Recrystallization purifying device for lactide

A purification device and recrystallization technology, which is applied in solution crystallization, organic chemistry, etc., can solve problems such as mixing impurities and difficulties in the industrial production of lactide recrystallization, and achieve the effect of improving crystal purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

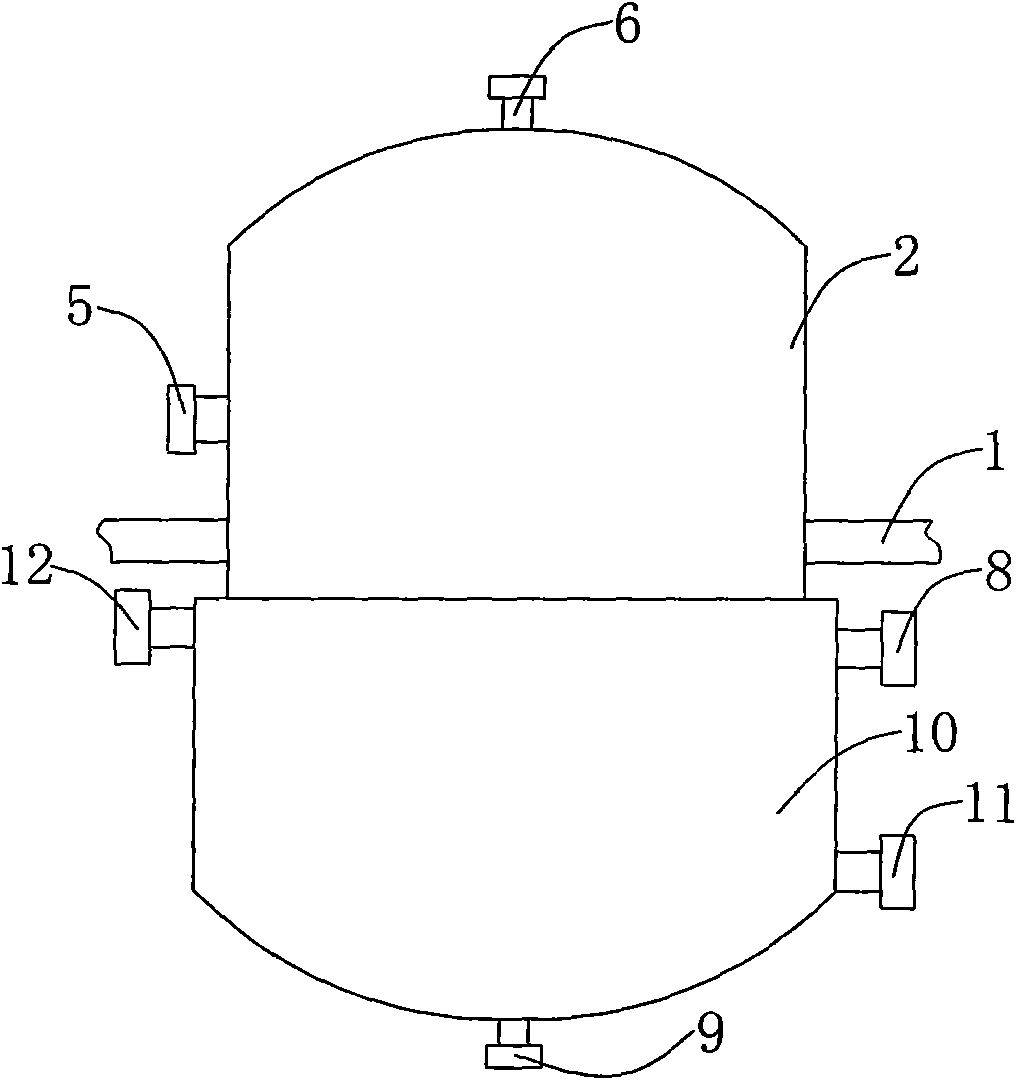

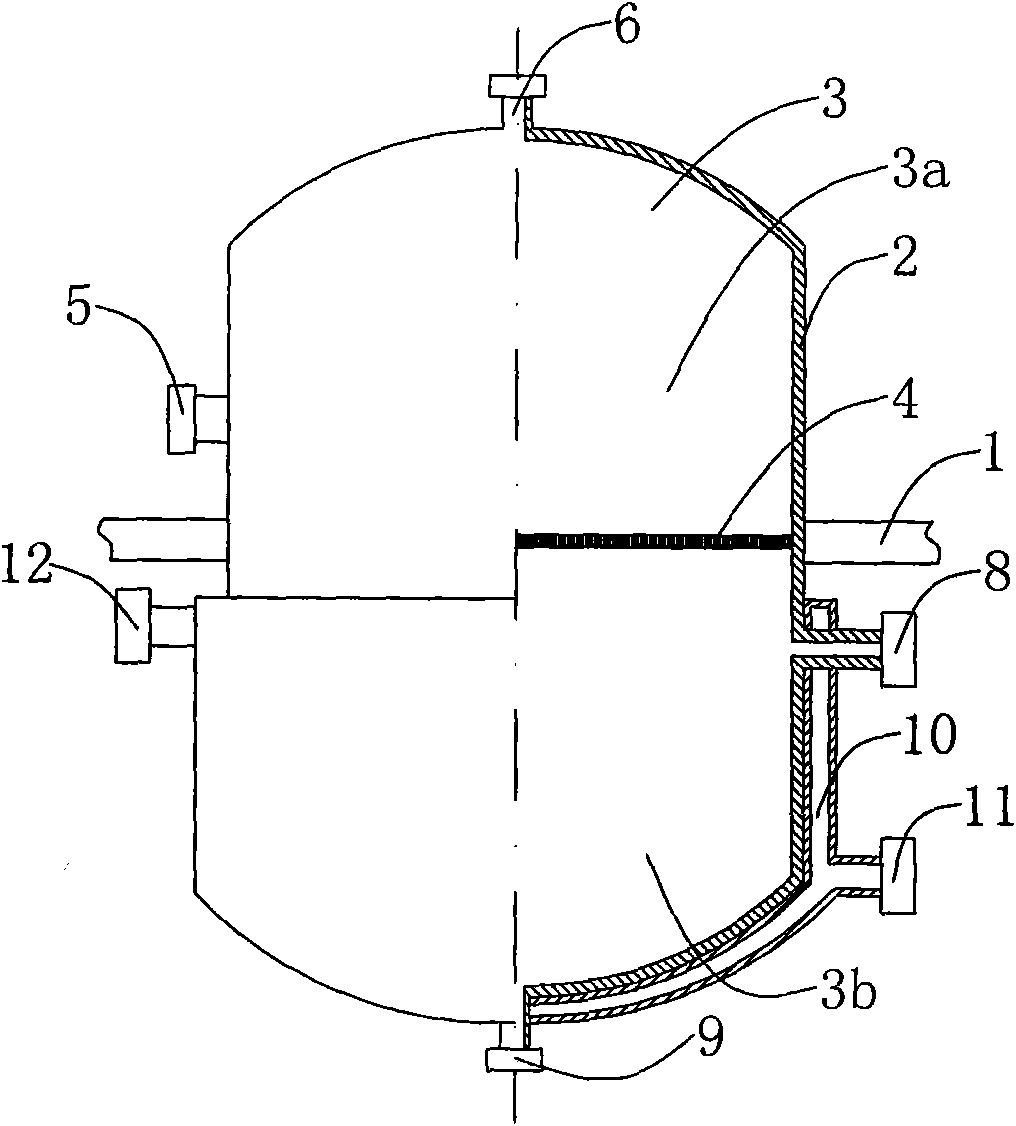

[0028] Such as figure 1 As shown, this embodiment is used for the recrystallization and purification device of lactide, which includes a tank body 2 supported by a rotating shaft 1 and capable of rotating around the rotating shaft 1 . The inner cavity of the tank body 2 constitutes a recrystallization chamber 3, and a filter plate 4 is arranged on the inner wall of the tank body 2 to divide the recrystallization chamber 3 into an upper recrystallization chamber 3a and a lower recrystallization chamber 3b. The mesh number of the filter plate 4 is between 200 mesh and 400 mesh, it is the best to not pass the lactide crystal, but the solvent can pass quickly. The tank body 2 is composed of upper and lower parts that are detachably sealed and connected, and the filter plate 4 can be replaced when the upper and lower parts are disassembled.

[0029] A recrystallization solvent inlet 5 and a suction outlet 6 are provided in the upper recrystallization chamber 3a. The pumping port ...

