Highland barley red koji rice beer and brewing method thereof

A technology of highland barley red yeast rice and highland barley, applied in the direction of beer brewing, microbe-based methods, biochemical equipment and methods, etc., can solve problems such as not having health care effects, and achieve the effects of highlighting the health care effects of medicine and enriching nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

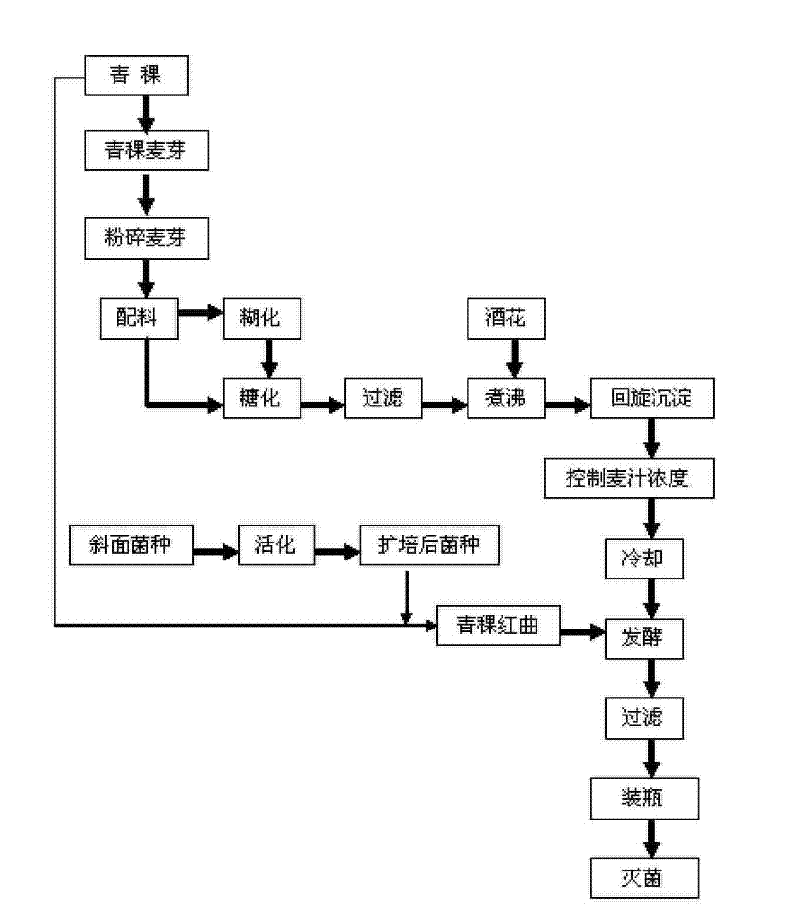

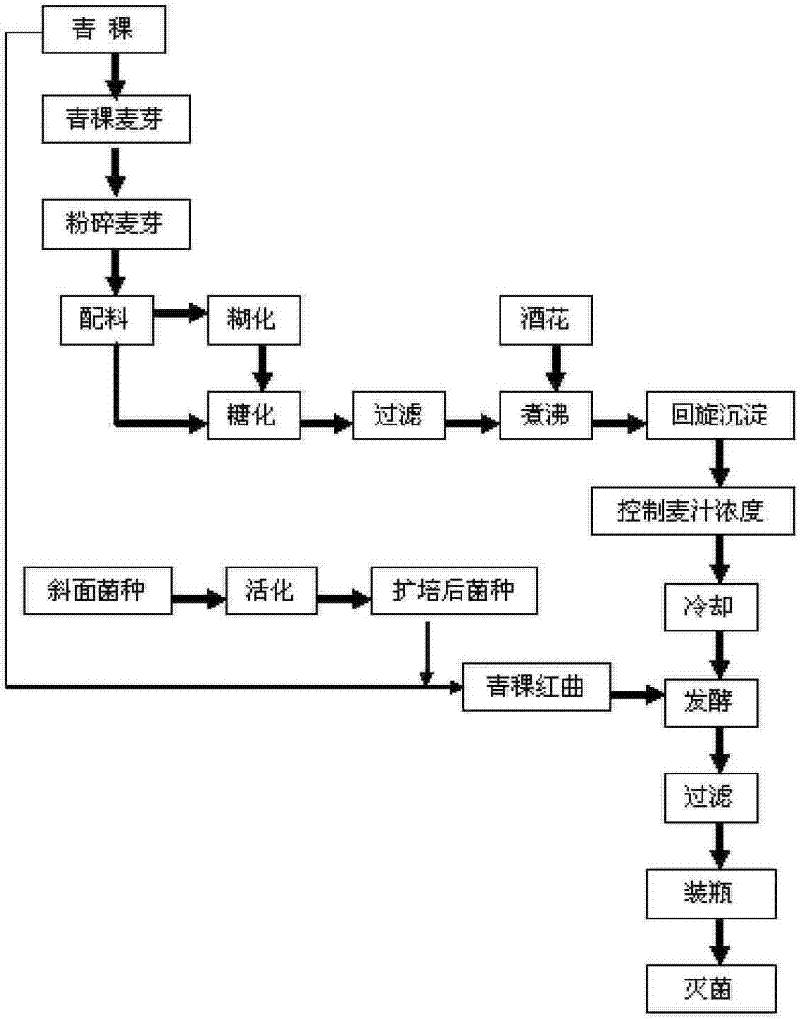

Method used

Image

Examples

Embodiment 1

[0049] The present embodiment uses highland barley as raw material to make highland barley red koji beer. Its preparation method comprises the following steps:

[0050] 1) Preparation of highland barley malt: Wash 300kg of highland barley after sorting and removing impurities, add 1500L of water to soak for 18 hours, drain, keep away from light, sprinkle water every two hours to moisten the highland barley, and wait until the malt grows to 1.5-- Dry at 75°C at 2cm;

[0051] 2) Grinding malt: Malt is crushed into malt powder by wet method in the crushing tower under light pressure. The general method of crushing malt can be used for crushing malt. It is required that the malt skin is broken but not broken. Sieve for later use, and this method can be repeated to obtain malt powder;

[0052] 3) Preparation of highland barley red yeast rice liquid:

[0053] ①Preparation of Monascus suspension: Transfer the Monascus slant strains stored in the refrigerator at 4°C to fresh Sabour...

Embodiment 2

[0067] The present embodiment uses highland barley as raw material to make highland barley red koji beer. Its preparation method comprises the following steps:

