Pull-type elevating mechanism

A technology of lifting mechanism and locking mechanism, which is applied in spraying devices and other directions, can solve the problems of inconvenient use for the elderly, children or disabled people, easy loss of elasticity of elastic sleeves, and affecting the service life of showers, etc., so as to prolong the service life and reduce the production process , to ensure the effect of self-locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

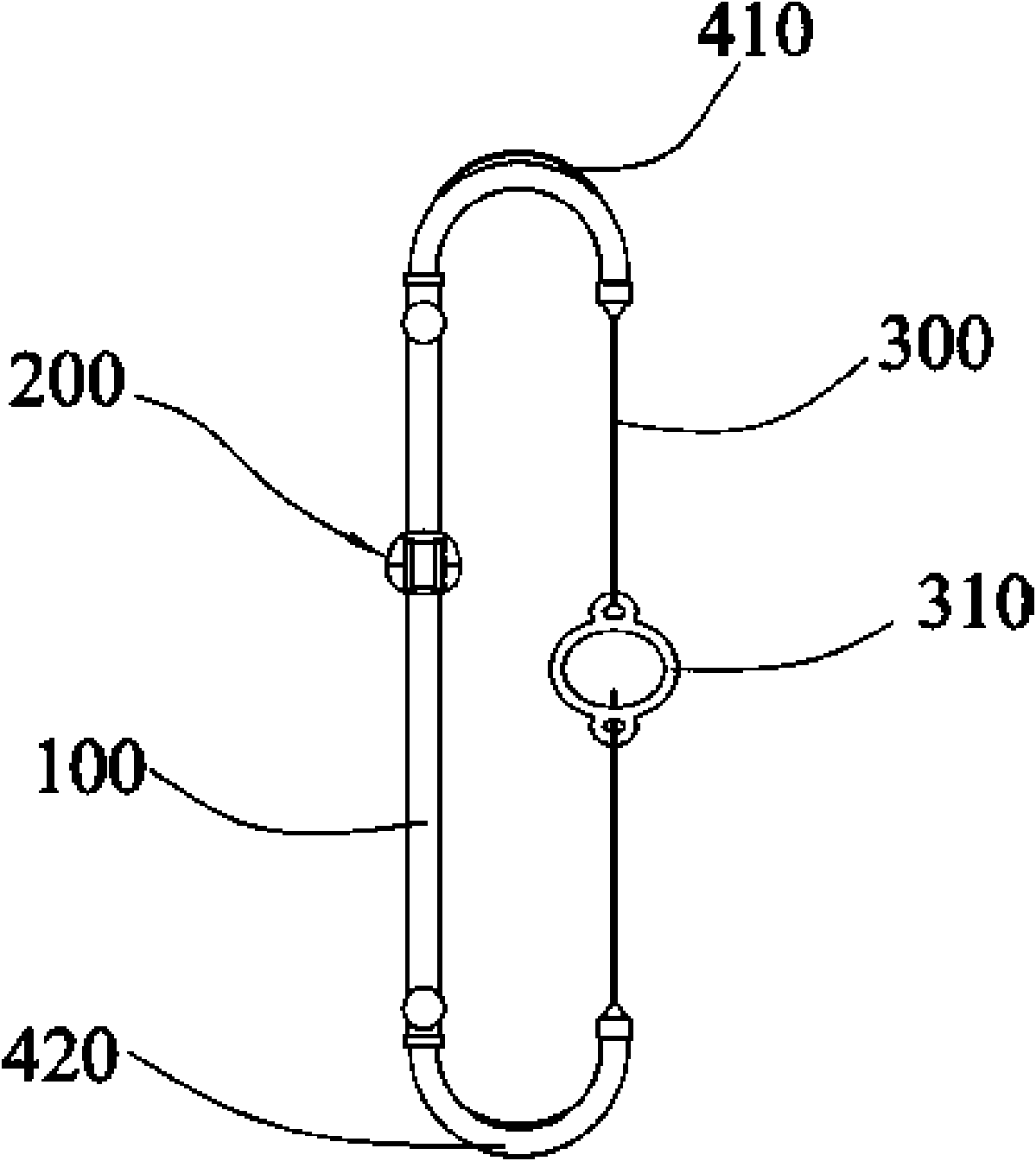

[0037] see Figure 1 to Figure 5 , is a schematic diagram of a preferred embodiment of the pull-type lifting mechanism provided by the present invention.

