A compartment detachable mechanism

A technology of unloading and carriage, which is applied in the direction of vehicles with swing arms, etc. It can solve the problems of short wheelbase, high cost of lifting equipment, and low efficiency, so as to achieve a more reasonable distribution of front and rear axle loads, enhance safety and Reliability, the effect of increasing the overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

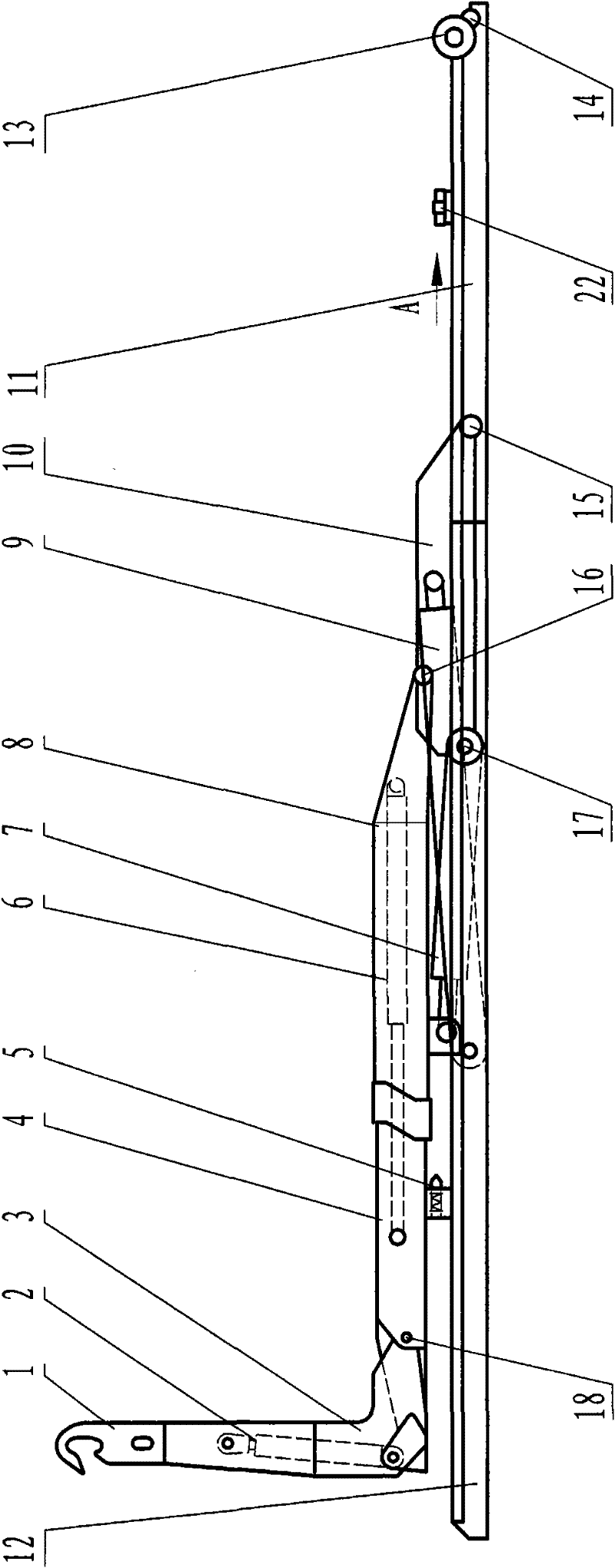

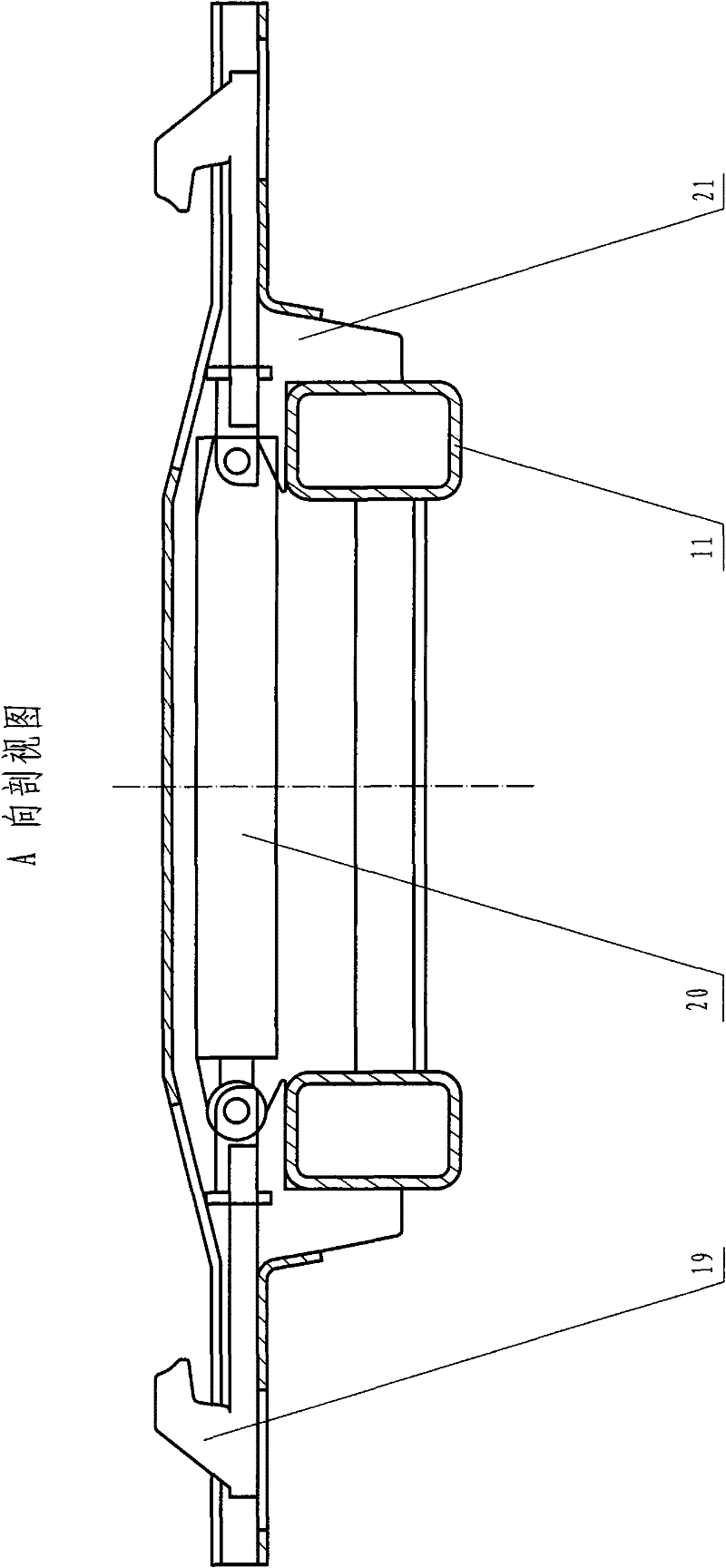

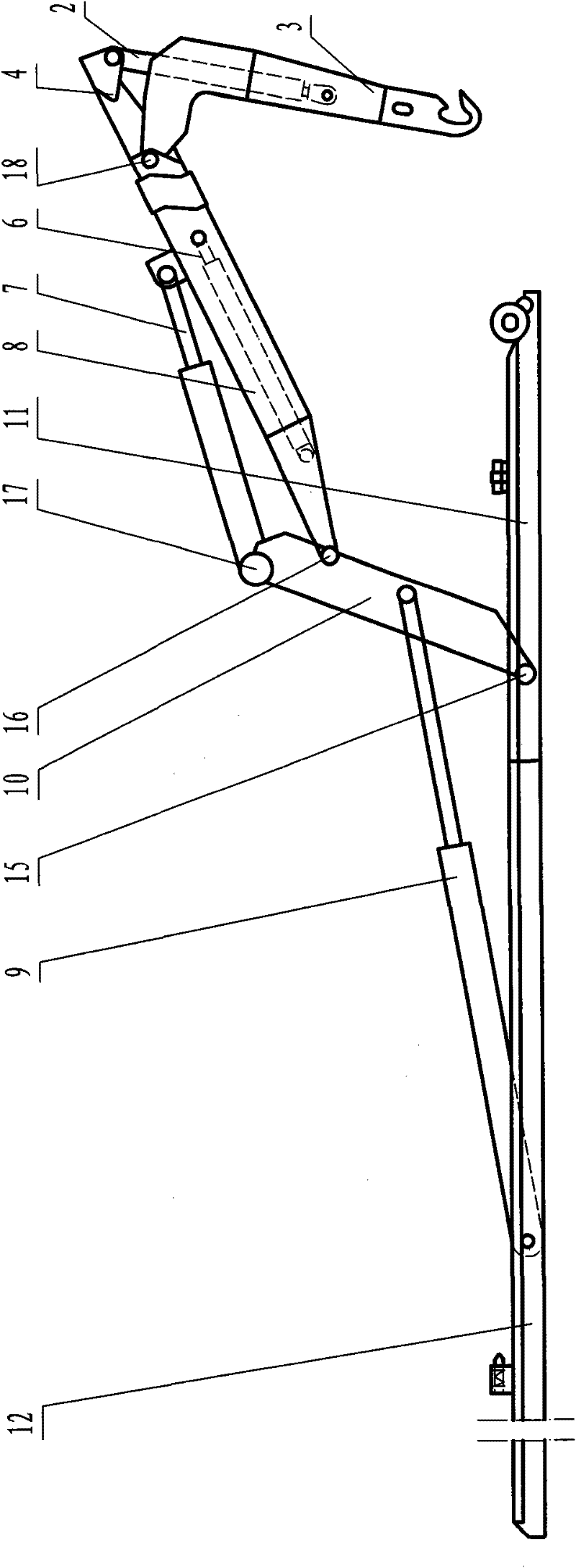

[0021] figure 1 The detachable mechanism of the carriage of the present invention includes: a swing arm assembly 3, a telescopic arm assembly 4, a lifting arm assembly 8, a folding arm assembly 10, a rotating arm assembly 11, and a subframe assembly 12 And the hydraulic system; the hydraulic system includes a swing arm cylinder 2, a telescopic cylinder 6, a lifting cylinder 9, a folding cylinder 7, a power unit and a control part. The subframe assembly 12 is installed on the automobile chassis or a special device, the rear end of the subframe assembly 12 and the rear end of the pivoting arm assembly 11 are hinged together through a pin 14, and the front end of the pivoting arm assembly 11 is connected to the folding The rear end of the arm assembly 10 is hinged together through the rotating shaft 15, the middle part of the folding arm assembly 10 and the middle front end of the subframe assembly 12 are connected together through the lifting cylinder 9, and the middle part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com