[0068] 1) Preparation of highland barley malt: Wash 300kg of highland barley after sorting and removing impurities, soak in 1200L of water for 14 hours, drain, keep away from light, sprinkle water every two hours to moisten the highland barley, and wait until the malt grows to 1.5-- Dry at 70°C at 2cm;

[0069] 2) Grinding malt: Malt is crushed into malt powder by wet method in the crushing tower under light pressure. The general method of crushing malt can be used for crushing malt. It is required that the malt skin is broken but not broken. Sieve for later use, and this method can be repeated to obtain malt powder;

[0070] 3) Preparation of highland barley red yeast rice liquid:

[0071] ①Preparation of Monascus suspension: Transfer the Monascus slant strains stored in the refrigerator at 4°C to fresh Sabouraud ...

Embodiment 3

[0085] The present embodiment uses highland barley as raw material to make highland barley red koji beer. Its preparation method comprises the following steps:

[0086] 1) Preparation of highland barley malt: Wash 300kg of highland barley after sorting and removing impurities, add 1500L of water to soak for 16 hours, drain, protect from light, sprinkle water regularly, and dry at 75°C when the malt grows to 1.5--2cm;

[0087] 2) Grinding malt: Malt is crushed into malt powder by wet method in the crushing tower under light pressure. The general method of crushing malt can be used for crushing malt. It is required that the malt skin is broken but not broken. Sieve for later use, and this method can be repeated to obtain malt powder;

[0088] 3) Preparation of highland barley red yeast rice liquid:

[0089] ①Preparation of Monascus suspension: Transfer the Monascus slant strains stored in the refrigerator at 4°C to fresh Sabouraud agar modified medium to activate for 3-5 times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com