Overlock machine for assembling mesh-like laps with a transverse thread

A technology of pore structure and slotting machine, applied in the field of slotting machine, can solve the problems of irregular and unsightly seams, achieve the effect of small inertia, reduce positioning accuracy, and improve total output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

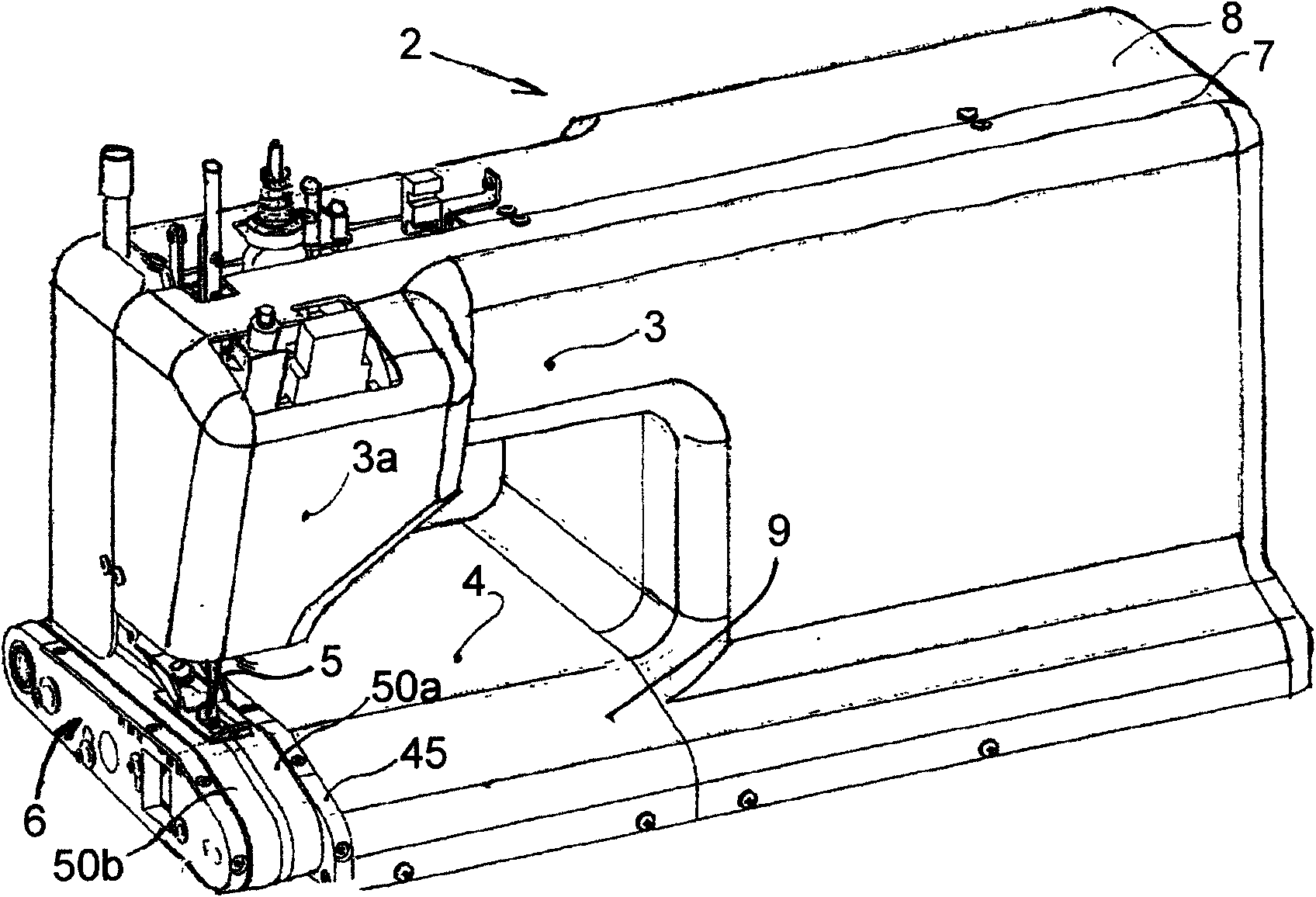

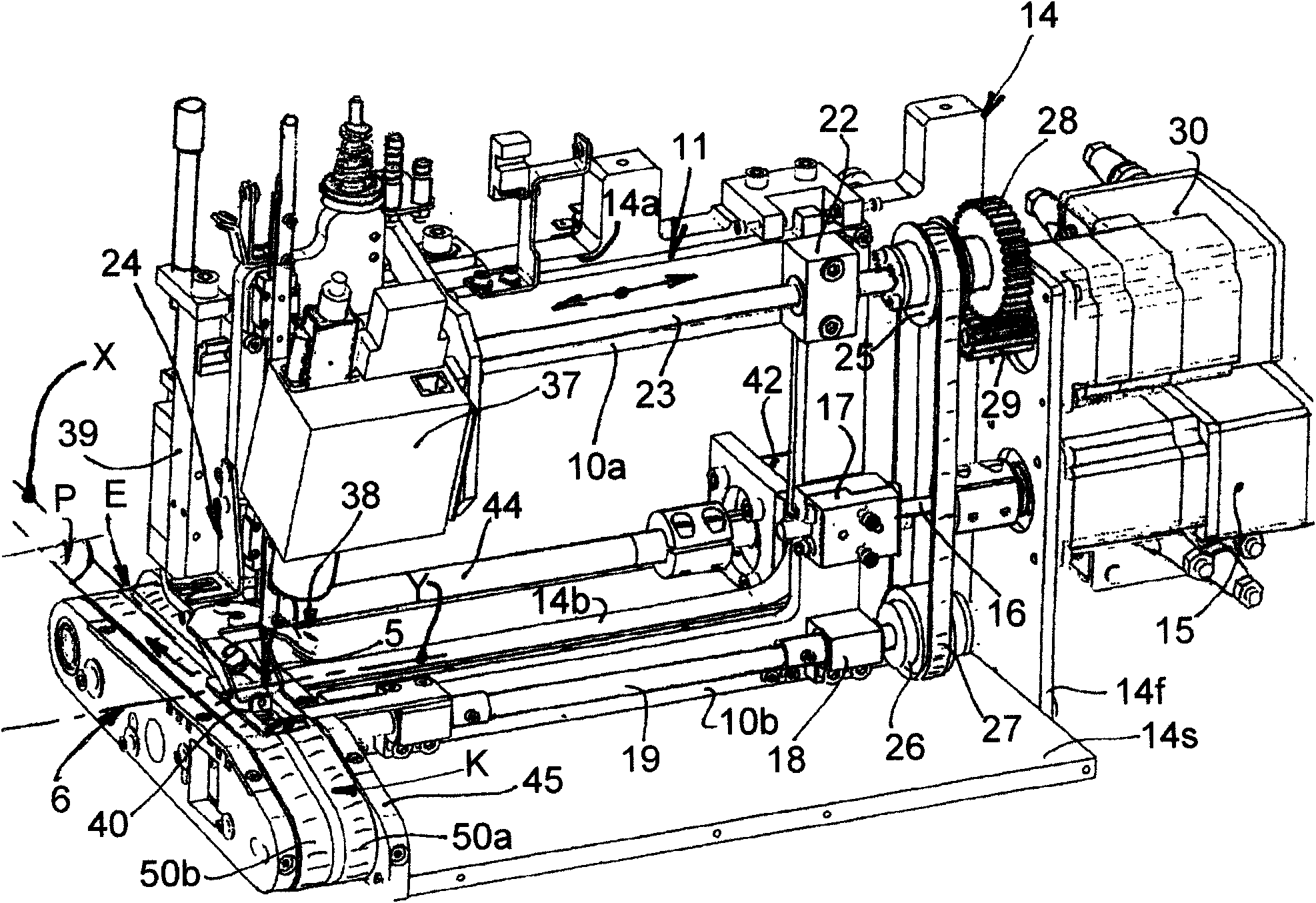

[0043] Such as figure 1 As shown, the looping machine has the general form of a sewing machine and comprises a body 2 with a swan neck 3 in the upper part and a plate 4 in the lower part. The nose 3a of this swan neck contains part of the mechanism of the needle 5 and supports the figure 2 with 3 Different devices are described. Plate 4 is extended by a housing 6 containing means for moving forward the reels N1 and N2 to be connected. The unit is protected by removable covers 7, 8 and 9, which are in figure 2 is removed.

