Heating furnace structure

A technology of heating furnace and heating tank, which is applied in the direction of distillation and separation, boiling equipment, chemical instruments and methods, etc. It can solve the problems of high requirements for on-site restoration construction, poor overall appearance, and difficult transportation, and achieves unchanged functions and simplified packaging. Head and flange structure, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

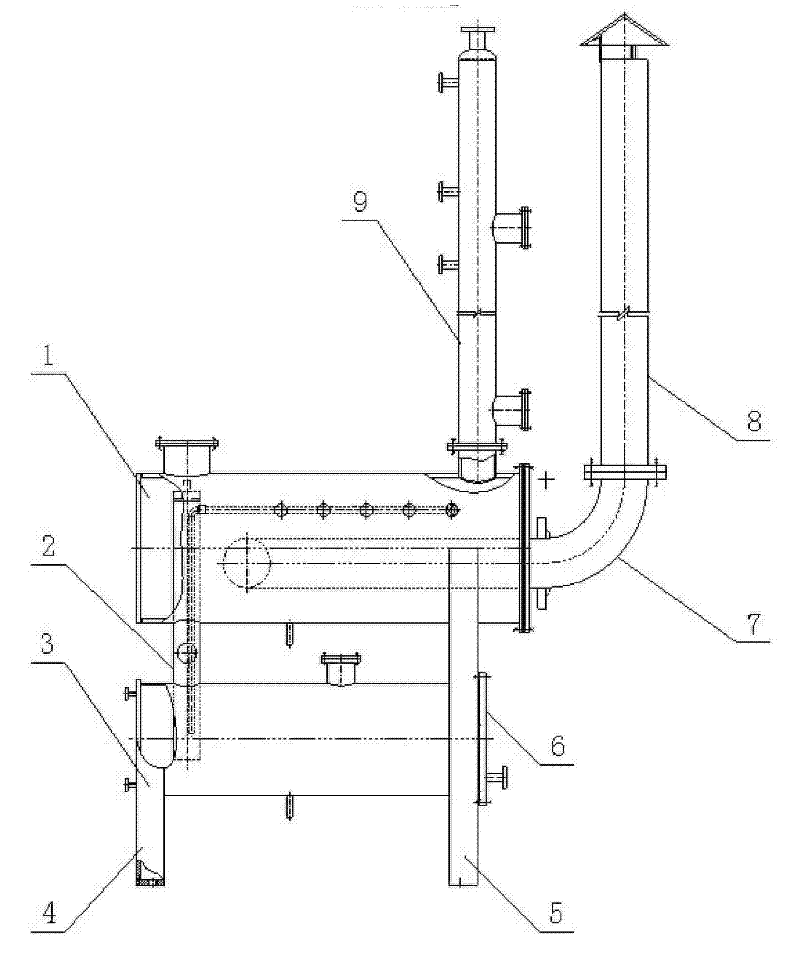

[0025] like figure 1 As shown, the heating furnace structure includes a heating tank 1 and a heat exchange tank 3 connected below the heating tank 1, a liquid-rich rectification column 9 is arranged on the top surface of the heating tank 1, and a flange plate at the end of the heating tank 1 The chimney 8 is connected through the elbow 7, the heat exchange tank 3 is supported by the left support 4 and the right support 5, and the heating tank 1 is connected with the heat exchange tank 3 through the lean liquid rectification column 2 and the extension arm of the right support 5 support; and the left support 4 is connected to the left end surface of the tank body of the heat exchange tank 3, and the right support 5 is connected to the inner side of the flange right end cover 6 of the right end surface of the heat exchange tank 3 tank body.

