CO* flooding single string multi-zone separate injection technical string

A process pipe string, CO2 technology, applied in drilling pipe, casing, production fluid and other directions, can solve the problems of low injection efficiency, poor corrosion resistance, prominent contradiction between layers, etc., to achieve low pipe string cost and simple construction process , The effect of reliable sealing performance of the pipe string

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

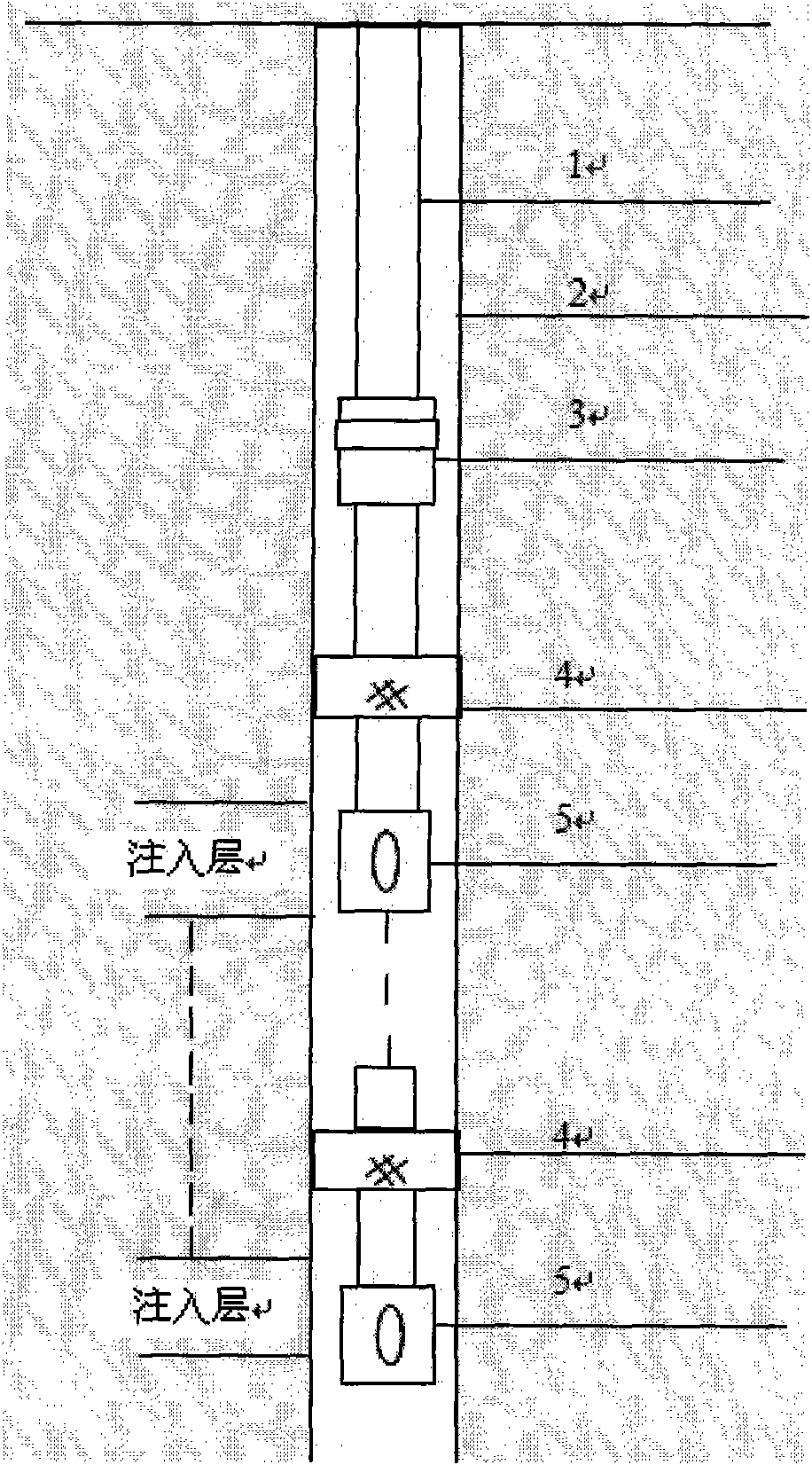

[0009] As shown in the accompanying drawings, the present invention includes an oil pipe 1 and a casing 2, and the oil pipe 1 is placed in the casing 2, and it also includes an alternate injection regulator 3, a packer 4 and a dispenser 5, wherein the lower end of the oil pipe 1 is sequentially Connect alternate injection regulator 3, packer 4, and injector 5, connect multiple unit bodies composed of packer 4 and injector 5 under injector 5, and inject regulator 3, packer 5 alternately Both the device 4 and the dispenser 5 are connected by oil pipes.

[0010] Packer 3 is a drillable Y443 type. The tubing 2 is treated with a nickel-phosphorous coating.

[0011] During on-site construction, when the tubing string is lowered to the predetermined position in the casing, the tubing 1 is pressed to 15-20MPa, and the packer 4 is equipped with a hydraulic setting system to compress the rubber cartridge, and the multi-stage packer 4 is completed in one trip. For setting, the injector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com