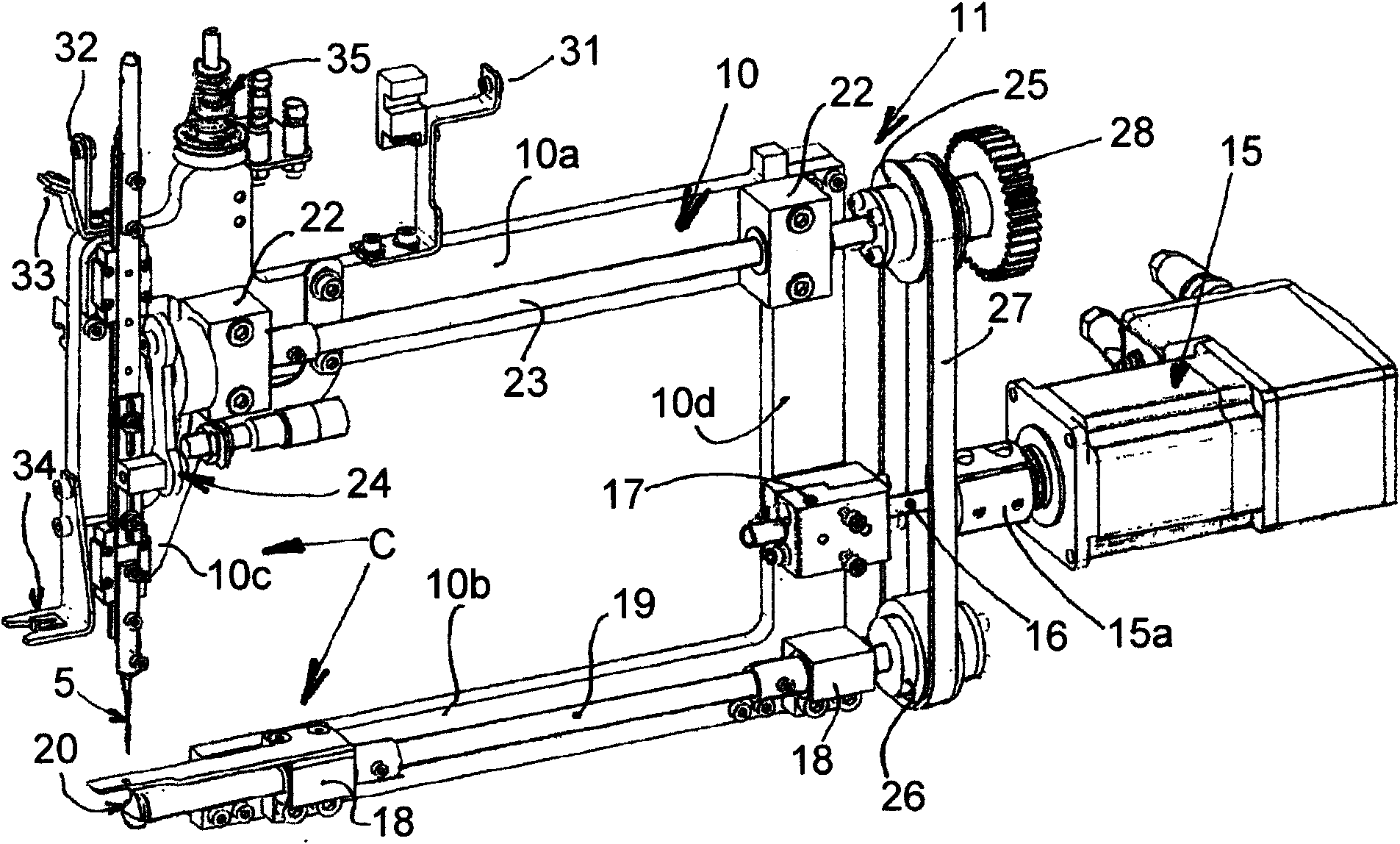

[0044] in detail figure 2 Before the different sections presented in , it is necessary to mention image 3 , which shows an embodiment of a frame 11 carrying the sewing mechanism C (ie, the needles and their hooks and their drive means).

[0045] According to the invention, this frame 11 is formed by a metal frame 10 having a flat U-shape with its upper arm 10a extending horizontally and equipped at its free end with a downwardly vertical appendage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com