Calibration circuit of RC filter and method

A technology for calibrating circuits and calibration methods, which is applied in the direction of electrical components, impedance networks, multi-terminal pair networks, etc., can solve problems such as low power consumption, difficulty in circuit calibration to ensure high precision, and inability to calibrate changes in capacitance and resistance values in real time, so as to improve Calibration accuracy, effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

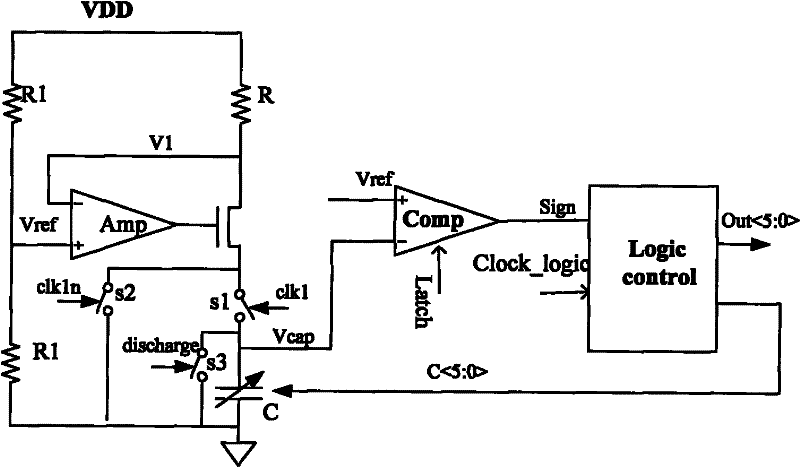

[0022] see figure 1 , The present invention discloses a calibration circuit for an RC filter, the RC filter includes a resistor R and a capacitor C, one end of the RC filter is connected to a power supply with a voltage of VDD, and the other end is grounded. The circuit includes an amplifier, a comparator, and a controller.

[0023] The output terminal of the amplifier is connected between the resistor R and the capacitor C, the first input of the amplifier is divided into a voltage of VDD / 2 (the voltage Vref=VDD / 2 of the first input of the amplifier), and the second input of the amplifier is connected to Enter one end of the resistor R (the voltage of the second input of the amplifier V 1 ≈ Vref = 1 2 VDD ). The method for the first input of the amplifier to divide the voltage into VDD / 2 can be as follows: set two resistors with the same resistance value in series, and generate a ref...

Embodiment 2

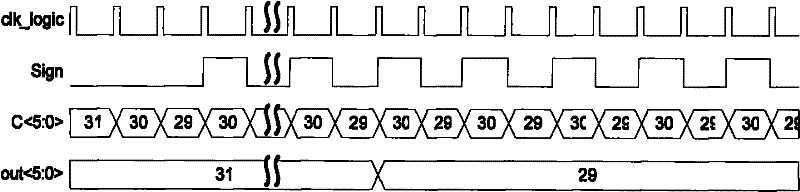

[0033] The essence of RC calibration is to ensure that the RC product of the circuit remains unchanged by adjusting R, C or both under different working environments and different manufacturing process conditions. Only C is adjusted alone in the present invention.

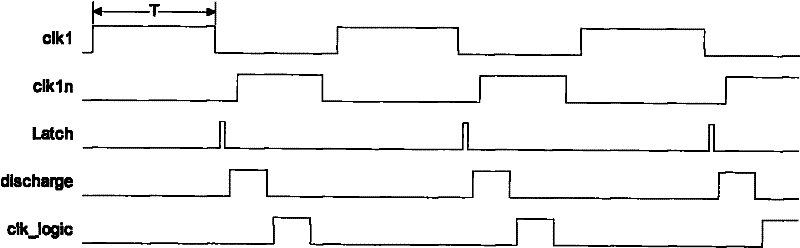

[0034] see figure 1 , the specific circuit implementation of the present invention is as figure 1 shown. Divide the voltage of the power supply through the resistor to get Vref = 1 2 VDD , Amplifier Amp is connected with buffer buffer, V 1 ≈ Vref = 1 2 VDD , Therefore, the current flowing through the resistor R is the charging current of the capacitor I ch arg e ≈ VDD 2 R . After charging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com