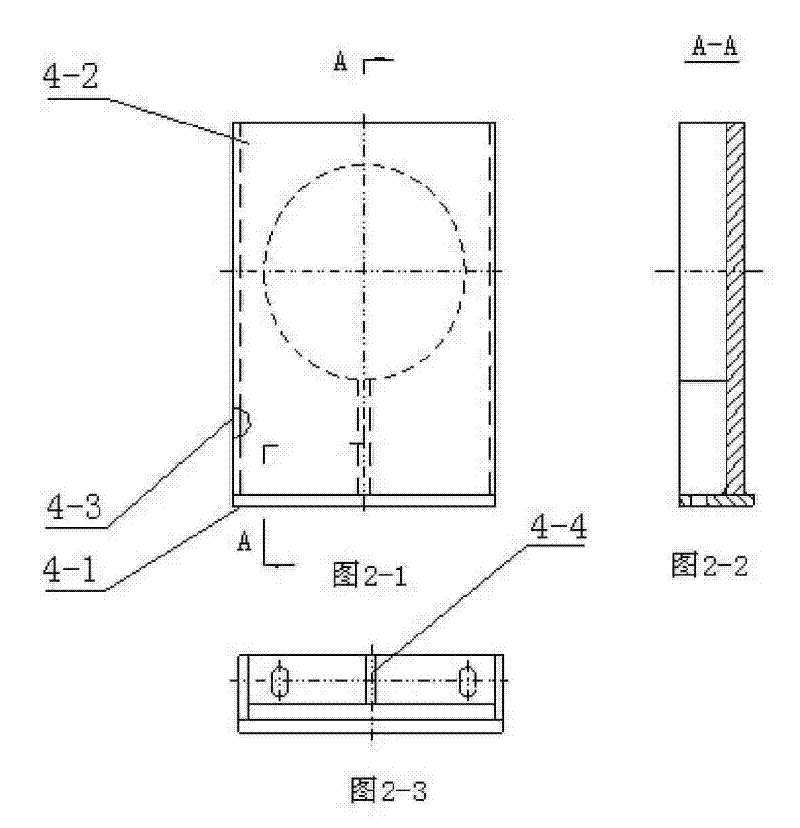

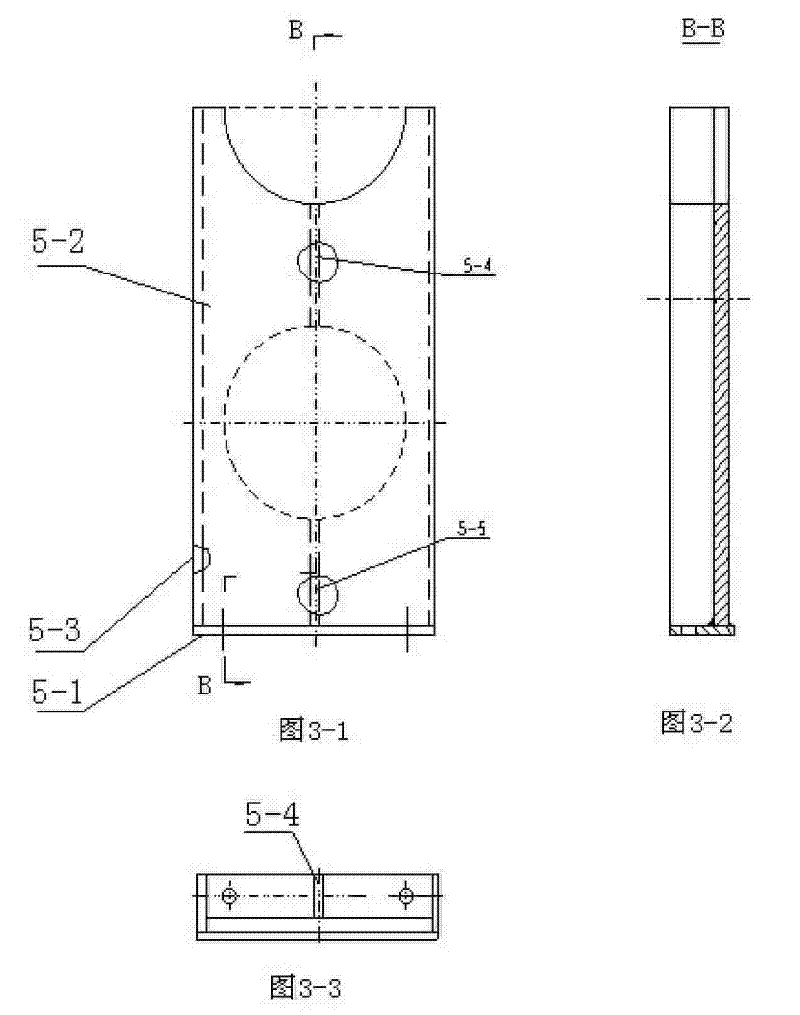

[0026] like figure 2 As shown, the left support 4 is composed of the bottom plate 4-1, the web 4-2, the front and rear side plates 4-3 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com