High-voltage pulse generator and high-pressure discharge lamp comprising such a generator

A technology of pulse generator and high-pressure discharge lamp, which is applied in the direction of electric light source, electrical components, lighting devices, etc., can solve the problems of rising, cannot be heated, cannot be implemented, etc., and achieve compact structure, high capacitance, and easy breakdown Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

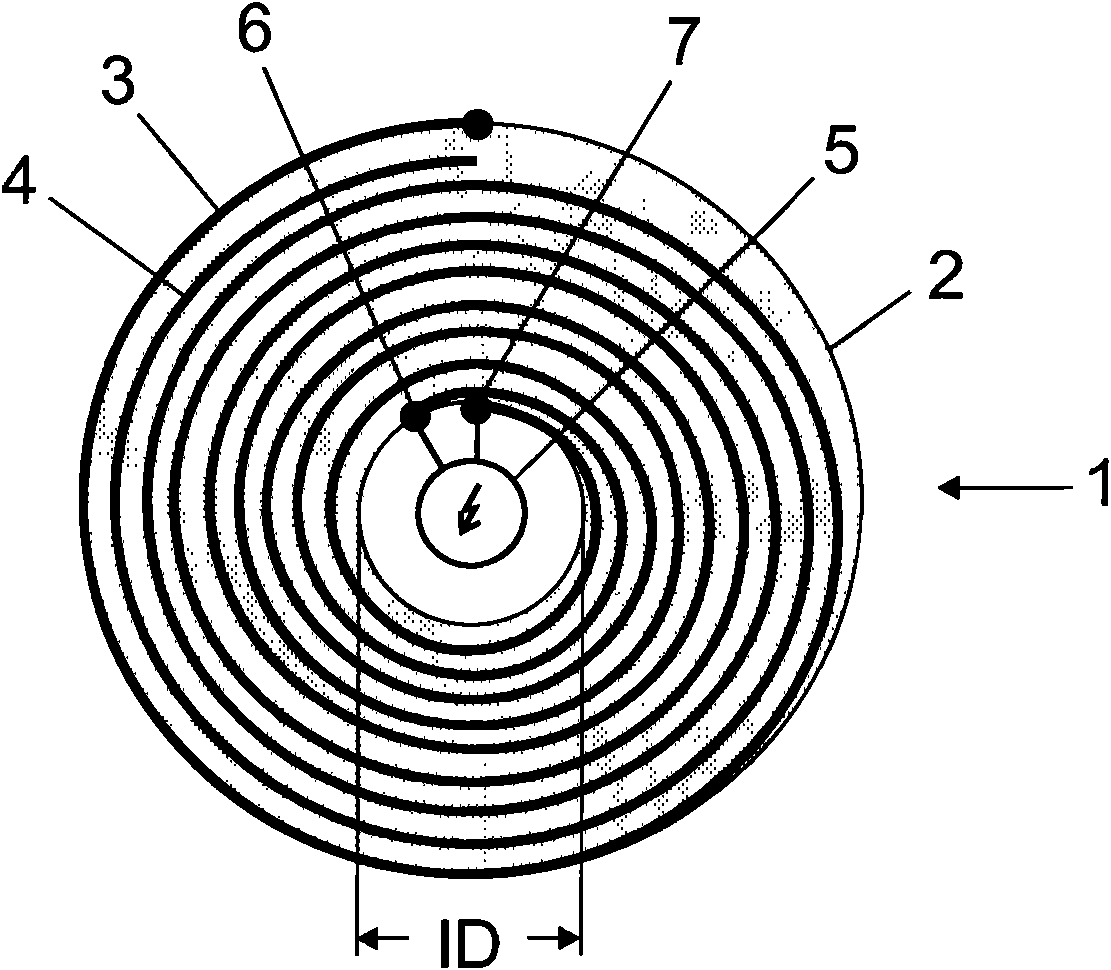

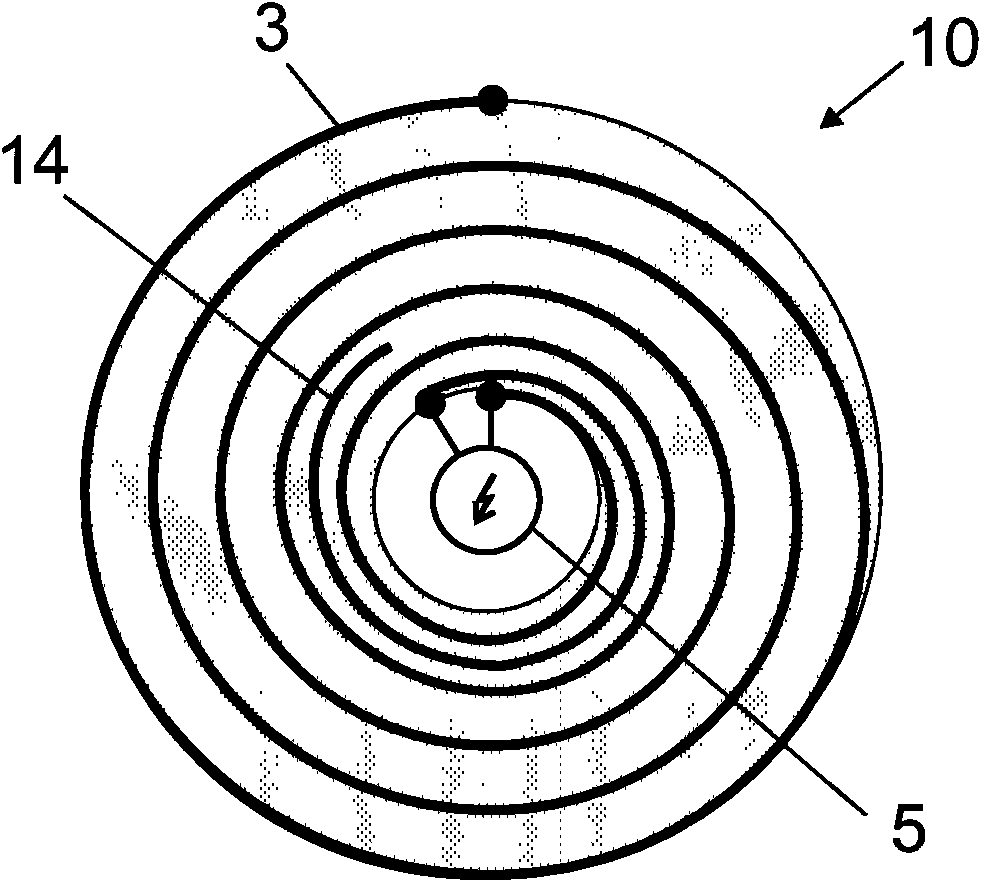

[0030] figure 1 The principle structure of the helical pulse generator 1 is shown in plan view. The helical pulse generator comprises a ceramic cylinder 2 into which two different metallic conductors 3 and 4 are wound helically as film strips. The cylinder 2 is hollow on the inside and has a given inner diameter ID. The two inner contacts 6 and 7 of the two conductors 3 and 4 lie as closely as possible parallel to each other and are connected to one another via a spark gap 5 .

[0031] Only the outer conductor of the two conductors has a further contact 8 at the outer edge of the cylinder. The other conductor terminates openly. Thus, the two conductors together form a waveguide in the dielectric medium (ceramic).

[0032] The helical pulse generator is wound from two ceramic membranes coated with metal paste or consists of two metal membranes and two ceramic membranes. An important characteristic quantity here is the number of turns n, which should preferably be in the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com