[0038] combine figure 1 and Figure 5 As shown, the pull-type lifting mechanism includes a fixed tube 100, a self-locking mechanism 200, a pull cord 300, bent tubes 410, 420, a socket unit 500, and the like.

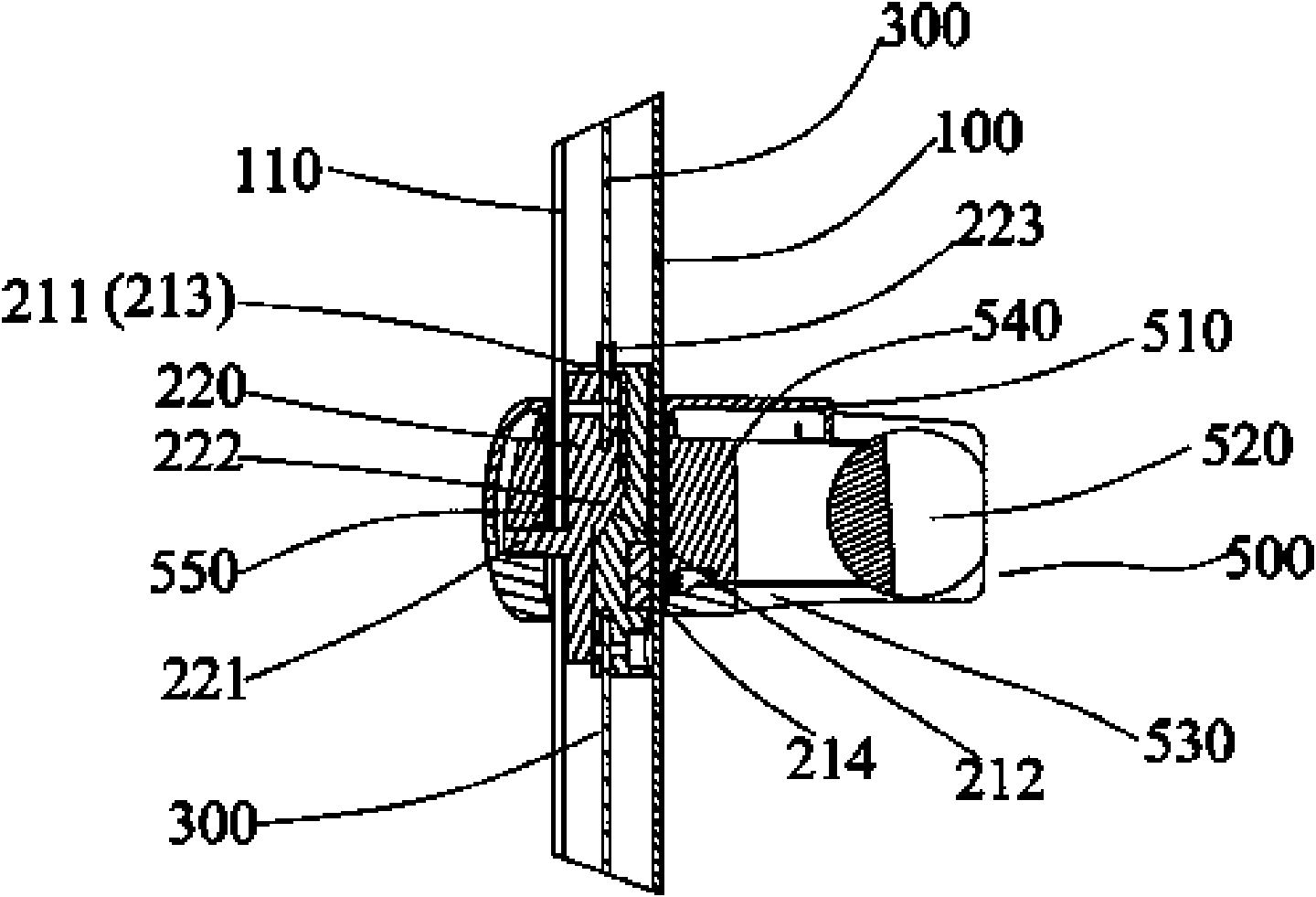

[0039] The fixed pipe 100 is provided with an axial slot 110 that runs through the inside and outside, and the head and tail ends of the fixed pipe 100 are respectively assembled with a set of wall seats 710, 720 and buckle covers 810, 820 to be fixed to the wall. Elbows 410, 420 are fixed at the head and tail ends respectively through buckles 610, 620.

