Device for cleaning head cover of battery and method of cleaning head cover of battery

A battery and top cover technology, which is applied in the field of cleaning the battery top cover and cleaning the battery top cover, can solve the problems of increasing production costs, unfavorable long-term development of enterprises, and low cleaning efficiency, so as to avoid battery damage, reduce scrap rate, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

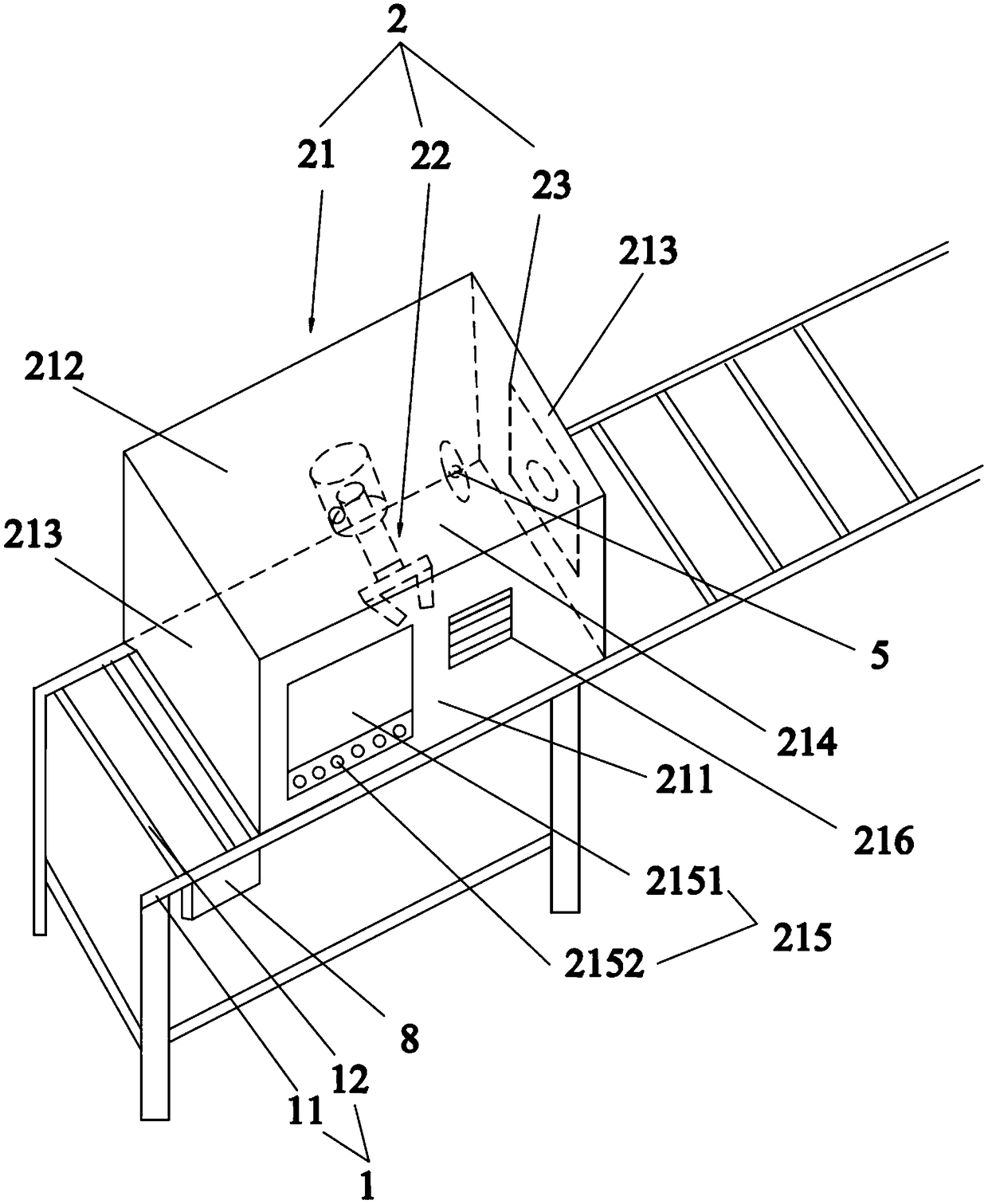

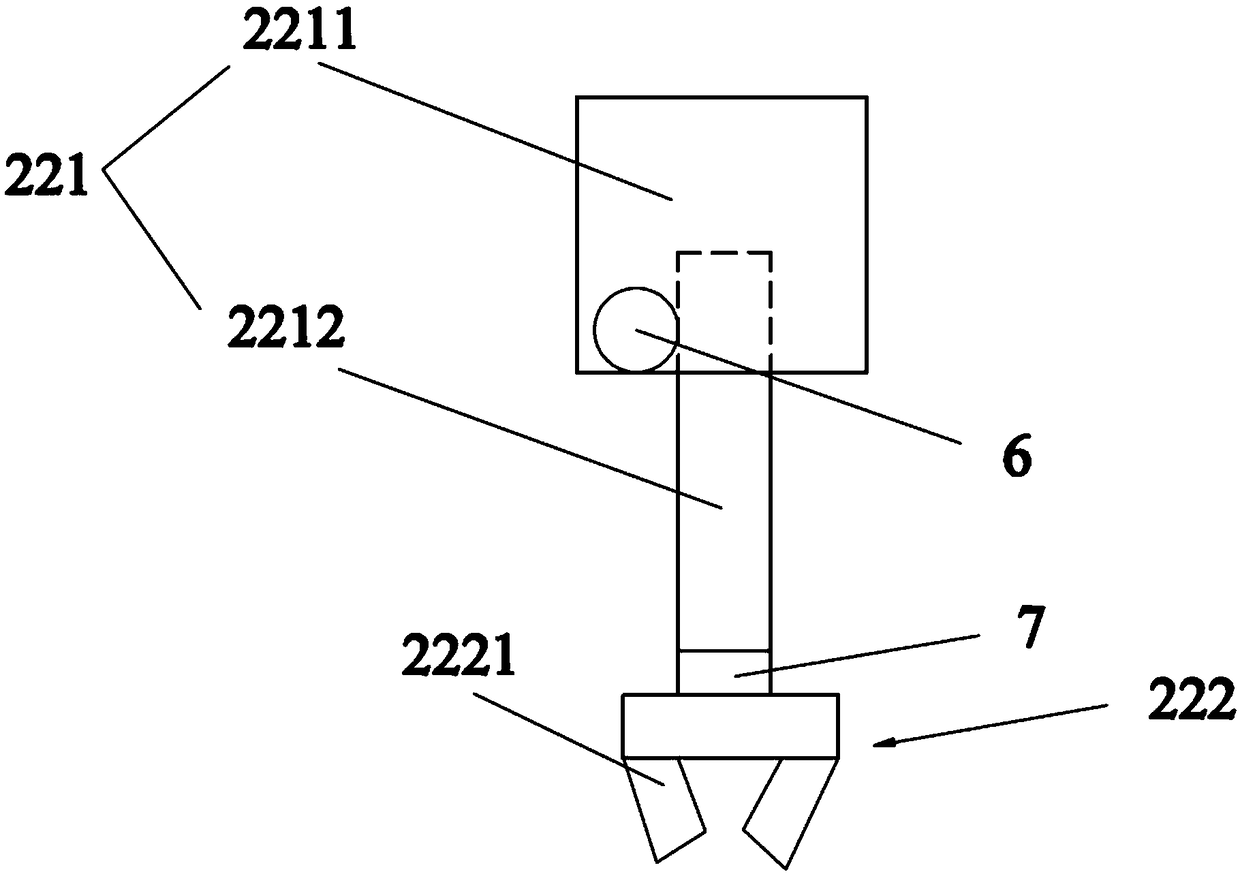

[0027] Such as Figure 1~2 As shown, a device for cleaning the battery top cover includes a delivery mechanism 1 for transporting batteries and a laser cleaning mechanism 2 for cleaning the battery top cover on the delivery mechanism 1. The laser cleaning mechanism 2 includes a cleaning box 21, and The grabbing device 22 connected to the cleaning box 21 and the positioning device 23 arranged in the cleaning box 21, the cleaning box 21 includes a front plate 211, a rear plate 212, two side plates 213 and a top plate 214, a front plate 211, a rear plate 212 1. The two side plates 213 and the top plate 214 form a frame structure, the top plate 214 is provided with a laser vibrating mirror 5 , the grabbing device 22 is fixed on the top plate 214 , and the positioning device 23 is fixed on the side plate 213 . Set up the grabbing device 22 to avoid damage to the battery caused by manual grabbing, and at the same time improve the efficiency of grabbing the battery, thereby increasin...

Embodiment 2

[0032] Such as Figure 1~2 As shown, a method of using the device of embodiment 1 to clean the top cover of the battery comprises the following steps:

[0033] 1) Transport the battery to the cleaning box 21 through the conveyor belt 12, and the main control device 215 controls the mechanical gripper 222 to grab the battery into the cleaning box 21;

[0034] 2) The main control device 215 controls the mechanical gripper 222 to rotate the battery, while the positioning device 23 photographs and positions the top cover and the edge of the aluminum case of the battery, and feeds back to the main control device 215 in real time.

[0035] 3) The main control device 215 controls the laser vibrating mirror 5 to clean the top cover and the edge of the aluminum case of the battery according to the feedback information. After the cleaning is completed, the grabbing device 22 puts the battery back into the conveying mechanism 1 for the next process.

[0036] It should also be explained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com