Intelligent vehicle carrier and control system and control method thereof

A control system and intelligent handling technology, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve problems such as complex working conditions, cumbersome systems, and low precision of motion control, and achieve high stability and work efficiency. The effect of clear system architecture, motion control precision and high response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

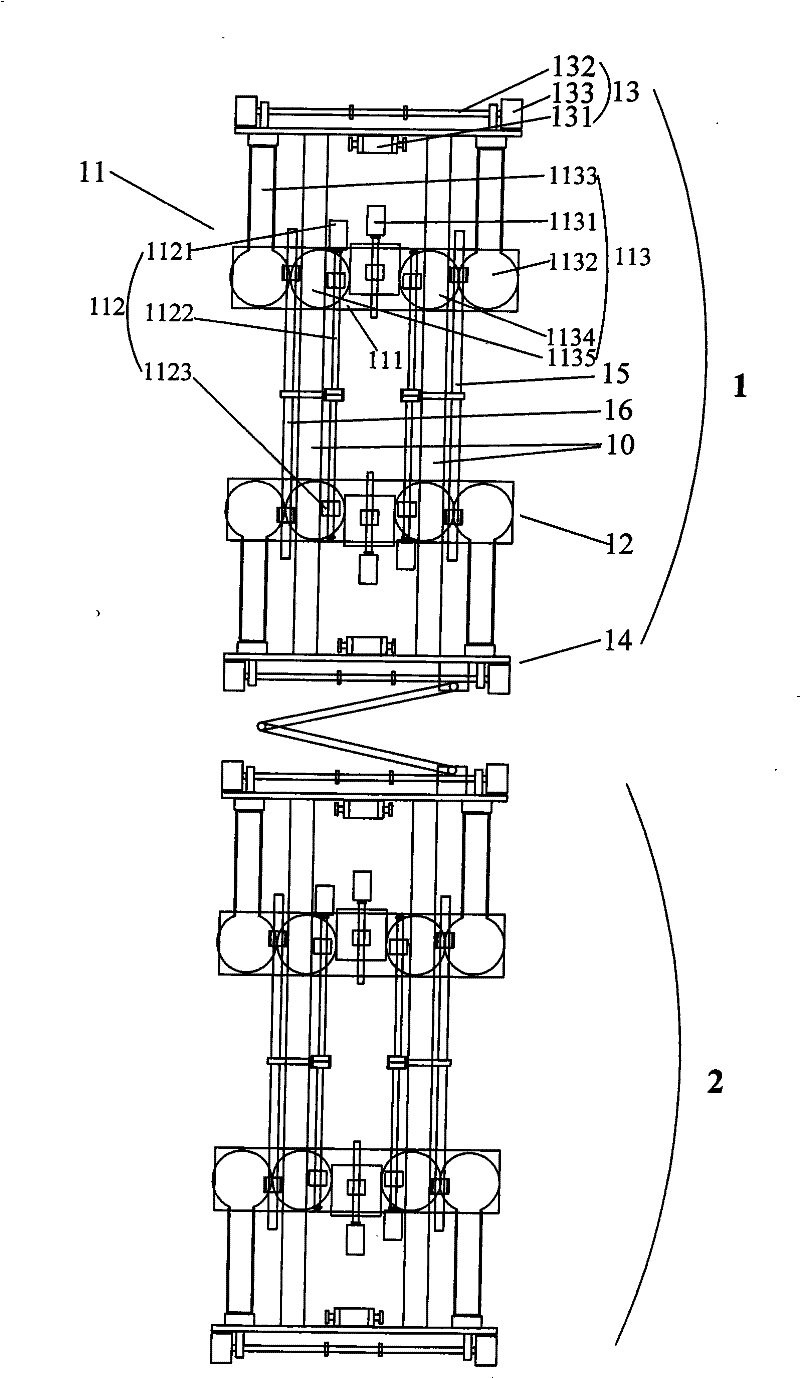

[0025] Such as figure 1 As shown, the vehicle intelligent carrier in this specific embodiment includes: two interconnected units—the first unit 1 and the second unit 2 respectively, and a control system (not shown in the figure) that controls the cooperative work of each part . The first set 1 and the second set 2 are closely attached together in the original state.

[0026] The first unit 1 includes: a first frame 10, linear guide rails 15, 16, two push plate mechanisms, respectively the first push plate mechanism 11 and a second push plate mechanism 12, and two traveling mechanisms, respectively the first walking mechanism Mechanism 13 and the second walking mechanism 14.

[0027] The first push plate mechanism 11 and the second push plate mechanism 12 are arranged on the front part and the rear part of the first unit 1, and are all connected with the first frame 10 through the linear guide rails 15, 16 which are parallel and symmetrically arranged on the left and right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com