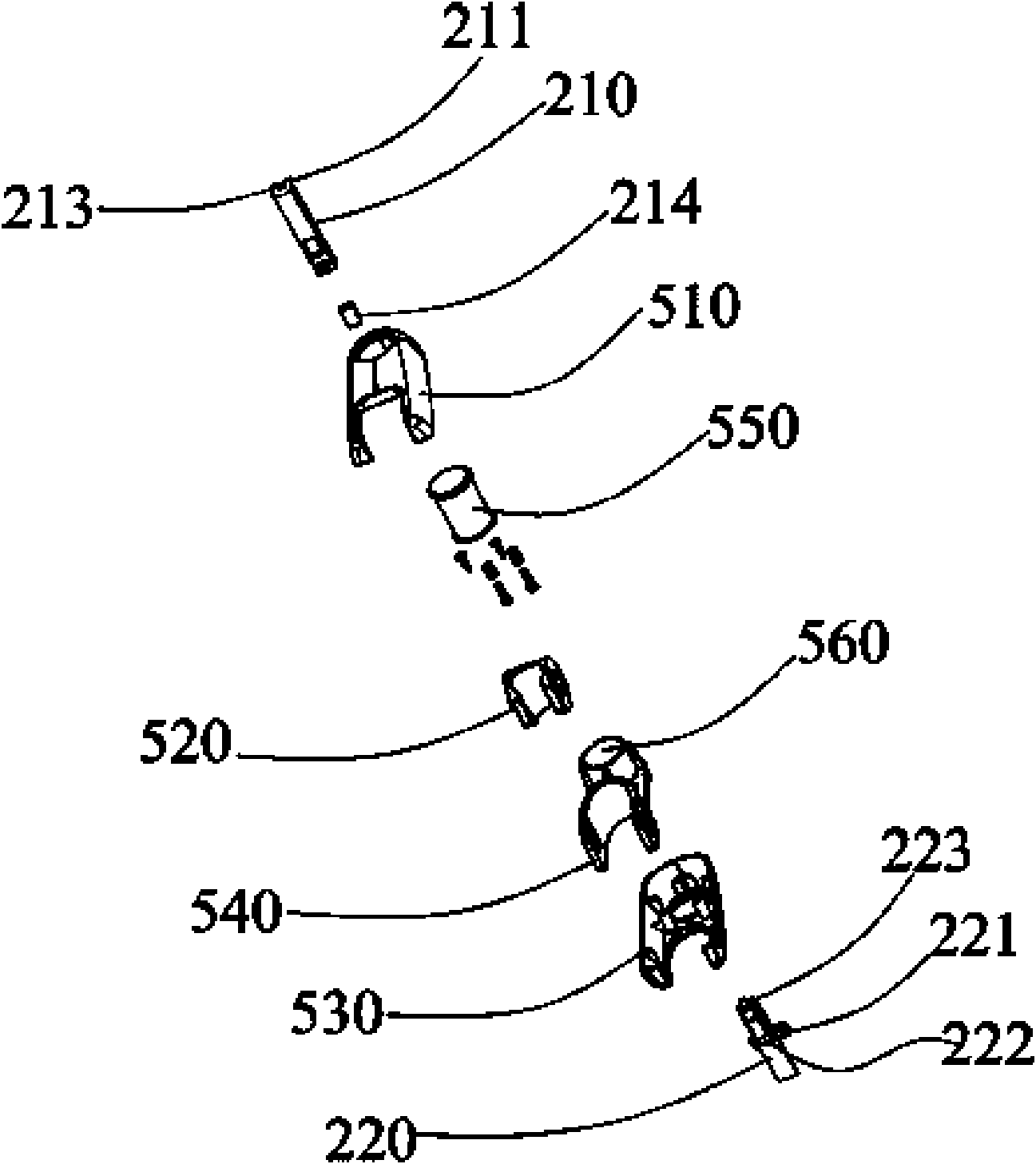

[0040] Such as figure 2 As shown, it depicts the structural relationship between the self-locking mechanism 200 and the socket unit 500 of the pull-type lifting mechanism. The self-locking mechanism 200 includes upper and lower wedge blocks 220 , 210 arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com