Structure for supporting a sleeve member in automatic transmission

A technology for automatic transmissions and tubular components, which is applied to vehicle components, components with teeth, transmission parts, etc., and can solve problems such as vibration of tubular components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

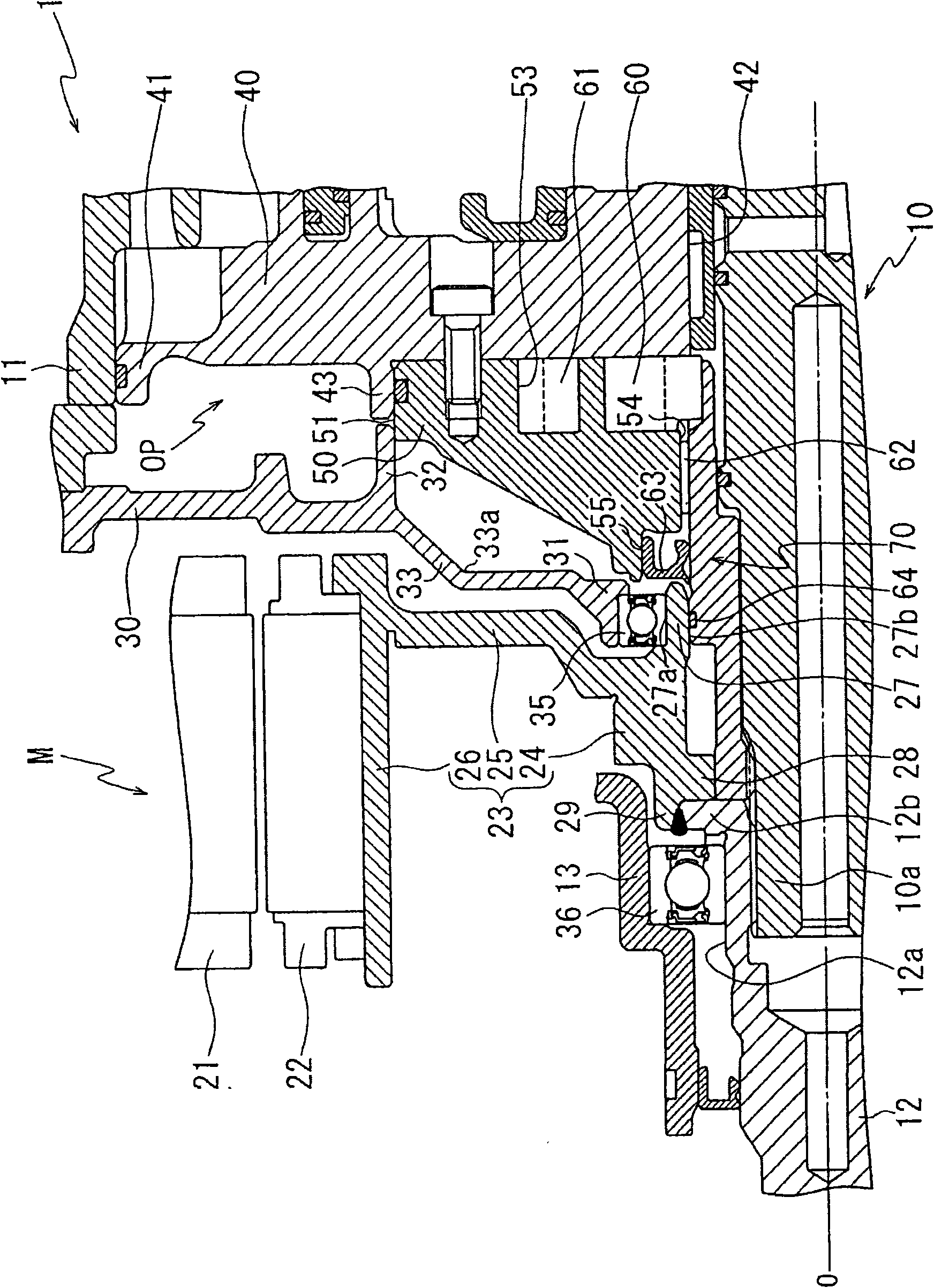

[0035] Next, a case where the support structure of the cylindrical member of the automatic transmission according to the present invention is applied to a cylindrical oil pump drive shaft that transmits rotation of the input shaft to the internal gear of the oil pump will be described as an example.