Embodiment 2

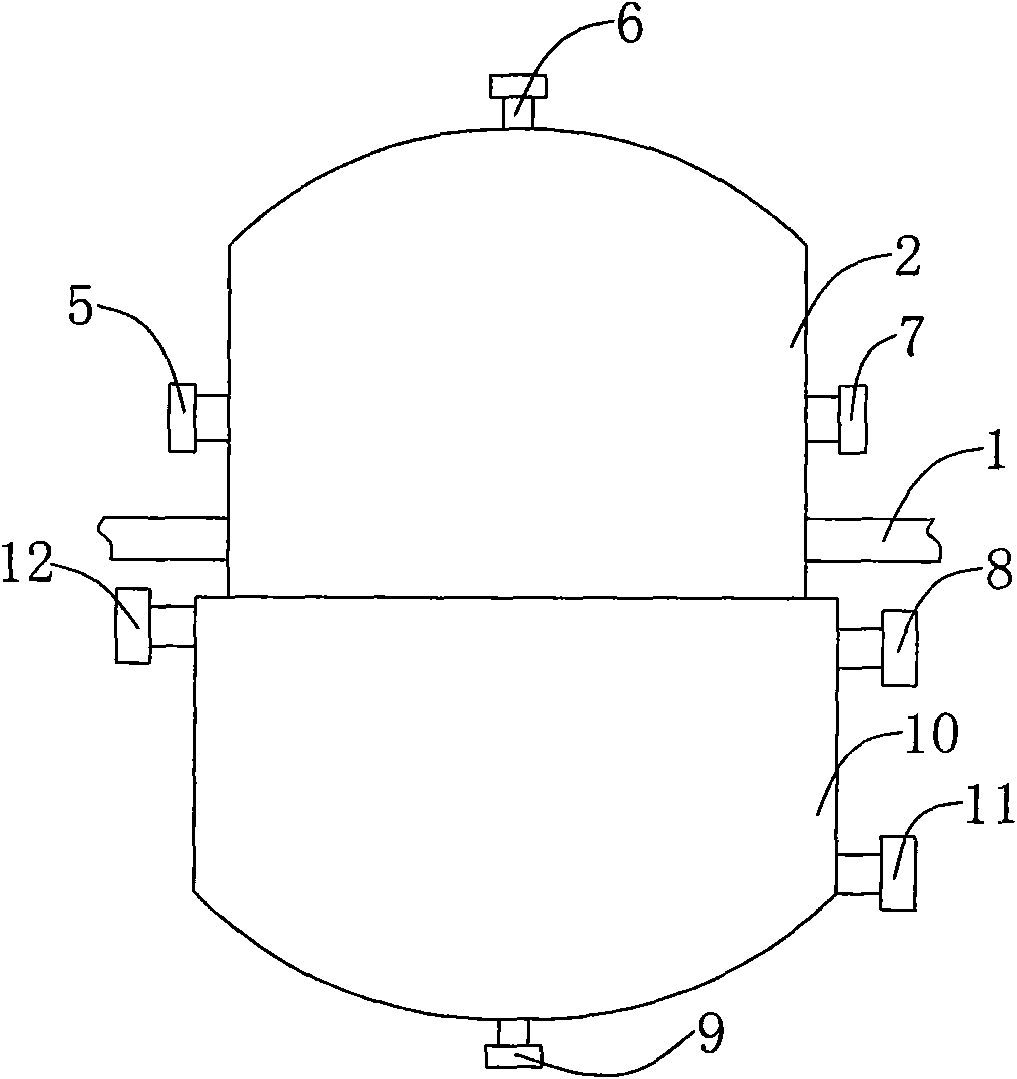

[0034] Embodiment 2 is a preferred embodiment of the present invention, as image 3 and Figure 4 As shown, the recrystallization purification device for lactide includes a tank body 2 supported by a rotating shaft 1 and capable of rotating around the rotating shaft 1. The tank body 2 is an oval tank body, and its inner cavity constitutes a recrystallization chamber 3. A filter plate 4 is provided on the inner wall of the tank body 2 to divide the recrystallization chamber 3 into an upper recrystallization chamber 3a and a lower recrystallization chamber 3b. The filter plate 4 is arranged in the middle of the recrystallization chamber 3 , and the rotating shaft 1 is fixed in the middle of the tank body 2 . The 4 mesh of the filter plate is 200 mesh to 400 mesh. The tank body 2 is composed of upper and lower parts that are detachably sealed and connected, and the filter plate 4 can be replaced when the upper and lower parts are disassembled.

[0035] A recrystallization solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com