Fail-safe mechanism for automatic transmission, and fail-safe valve provided in the fail-safe mechanism

An automatic transmission, fail-safe technology, used in mechanical equipment, transmission control, components with teeth, etc., can solve the increase in assembly man-hours and assembly operations complexity, increase in fail-safe valve size, and increase in production costs, etc. problems, to achieve the effect of suppressing the increase in production cost, preventing weight increase, and solving valve sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

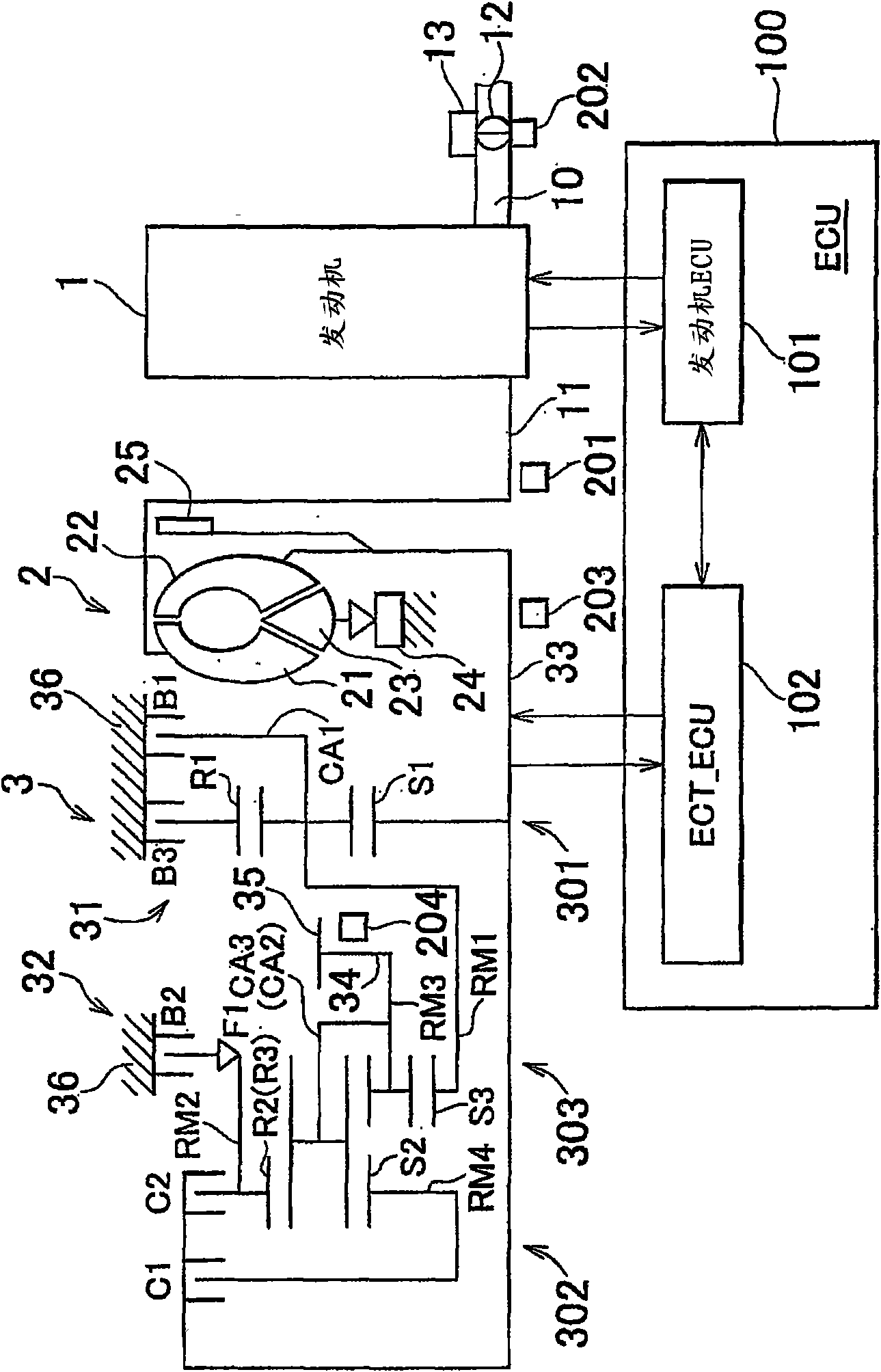

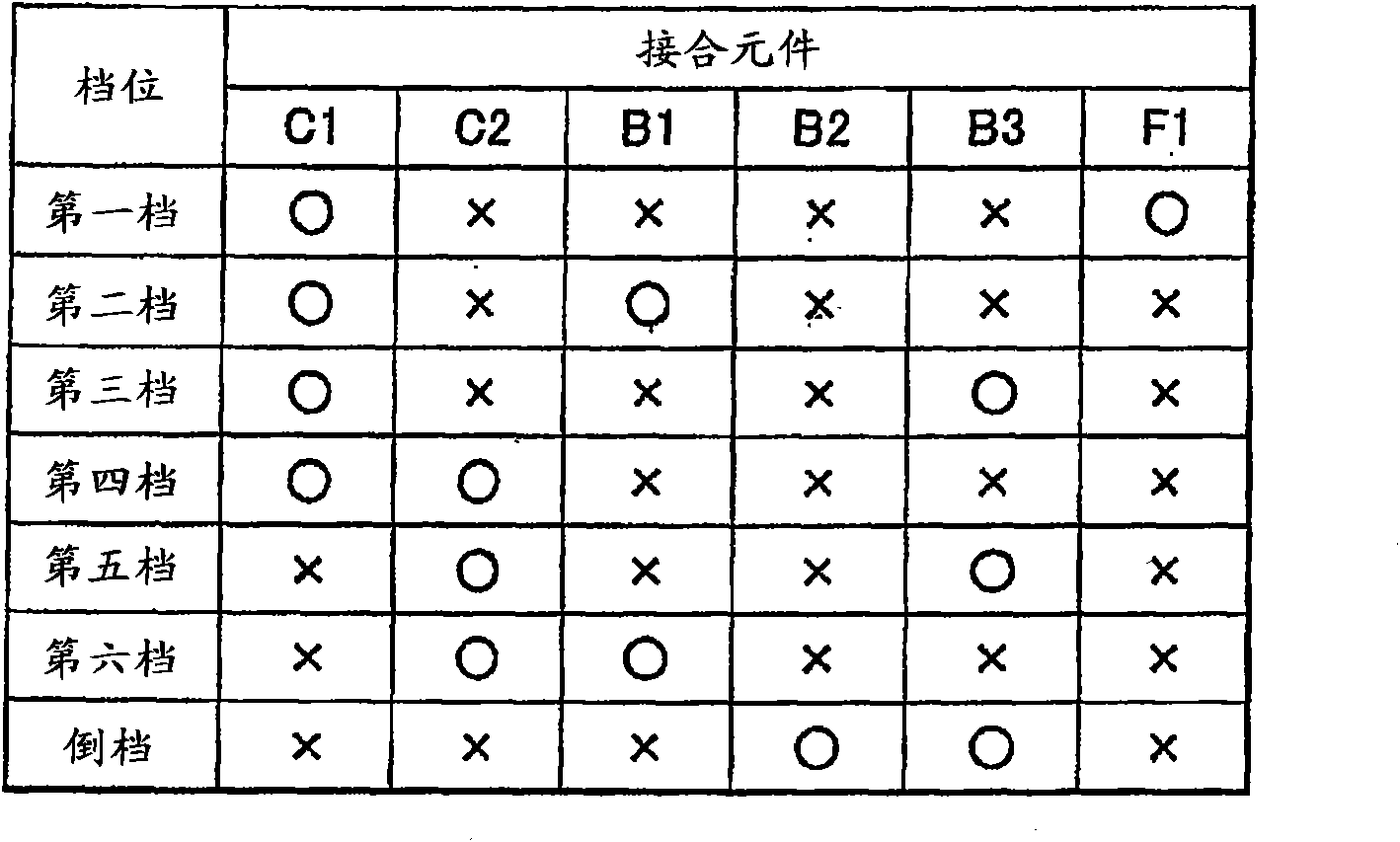

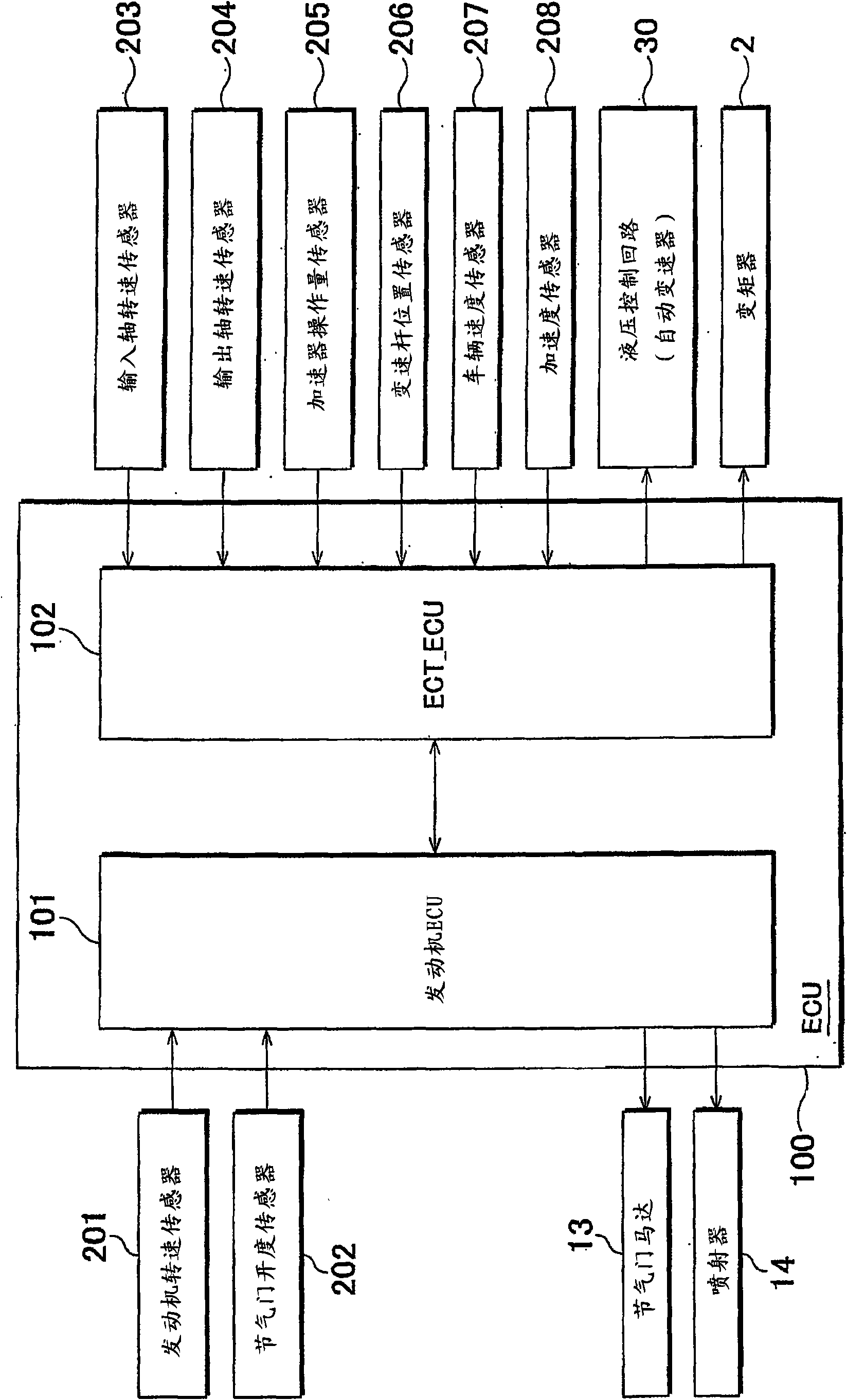

[0049] Embodiments of the present invention will be described below with reference to the drawings. As an embodiment, a case where the present invention is applied to an automatic transmission mounted in an FF (front-engine, front-wheel drive) vehicle will be described. Before describing the configuration and operation of the fail-safe valve which is a feature of the embodiment, the basic operation and the like of a power train for a vehicle and an automatic transmission of a vehicle will be described.

[0050] Such as figure 1 As shown, a vehicle Z is equipped with an engine 1 , a torque converter 2 , an automatic transmission 3 , and an ECU 100 . Each of engine 1 , torque converter 2 , automatic transmission 3 , and ECU 100 will be described below.

[0051] The engine 1 is, for example, a four-cylinder gasoline engine. A crankshaft 11 , which is an output shaft of the engine 1 , is connected to an input shaft of the torque converter 2 . The rotational speed (engine rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com