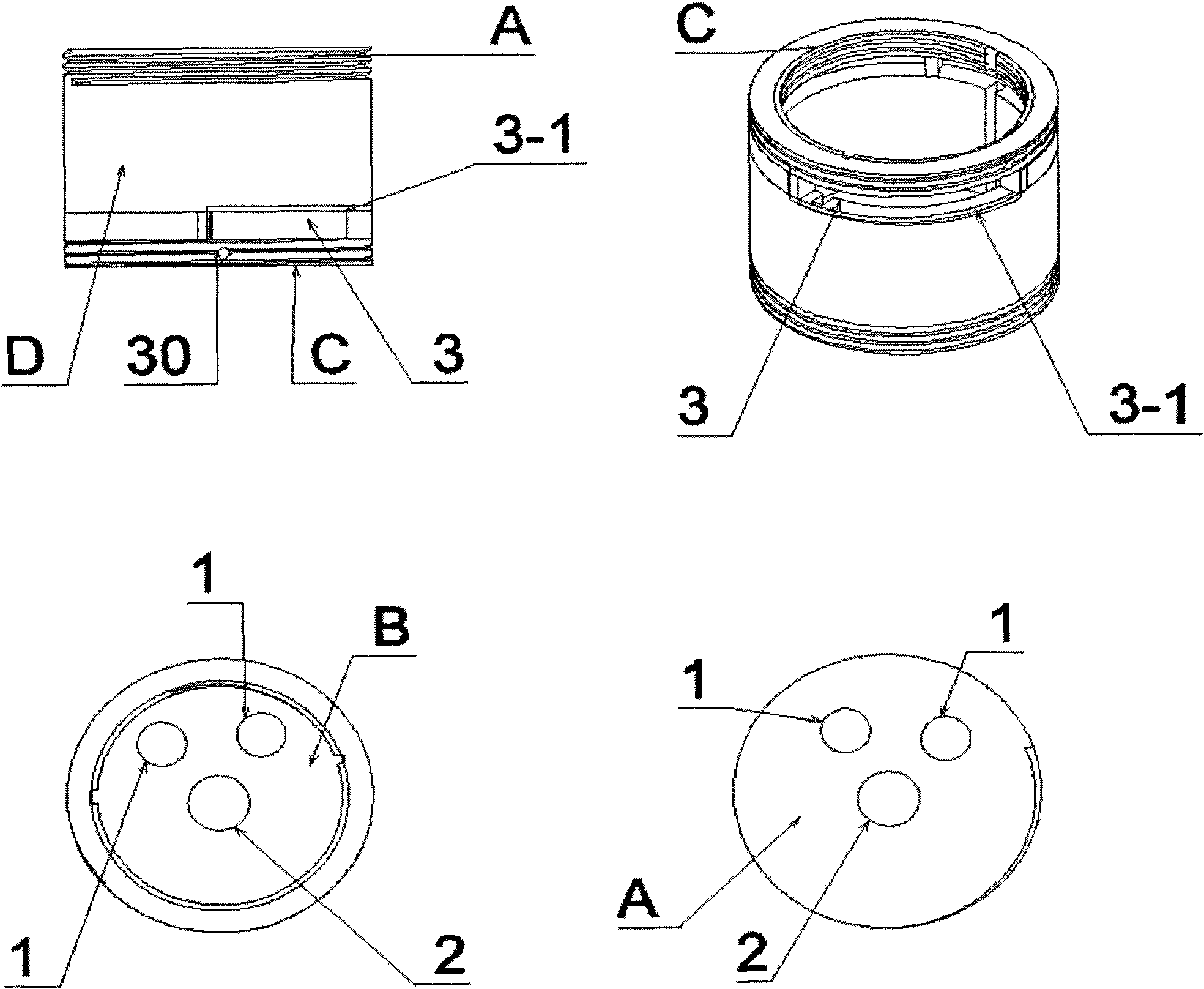

Valve element assembly

A spool assembly and spool technology, applied in multi-way valves, valve devices, engine components, etc., can solve problems such as limited water pressure, difficult design and processing, and large force on the force arm parts of the spool, to achieve Reduces the possibility of water leakage, simple design and processing, and the effect of reducing the angle of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

