Sand core acceleration water discharging method of gravelly soil large-scale three-shaft test and sample pore-forming maker

A technology of triaxial test and gravel soil, which is applied in the preparation of test samples, etc., can solve the problems of lack, insufficient drainage, long test period, etc., and achieve the effect of meeting the test requirements, high hole quality and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

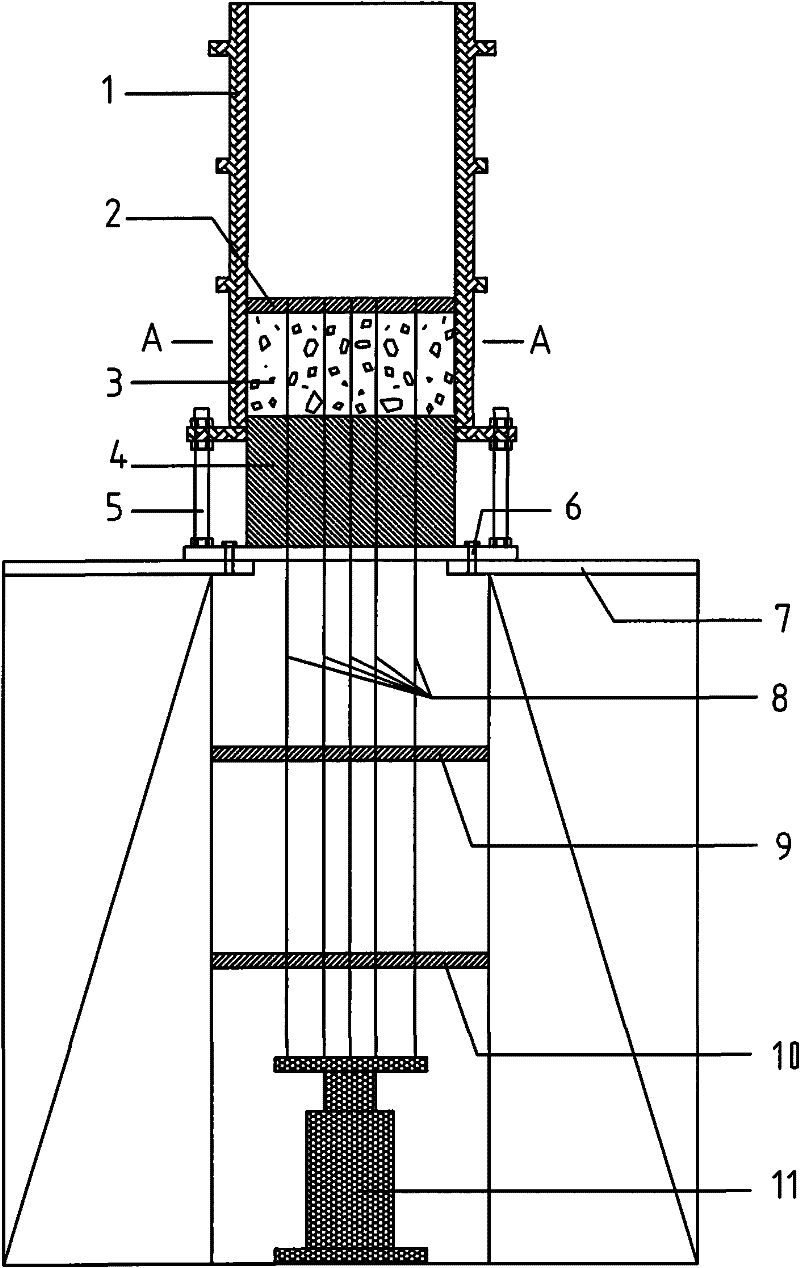

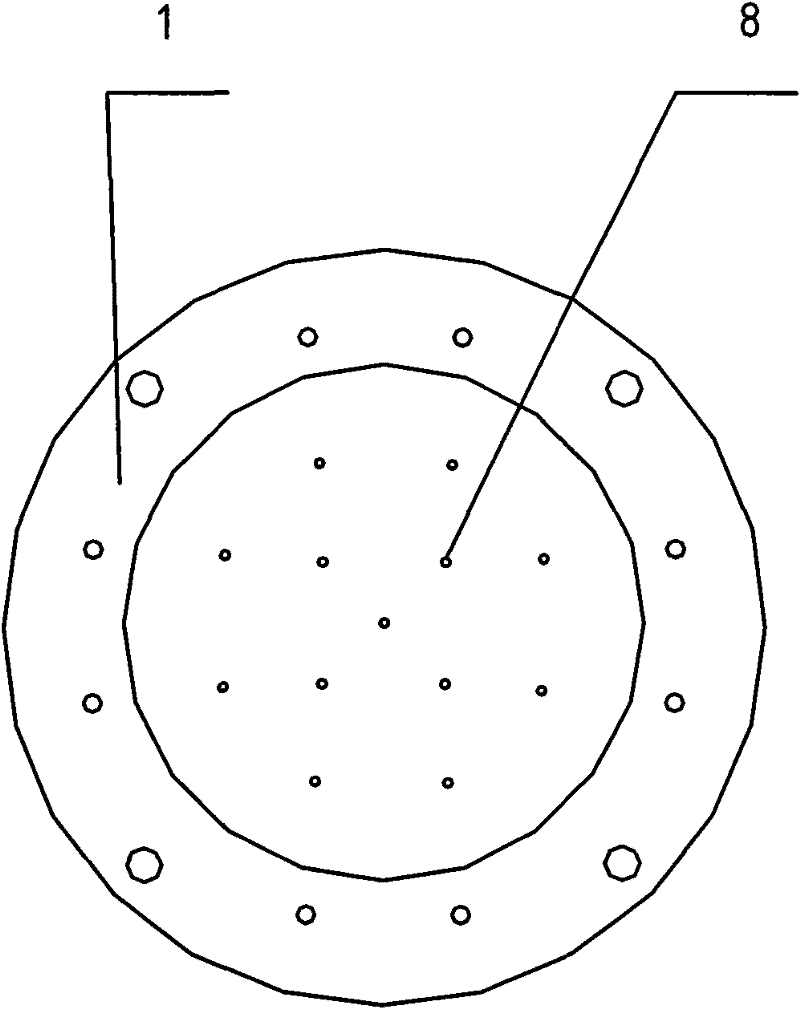

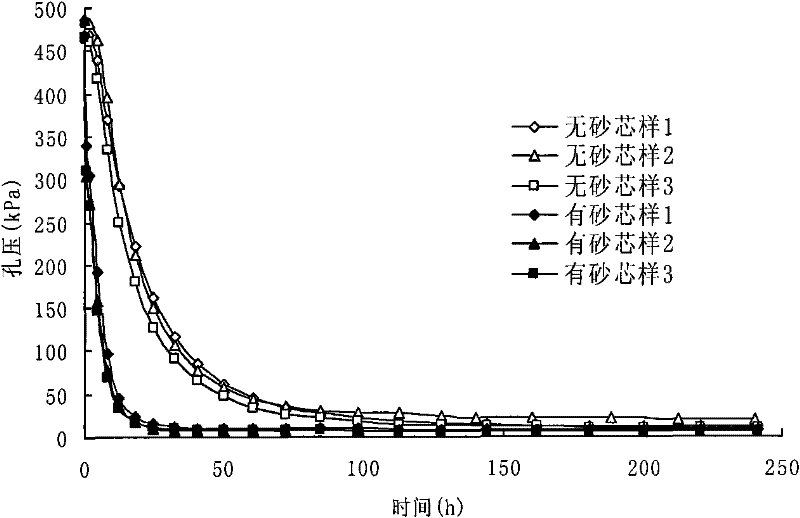

[0015] The specific implementation manners and related technical problems of the present invention will be further described in detail below in conjunction with the accompanying drawings. As mentioned above, in the prior art, due to the low permeability coefficient of gravel soil, it is very difficult to saturate large-scale samples and drain water during the test. Difficult problems have not been resolved. For this reason, the applicant has created a new test method, that is, in the large-scale gravel soil sample, holes are formed in advance along the sample axis, and sand is filled in the holes to form a sample with a sand core, which can effectively improve the test method. The saturation and drainage speed of the sample. The premise of whether this method is feasible is how much the setting of the sand core changes the strength and stress-strain characteristics of the gravel soil sample. The difference between the gravel soil and the gravel soil is the main factor determ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com