Octenyl succinate starch with colon targeting controlled release function and preparation method thereof

A technology of octenyl succinate and octenyl succinic anhydride is applied in the field of natural polymer materials in medicine to achieve the effects of improving colon targeting, increasing added value and good colon targeting controlled release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

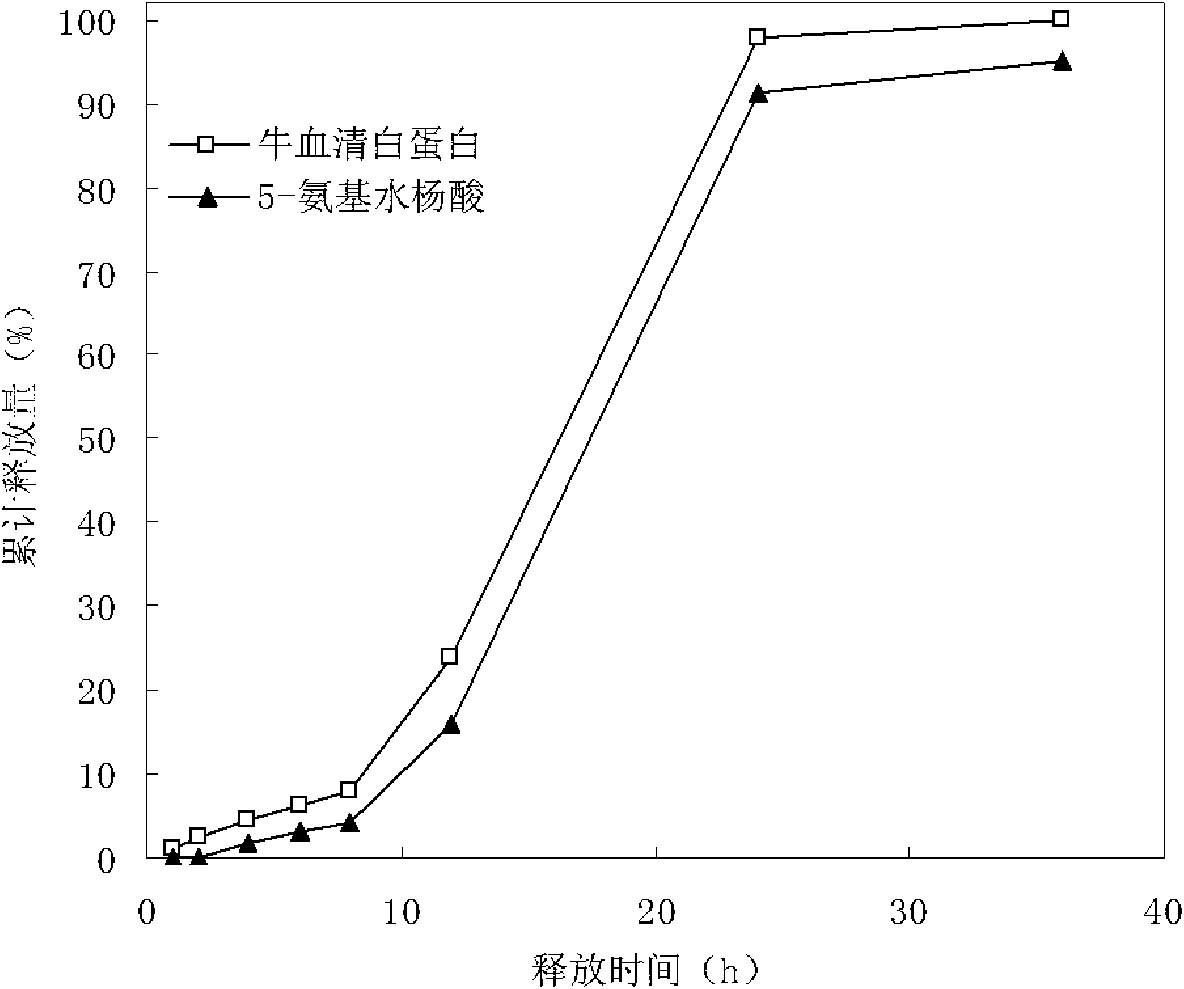

Image

Examples

Embodiment 1

[0032] (1) Weigh 10 g of starch (dry basis), the moisture content of starch is 5%, add 50 mL of organic activator pyridine and mix it in the reaction system to form starch milk with a mass percentage concentration of 20% based on starch dry basis;

[0033] (2) Under the condition of stirring, pass nitrogen gas under the liquid surface for 5 minutes to exhaust the air; control the temperature of the reaction system at 80°C, and activate for 1 hour;

[0034] (3) Control the temperature of the reaction system at 80°C, add 25 mL of octenyl succinic anhydride dropwise; react for 1 h;

[0035] (4) cooling, washing with water and suction filtration three times, washing and suction filtration twice with 70% ethanol by volume, drying in an oven at 40°C, pulverizing, and passing through a 100-mesh sieve to obtain the finished product of octenyl succinate starch.

[0036] The degree of substitution (DS) of the octenyl succinate starch prepared in this example was 0.54, and the content of...

Embodiment 2

[0038] (1) Weigh 10 g of starch (dry basis), the moisture content of starch is 3%, add 50 mL of organic activator dimethyl sulfoxide and mix in the reaction system to form starch milk with a mass percentage concentration of 20% based on starch dry basis;

[0039] (2) Under the condition of stirring, pass nitrogen gas under the liquid surface for 5 minutes to exhaust the air; control the temperature of the reaction system at 85°C, and heat and activate for 0.5h;

[0040] (3) Control the temperature of the reaction system at 100°C, add 30 mL of octenyl succinic anhydride dropwise; react for 5 hours;

[0041] (4) cooling, washing with water and suction filtration three times, washing and suction filtration with 70% ethanol twice by volume percent concentration, oven drying at 40° C., pulverizing, and passing through a 100-mesh sieve to obtain the finished product of octenyl succinate starch.

[0042] The degree of substitution (DS) of the octenyl succinate starch prepared in this...

Embodiment 3

[0044] (1) Weigh 10 g of starch (dry basis), the moisture content of the starch is 2%, add 100 mL of organic activator dimethyl sulfoxide and mix it in the reaction system to form a starch milk with a mass percentage concentration of 10% based on the dry basis of starch;

[0045] (2) Under the condition of stirring, pass nitrogen gas under the liquid surface for 5 minutes to exhaust the air; control the temperature of the reaction system at 95°C, and heat and activate for 3 hours;

[0046] (3) Control the temperature of the reaction system at 110°C, add 37 mL of octenyl succinic anhydride dropwise, and react for 1.5 h;

[0047] (4) cooling, washing with water and suction filtration three times, washing and suction filtration with 70% ethanol twice by volume percent concentration, oven drying at 40° C., pulverizing, and passing through a 100-mesh sieve to obtain the finished product of octenyl succinate starch.

[0048] The degree of substitution (DS) of the octenyl succinate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap