Tiltrotor controlled by double-propeller vertical duct

A dual-propeller and tilt-rotor technology, which is applied to rotorcraft, aircraft, motor vehicles, etc., can solve the problems of short control force arm, complex control mode, unfavorable safety and reliability of the structure and control mode of tilt-rotor aircraft, etc. problem, to achieve the effect of reducing the size of the duct and reducing the flight resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

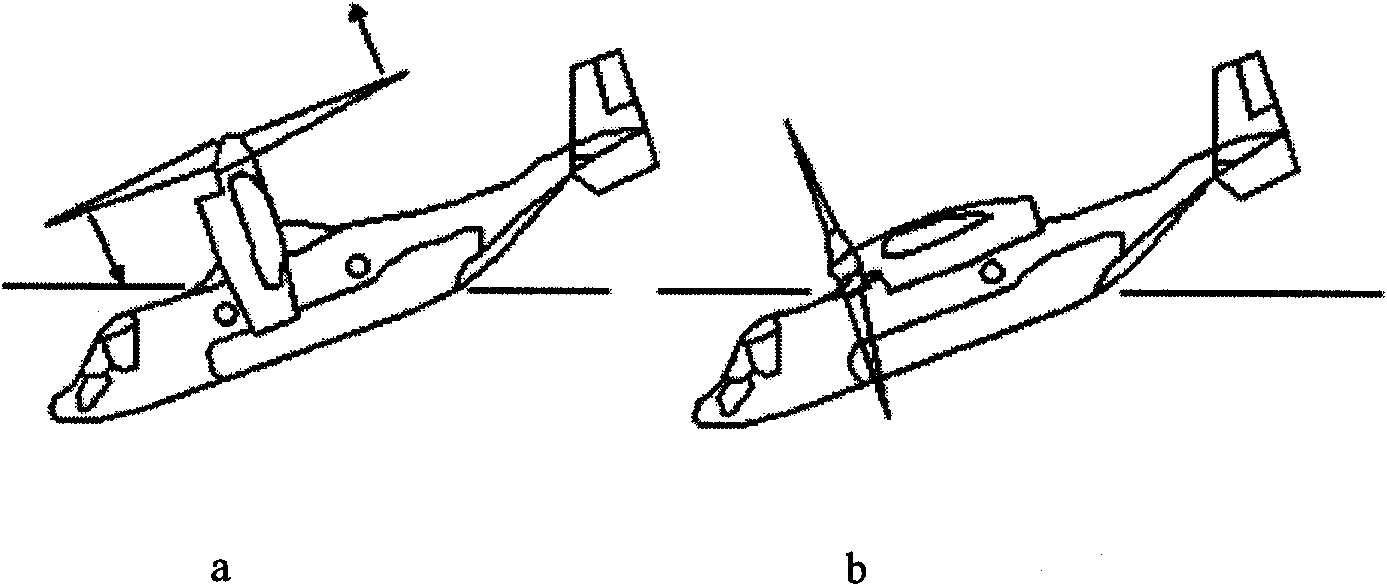

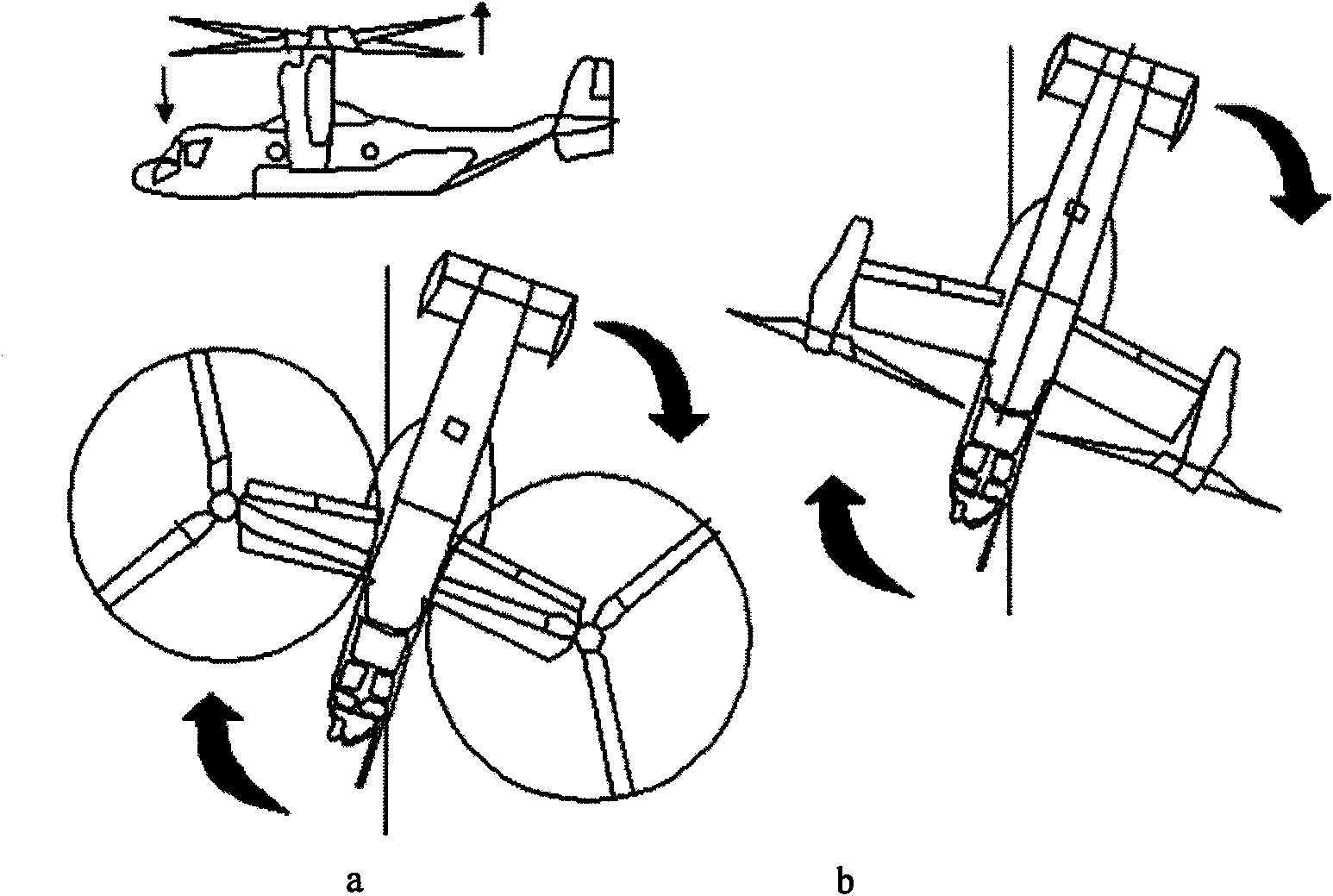

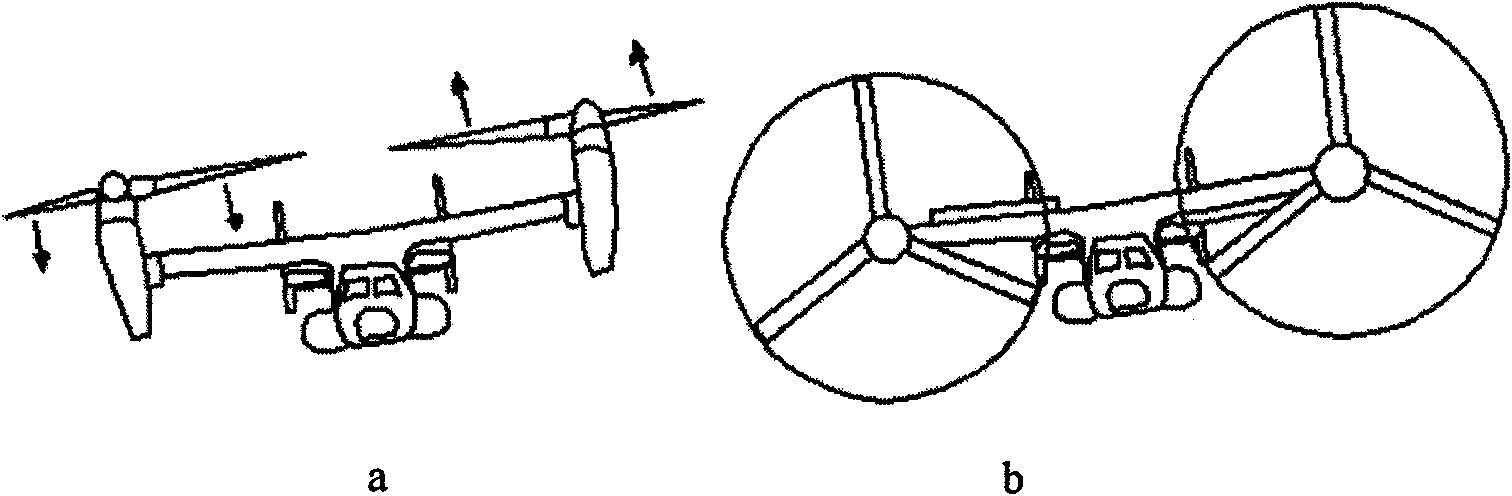

[0058] See Figure 4 ~ Figure 8 Shown, the present invention uses a kind of tilt rotor aircraft controlled by double propeller vertical duct, this aircraft adopts the design of side by side double rotor, conventional aerodynamic layout, and it is made of fuselage 1, straight wing 2, rotor 3, short Cabin 4, aileron 5, vertical tail 6, rudder 7, elevator 8, horizontal tail 9, landing gear 10, power and deceleration system 11 and double propeller vertical duct structure 12. The straight wing 2 is installed on both sides of the middle section of the fuselage 1, the rotor 3 is installed on the end of the nacelle 4, the main body of the landing gear 10 is located at the belly of the fuselage 1, and the straight wings 2 on both sides of the fuselage 1 support the The nacelle 4 at the end, the aileron 5 is connected to the outside of the wing 2, the horizontal stabilizer 9 is connected to the tail of the fuselage 1, the elevator 8 is connected to the rear of the horizontal stabilizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com