Method for testing preload of engine connecting rod bolt and special tool thereof

A technology of bolt pre-tightening force and engine connecting rod, which is applied in the direction of measuring torque/torsion force, measuring device, force/torque/work measuring instrument during tightening, etc. , The strain gauge requirements are very high, affecting the normal operation of the friction pair, etc., to achieve the effect of easy operation, low difficulty, and easy lead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

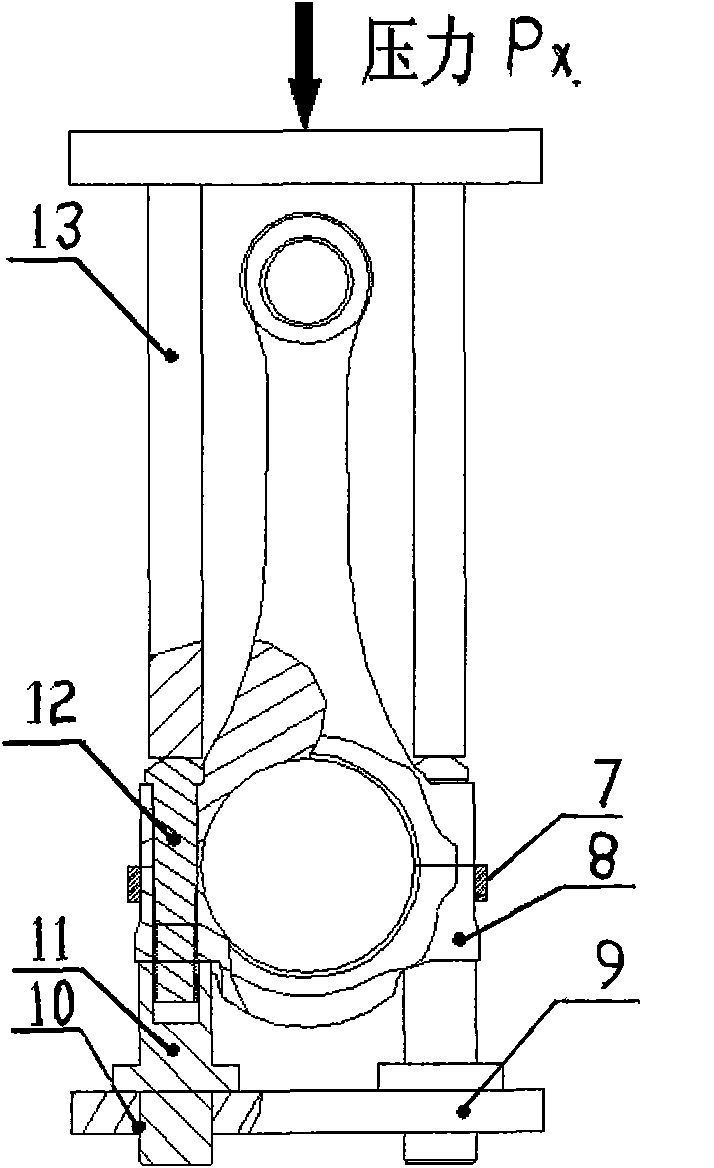

[0032] Using the method of the invention to test the pretightening force of the engine connecting rod bolts includes two testing processes: the first process is a torque test; the second process is a pressure test.

