Method for embedding and fixing horizontal grout stop belt

A grouting belt, horizontal technology, applied in water conservancy projects, marine engineering, construction and other directions, to achieve the effect of easy operation, ensure the quality of grouting, and reduce the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

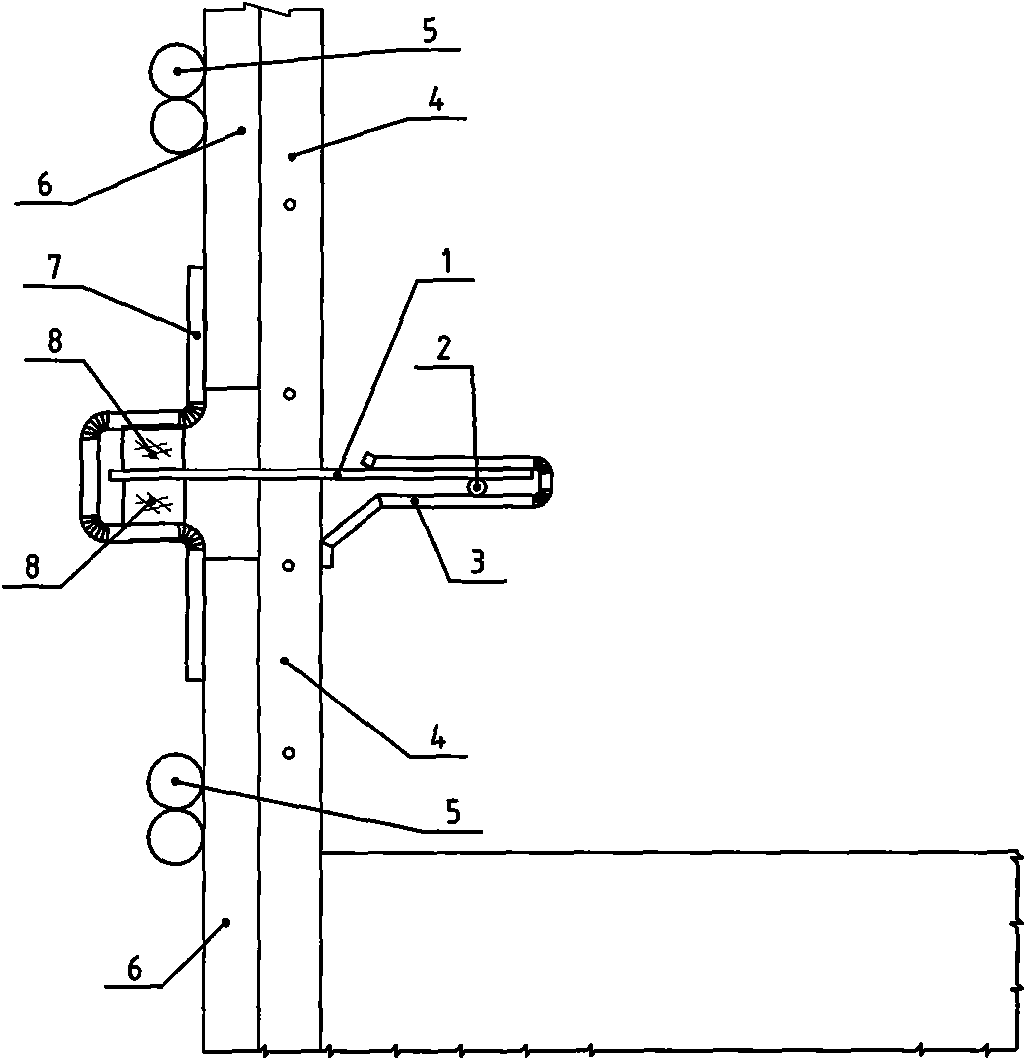

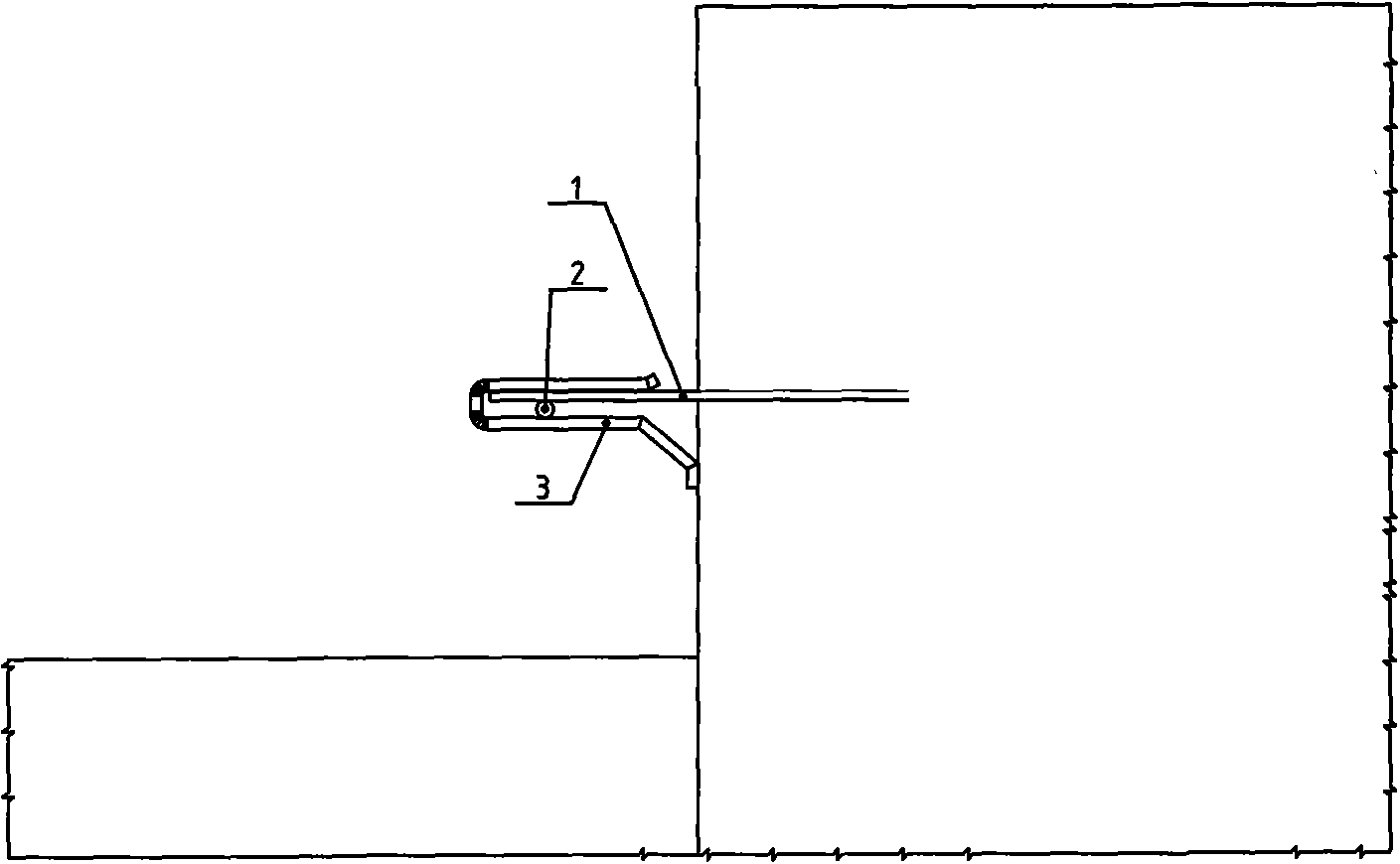

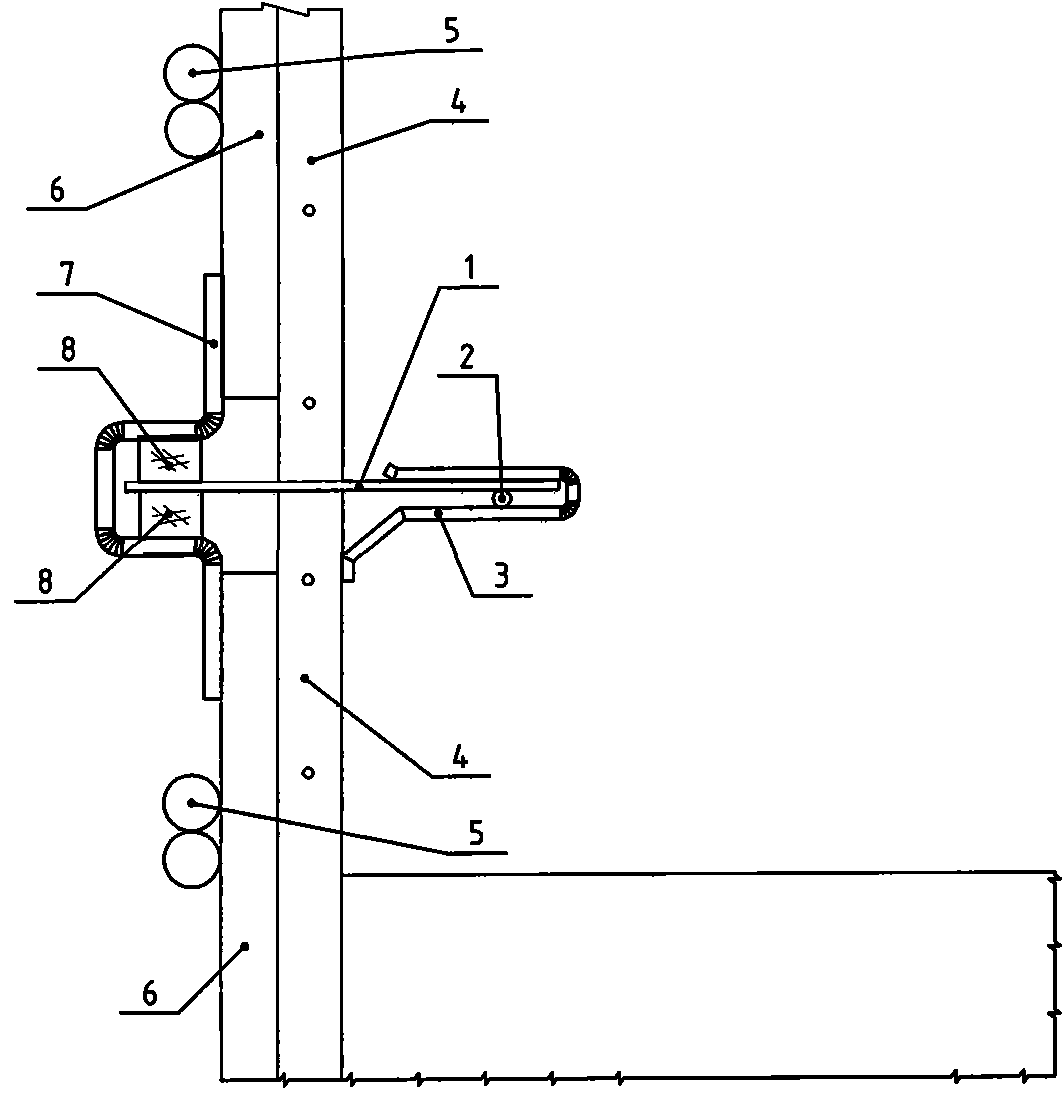

[0022] Such as figure 1 As shown, a method of burying a fixed horizontal grout stop includes the following steps:

[0023] 1) The steps of making the ribs 3 and the Ω-shaped enclosure 7,

[0024] According to the size of the horizontal slurry stop 1, make " ”-shaped clamping bar 3, making Ω-shaped enclosure 7 and welding its two ends with template vertical enclosure 6; ensuring that clamping bar 3 can clamp one end of the horizontal grout stop; In addition to being flat and firmly installed in the groove, it must also have a certain rigidity, which can meet the requirements for fixing the formwork at one place of the horizontal grout stop belt;

[0025] 2) Steps for installing the horizontal grout stop 1, template 4 and Ω-shaped enclosure 7,

[0026] According to the design and construction process requirements, first install the formwork 4 at the bottom of the horizontal grout stop 1 on the side of the post-casting block, and then install the horizontal grout stop 1, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com