Acrylic hyperbranched resin and application thereof in mirror back paint

A technology of hyperbranched resin and acrylic acid, which is applied in the direction of coating, etc., can solve the problems of water resistance and salt spray resistance, and achieve the effect of good water resistance, fast drying speed and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation of embodiment 1 acrylic acid hyperbranched resin

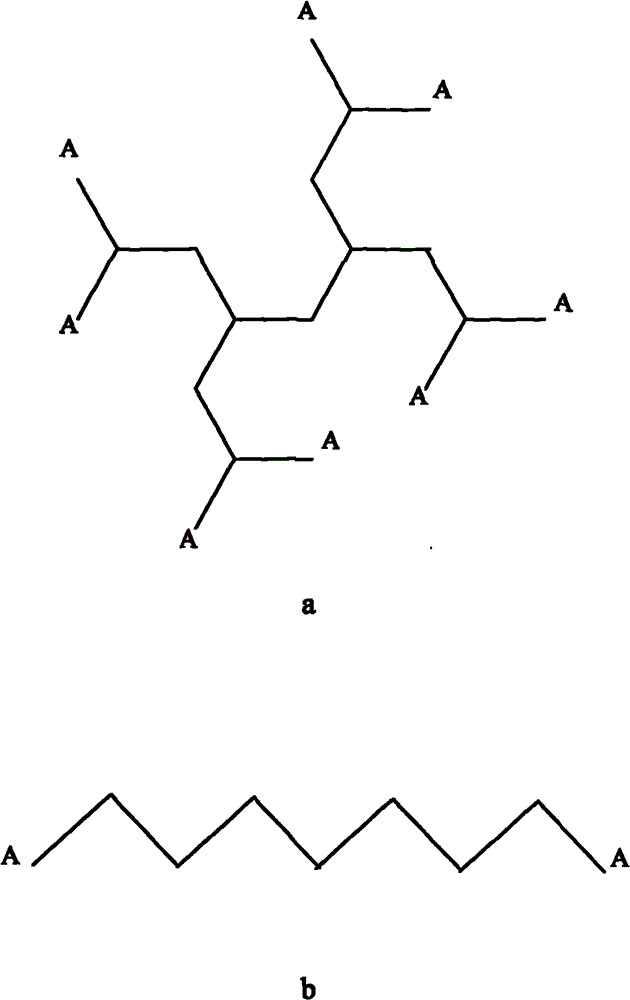

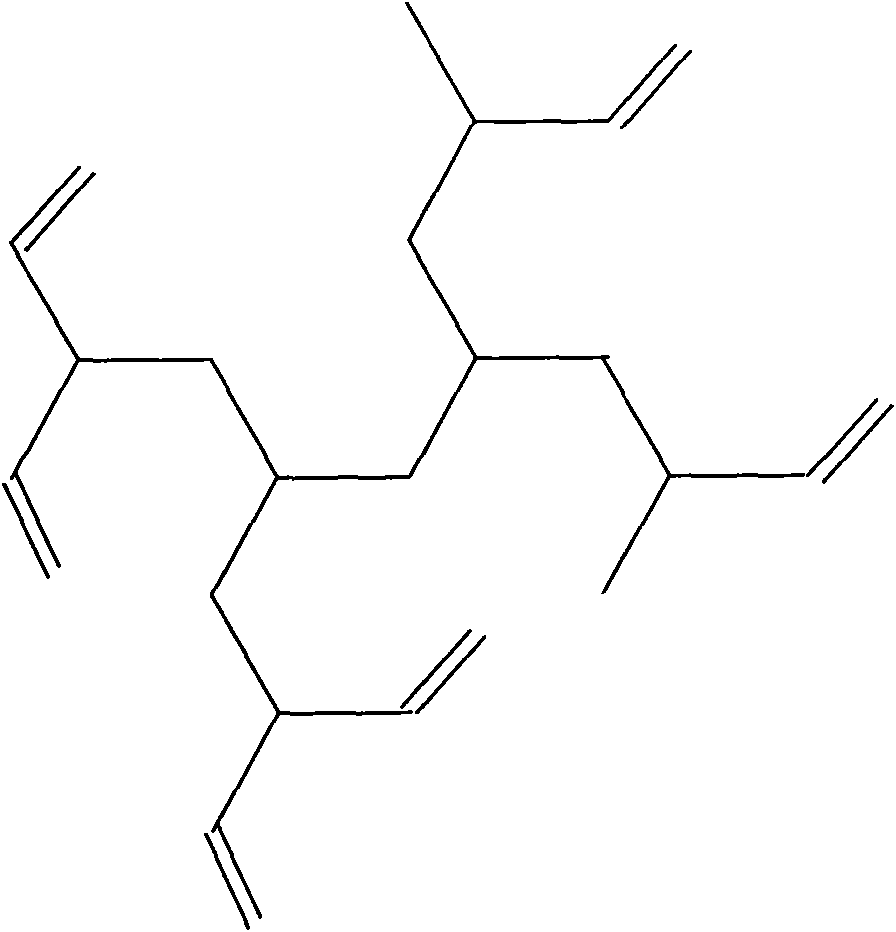

[0037] ATRP technology synthesizes acrylic acid hyperbranched resin containing a large number of active double bonds.

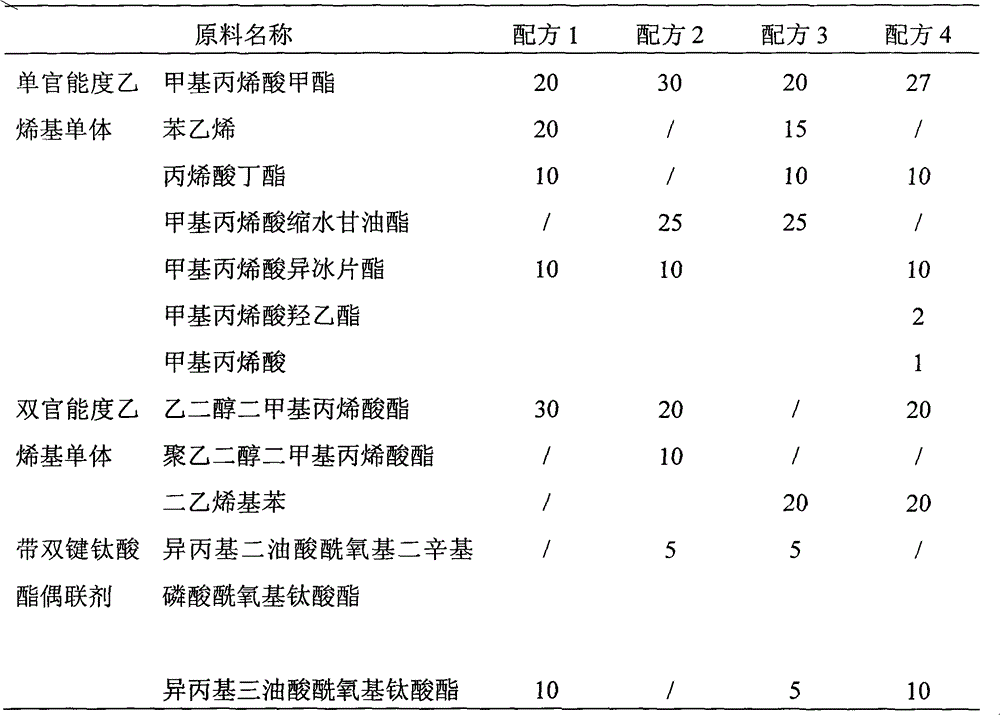

[0038] According to the composition of four kinds of acrylic acid hyperbranched resins listed in Table 1, each monomer was weighed and mixed respectively. Values in the table are parts by weight:

[0039] Table 1 Composition of four kinds of acrylic acid hyperbranched resins

[0040]

[0041] There are many possible formulations, and the above formulations are only four references, and the present invention is not limited to these four formulations.

[0042] The polymerization reaction was carried out feeding intake according to the contents listed in Table 2.

[0043] Table 2 Polymerization Reaction Feeding Table

[0044]

[0045] The choice of solvents, initiators, catalysts and ligands is within the ordinary skill of a person of ordinary skill in the art. Commonly availa...

Embodiment 2

[0047] The preparation of embodiment 2 mirror back paint curtain coating

[0048] The primer and topcoat were prepared respectively according to the contents listed in ingredients table 3 and table 4.

[0049] Table 3 Primer Coating Material List

[0050]

[0051] Total weight of primer: 100 kg. Solid content 65±2%, viscosity: 100-150s (Tu-4 cups, 25°C).

[0052] Solid content refers to the weight fraction of solids in the resin or coating.

[0053] Table 4 list of topcoat materials

[0054]

[0055] Total weight of top coat: 100 kg. Solid content 65±2%, viscosity: 100-150s (Tu-4 cups, 25°C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com