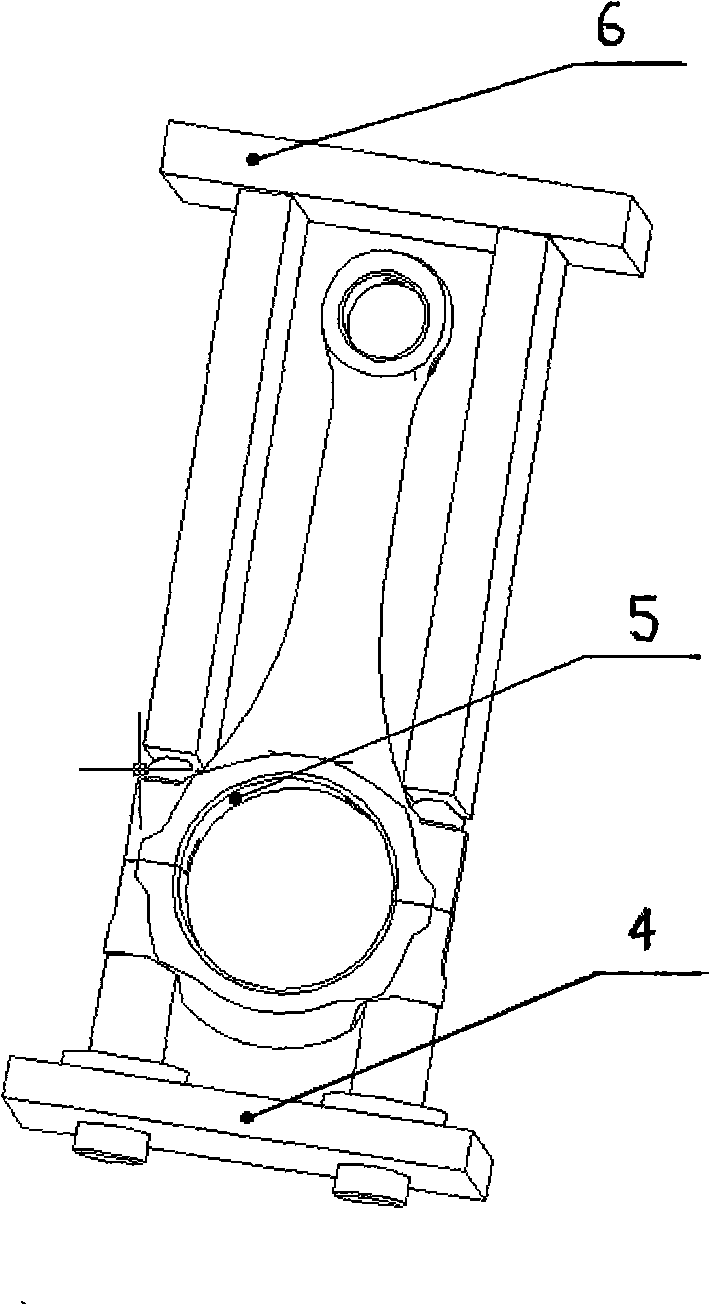

[0033] First step: torque test, such as figure 1 As shown, the process includes:

[0034] Step 1: Paste strain gauges on the outer side of the connecting rod cover, and there is a strain gauge 7 on the intake side and exhaust side respectively.

[0035] Step 2: The strain gauge 7 is connected to an external strain measuring device.

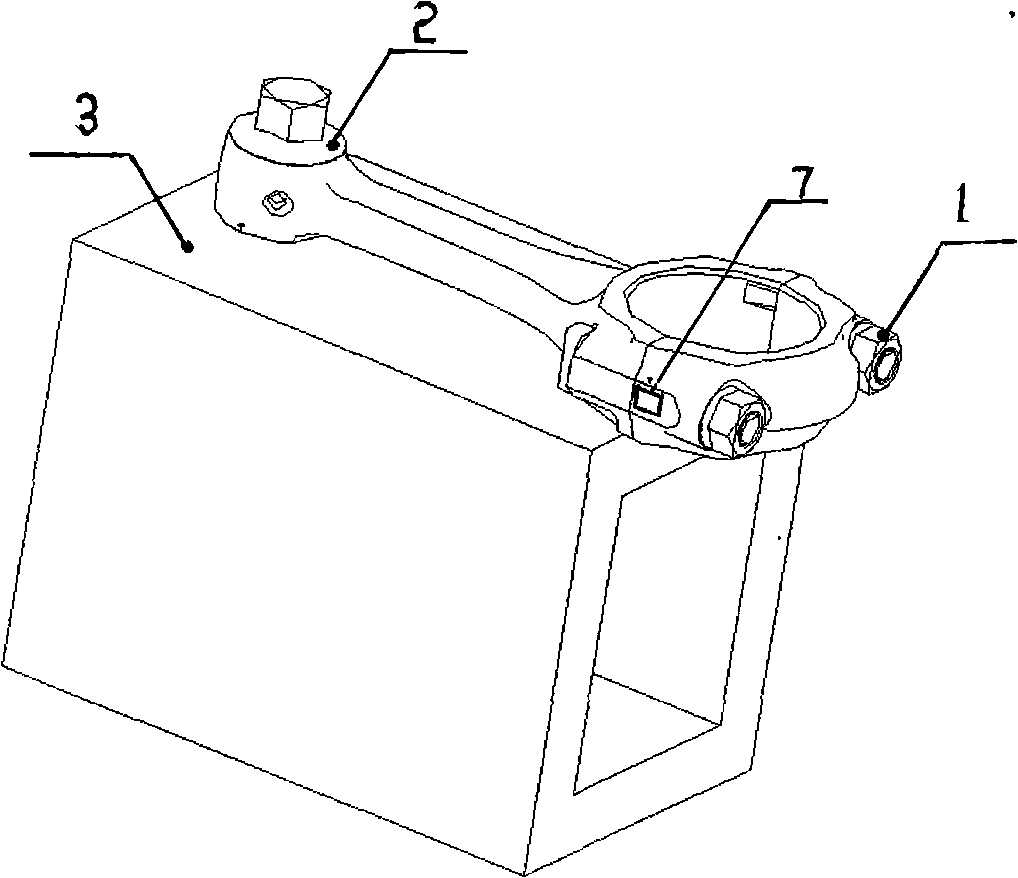

[0036] Step 3: Place the connecting rod horizontally on the support block 3, and fix the small head 2 of the connecting rod with the support block with bolts.

[0037] Step 4: Use a torque wrench to tighten the connecting rod bolts and nuts 1 according to the assembly process requirements, and read the strain and ε of the connecting rod cover under the specified tightening torque through the strain measuring device C .

[0038] ε ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com