Electric heating warming and wetting apparatus without medium

A technology of heating and humidification without medium, which is applied in electric heating system, air humidification system, household heating, etc. It can solve the problems that the heating system cannot be controlled by individual households and rooms, the service life is short, waste of fuel resources and electricity resources, etc. Achieve the effect of saving auxiliary mechanical and electrical equipment resources, saving economic subsidies, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

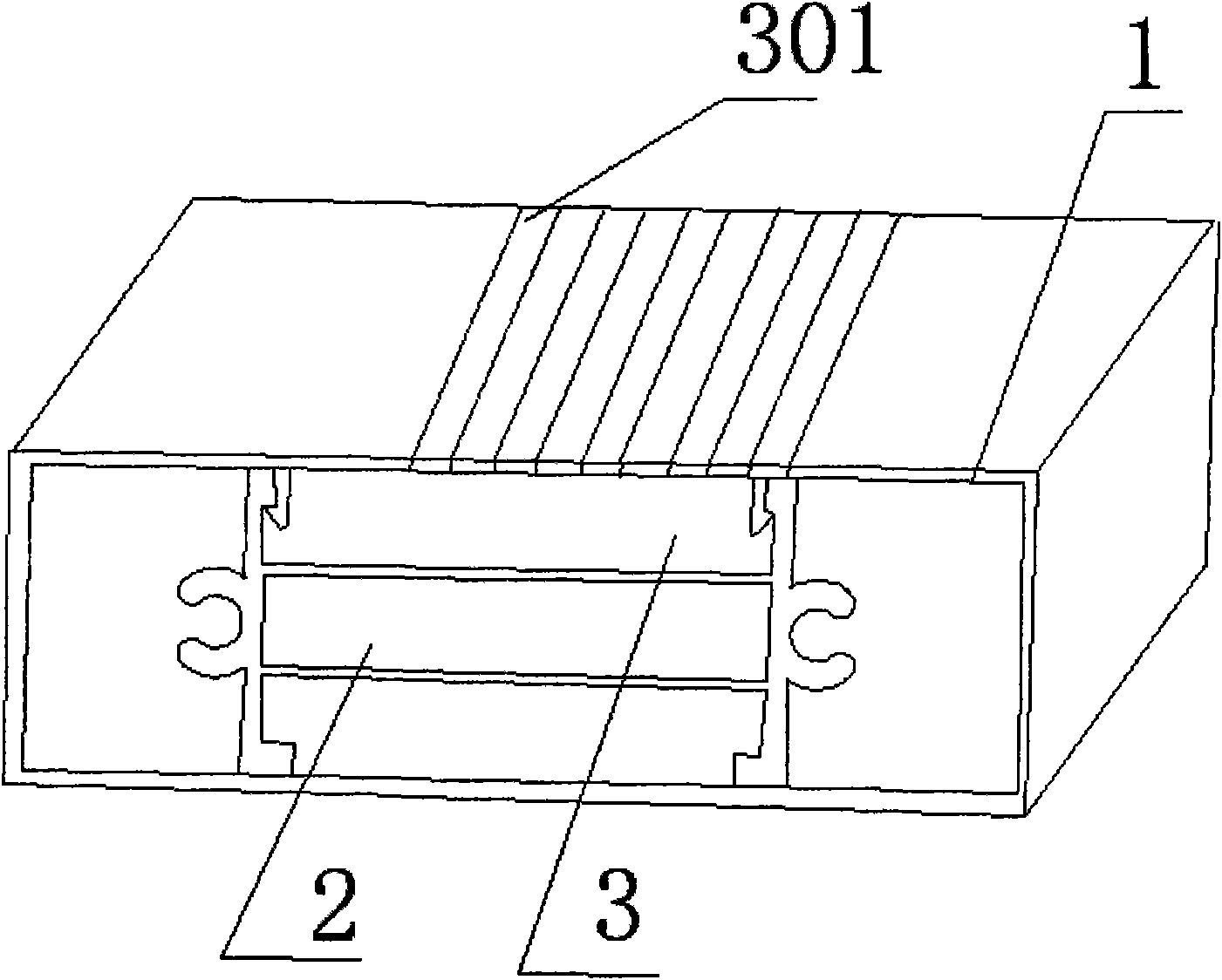

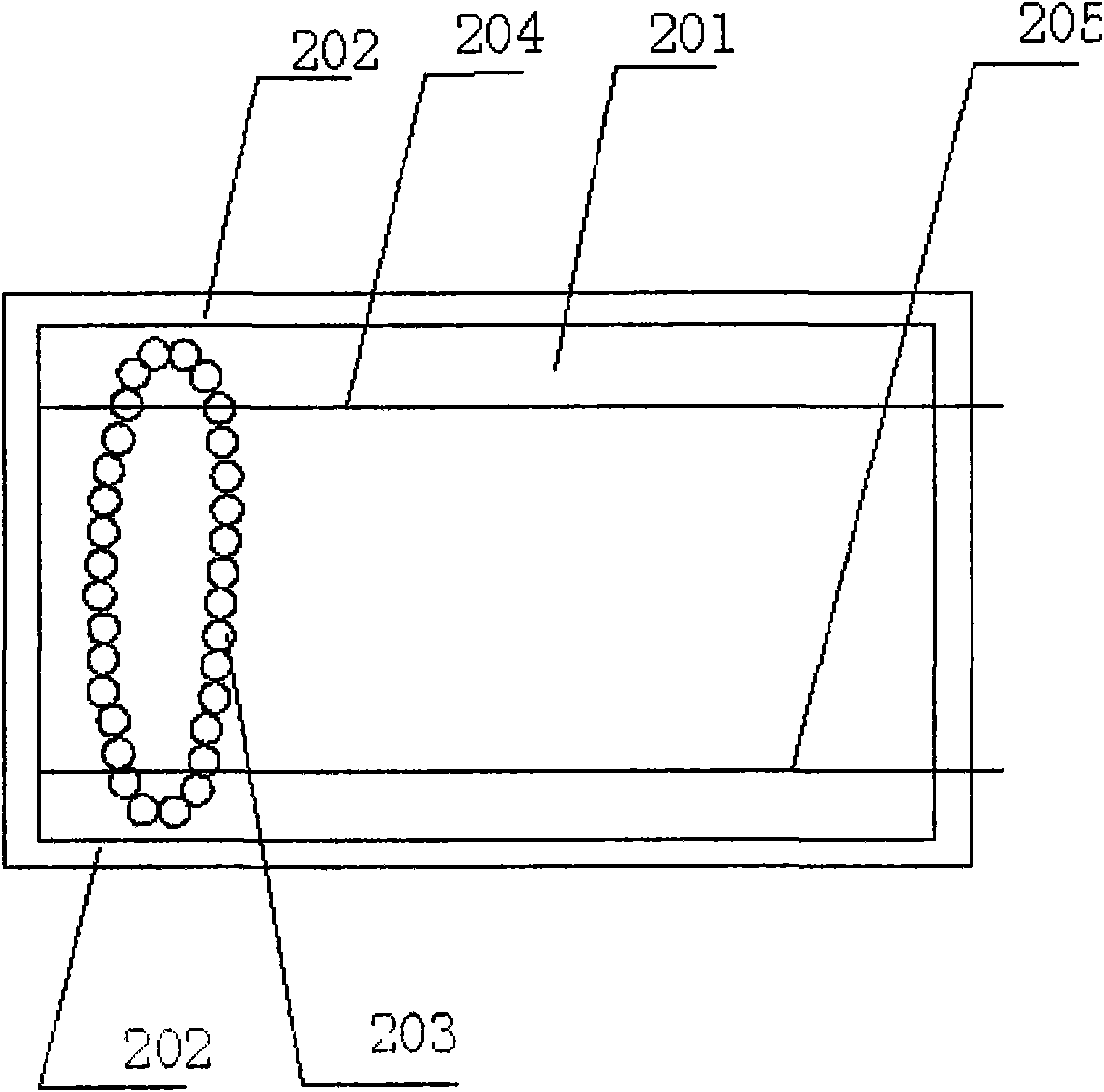

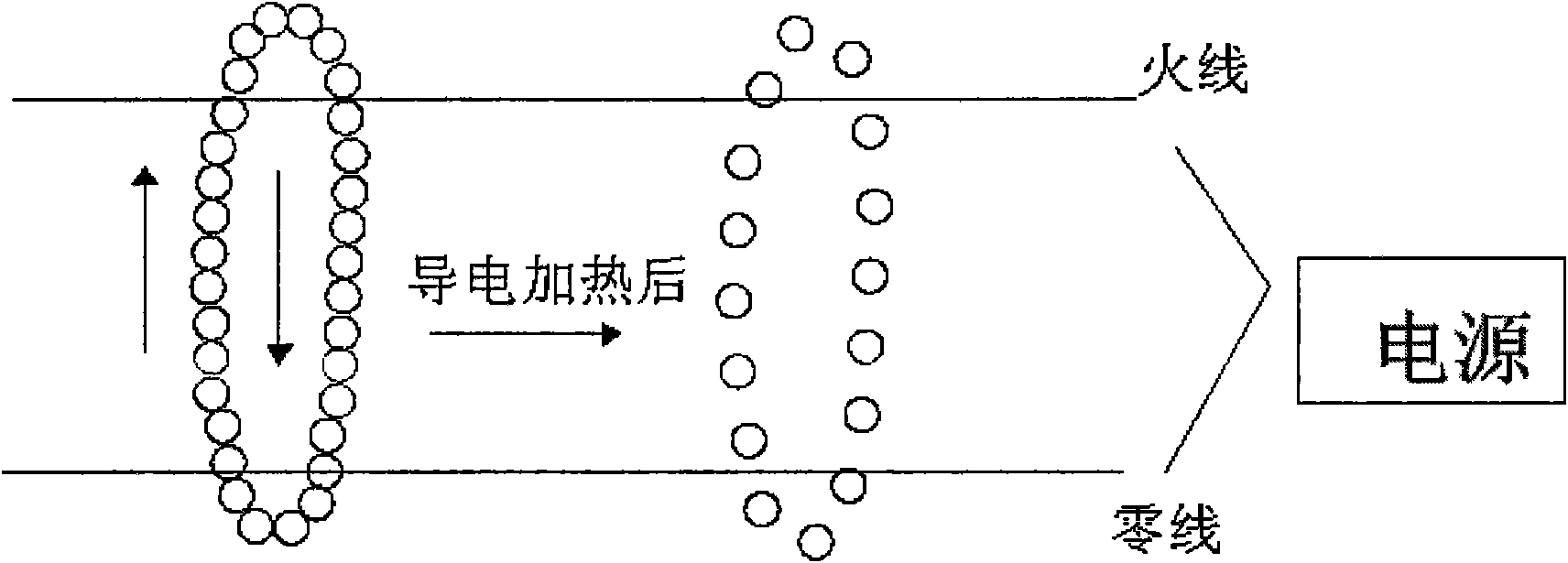

[0036] Embodiment 1 provides a medium-less electric heating and humidifying device. see figure 1 , figure 1 The schematic diagram of the structure of the medium-less electric heating and humidifying device provided for this embodiment, as shown in figure 1 As shown, the device includes a cavity 1 , a main body 2 and a humidifying layer 3 , the main body 2 is a heating part, and the main body 2 and the humidifying layer 3 are arranged in the cavity 1 . like figure 2 As shown, the main part 2 includes a heating layer 201 and an insulating layer 202. The cavity 1 is made of a heat-conducting material (such as an aluminum alloy profile), and the heating layer 201 is filled with a semicond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com