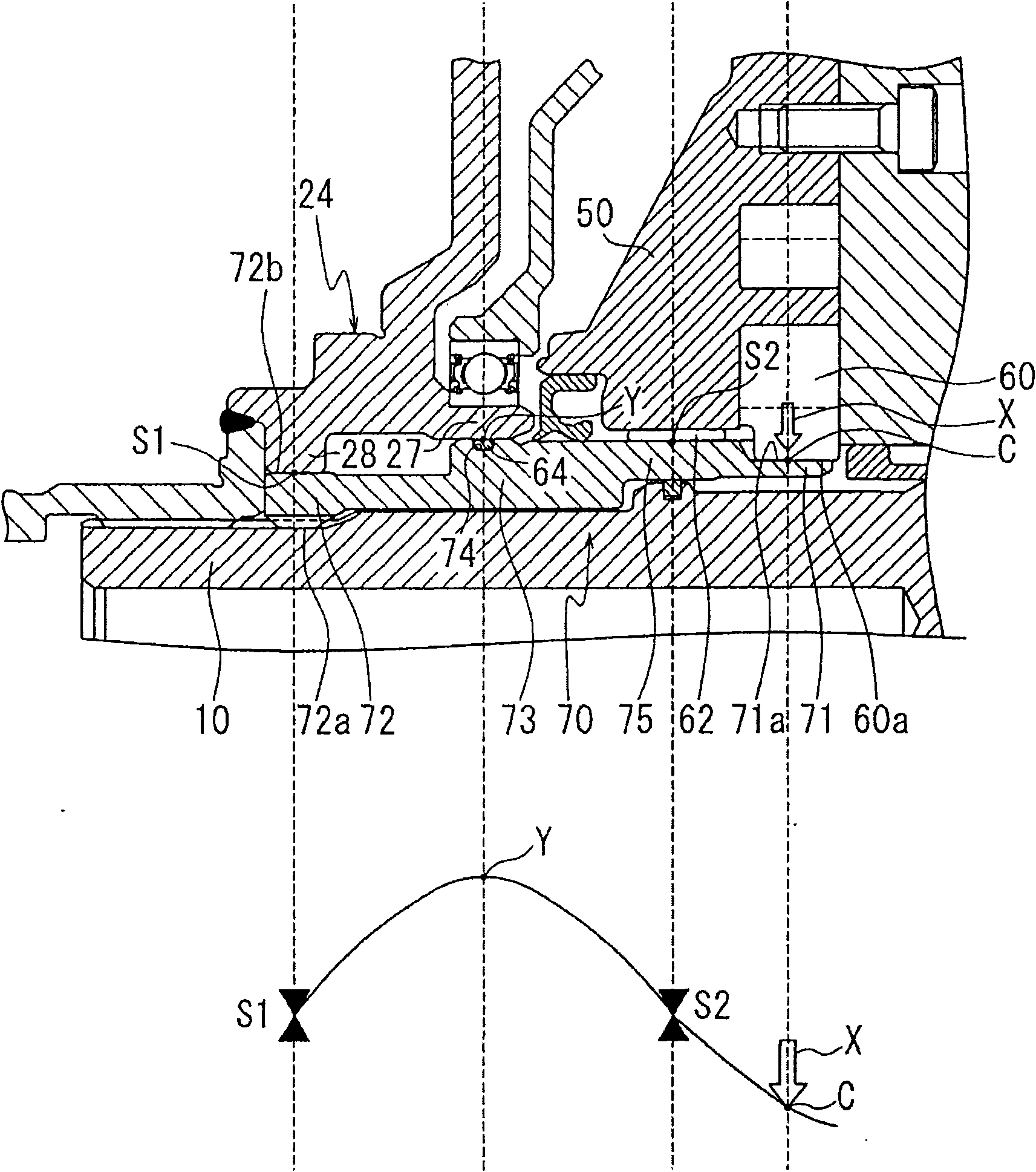

[0036] figure 1 It is a partially enlarged view of an automatic transmission employing the support structure of the embodiment. figure 2 It is a diagram explaining the stress acting on the drive shaft of the oil pump.

[0037] In the automatic transmission 1, along the axial direction of the input shaft 10 of the automatic transmission 1, an electric motor M and an oil pump OP are arranged adjacent to each other in order from the left side in the figure (the engine side not shown), and the oil pump drive shaft 70 is inserted outside the input shaft 10. axis 10.

[0038] The electric motor M is composed of a stator 21 provided on an unillustrated inner peripheral surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com