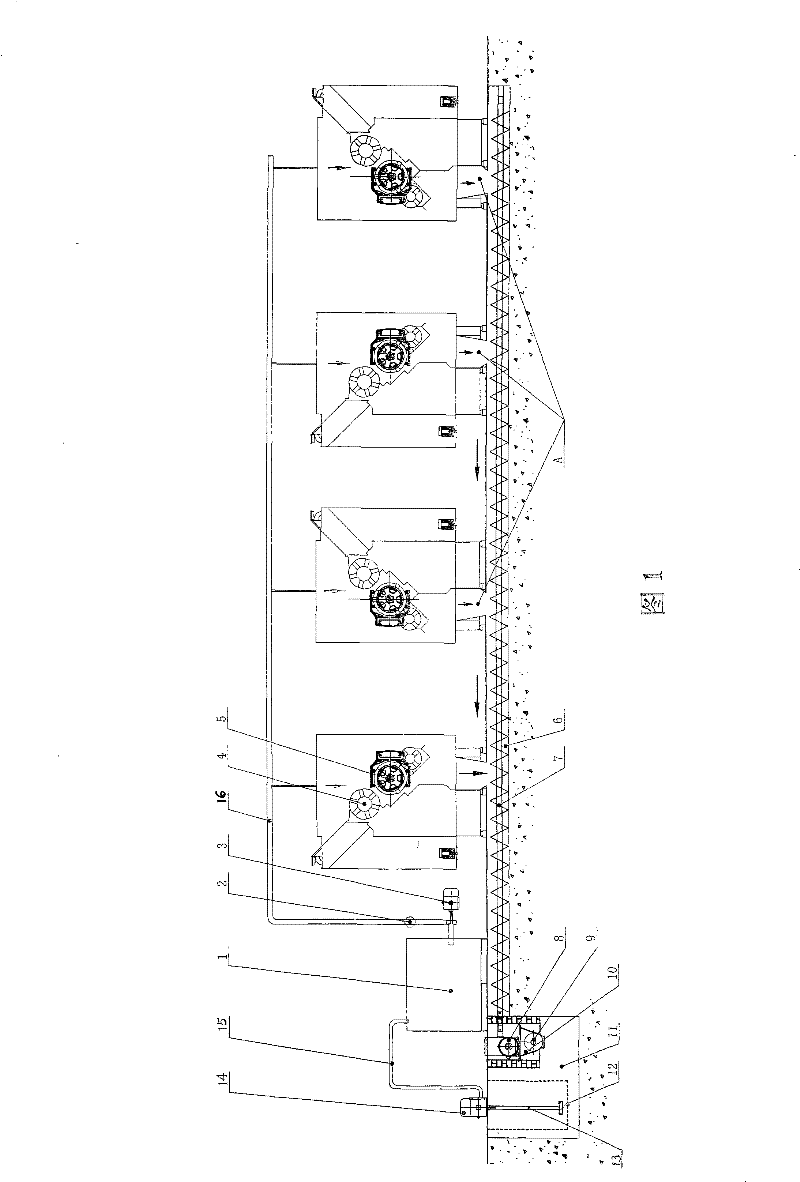

[0009] Below in conjunction with the accompanying drawings, the specific implementation process of the cooling liquid circulation energy-saving device for automatically recovering aluminum scraps of the present invention will be further described: Driven and started to move synchronously after being shifted by the reducer 8, specifically, the edge of the spiral blade of the chip cleaning auger 7 is close to the inner edge and bottom of the ground groove 6 and moves in the direction of the separation groove 11; at this time, the cut aluminum Chips and cooling fluid for lubricating and cooling fall from the outlet A at the bottom of several CNC lathes 5 into the ground groove 6, and are continuously pushed and discharged by the blades of the chip cleaning auger 7 in the ground groove 6 into the separation The groove 11 is separated: the aluminum chips fall into the aluminum chip storage tank 10, and then are pushed into the aluminum chip packaging bag by the blade of the chip rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com