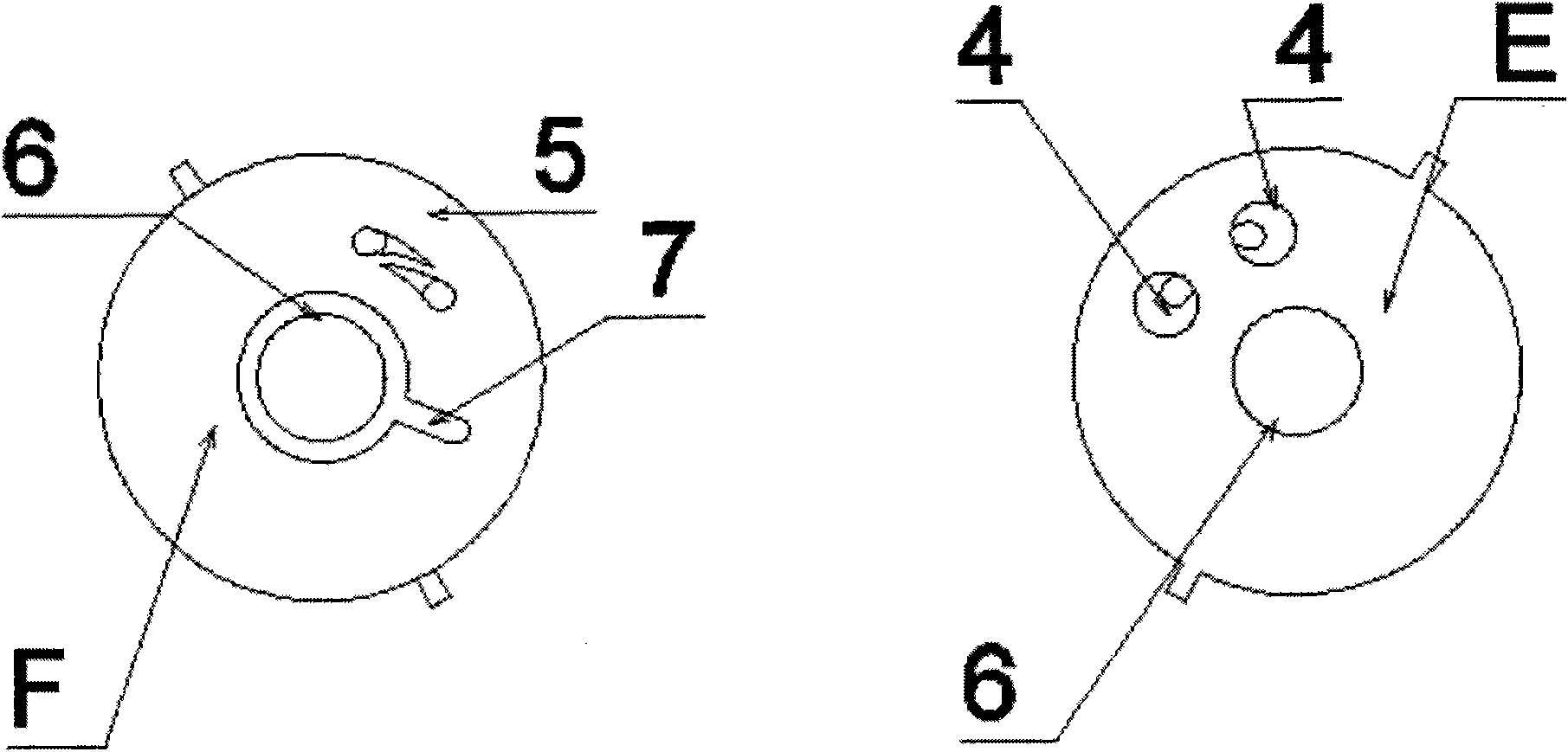

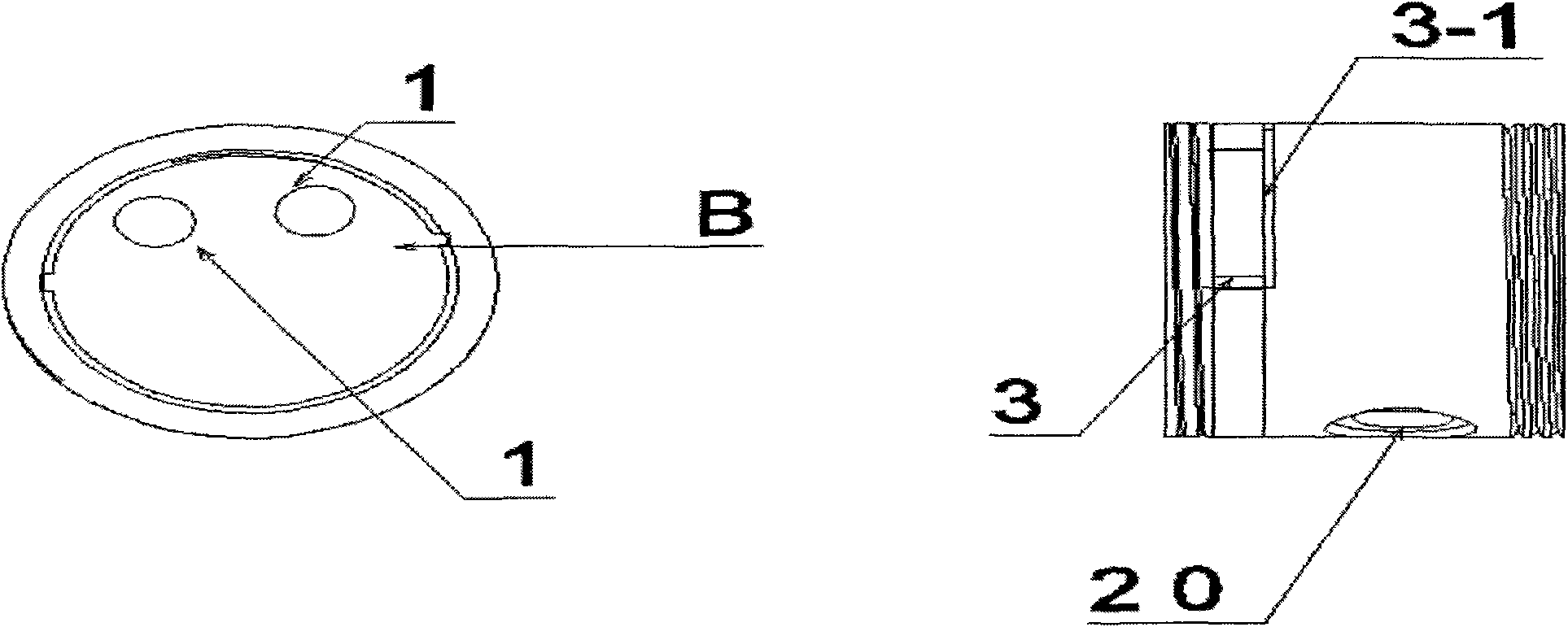

Method used

Image

Examples

no. 3 example

[0058] The third embodiment (explaining that the outer diameter of the movable valve plate is a shaft type---B-1 formula). The movable valve plate c-3 moves along the axis of the inner ring of the limit ring s with its own outer diameter as the axis. The groove 38 of its bottom surface G-3 seals and fits and slides to control the water flow above the two water inlet holes 5 on the top surface F of the water inlet valve plate (b-1). The inner ring of the limit ring s and the side of the movable valve plate c-3 fit and slide. The hollow boss J-3 on the top surface H-3 of the movable valve plate c-3 is embedded in the central hole 51 of the water outlet valve plate d-3, and the two valve plates are sealed and slid. The water flow passes through the groove 38 of the movable valve plate c-3 and the water outlet hole 48 successively, the central hole 51 of the water outlet valve plate d-3, and the spool pressing cap f-3 connection hole 52 flows out of the spool. A flat gasket q-4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com