Multi-functional elevator

A lift and multi-functional technology, applied in the field of lifts, can solve the problems of inconvenient use and poor safety of lifts, and achieve the effects of small footprint, easy storage, and compact structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

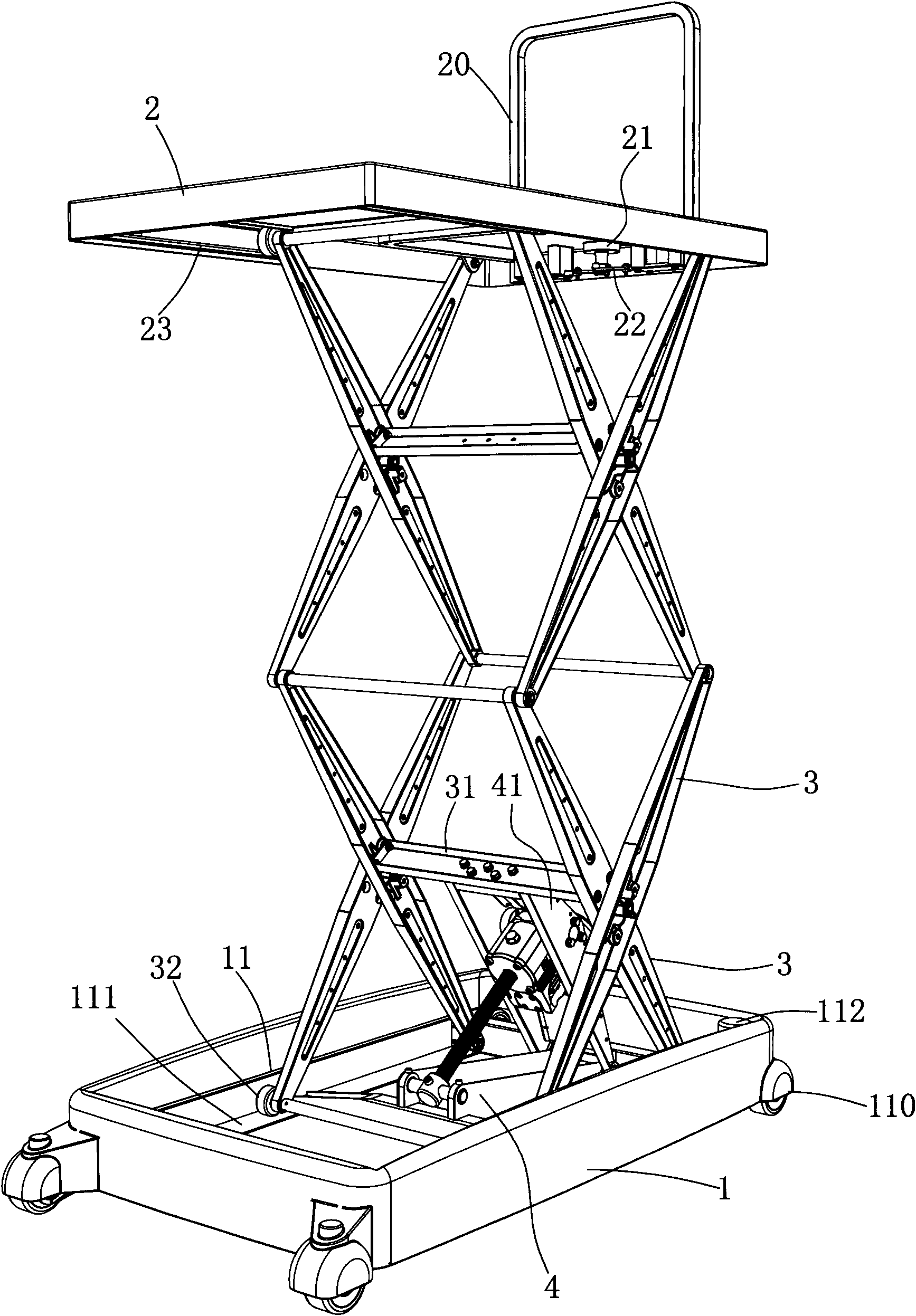

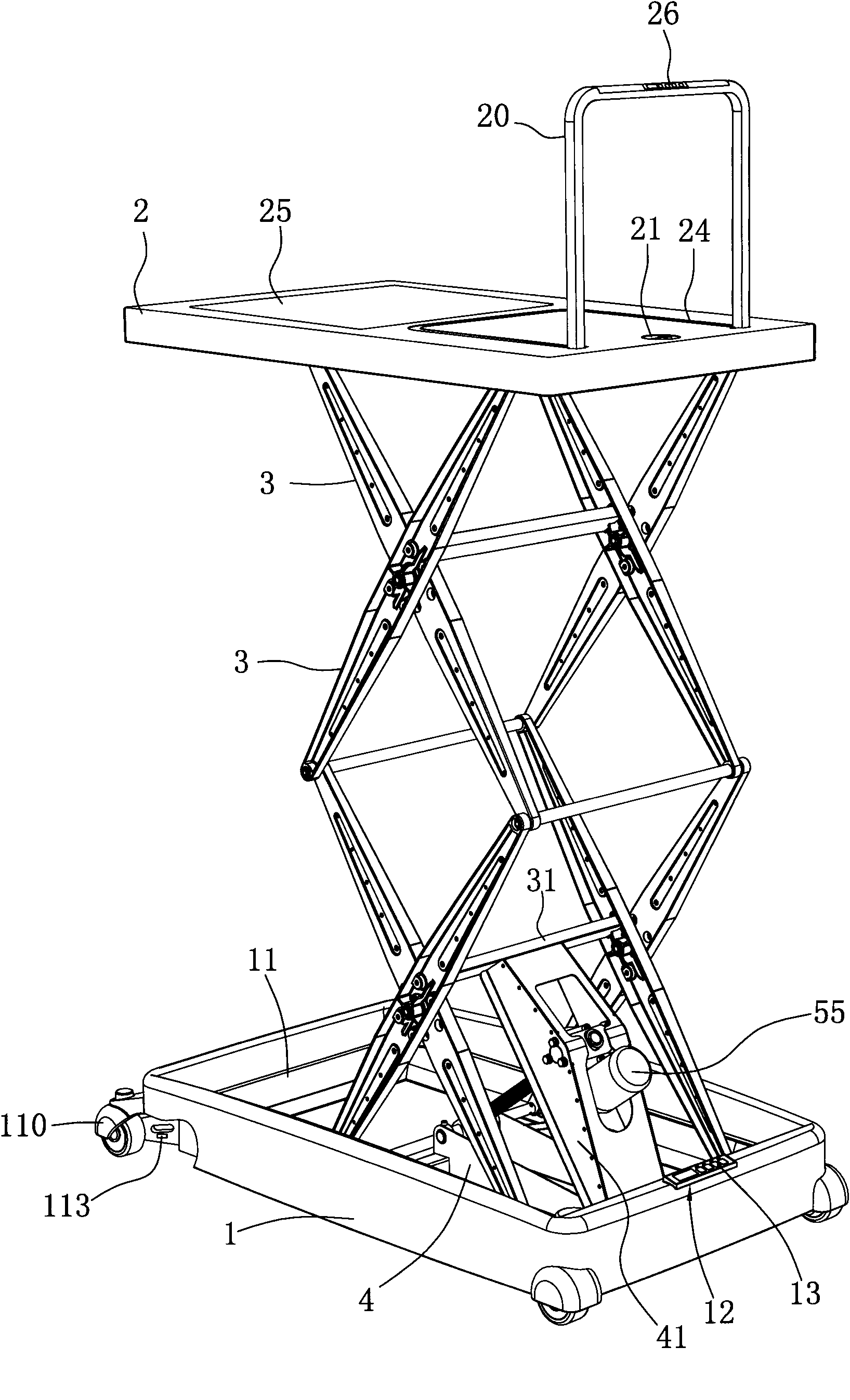

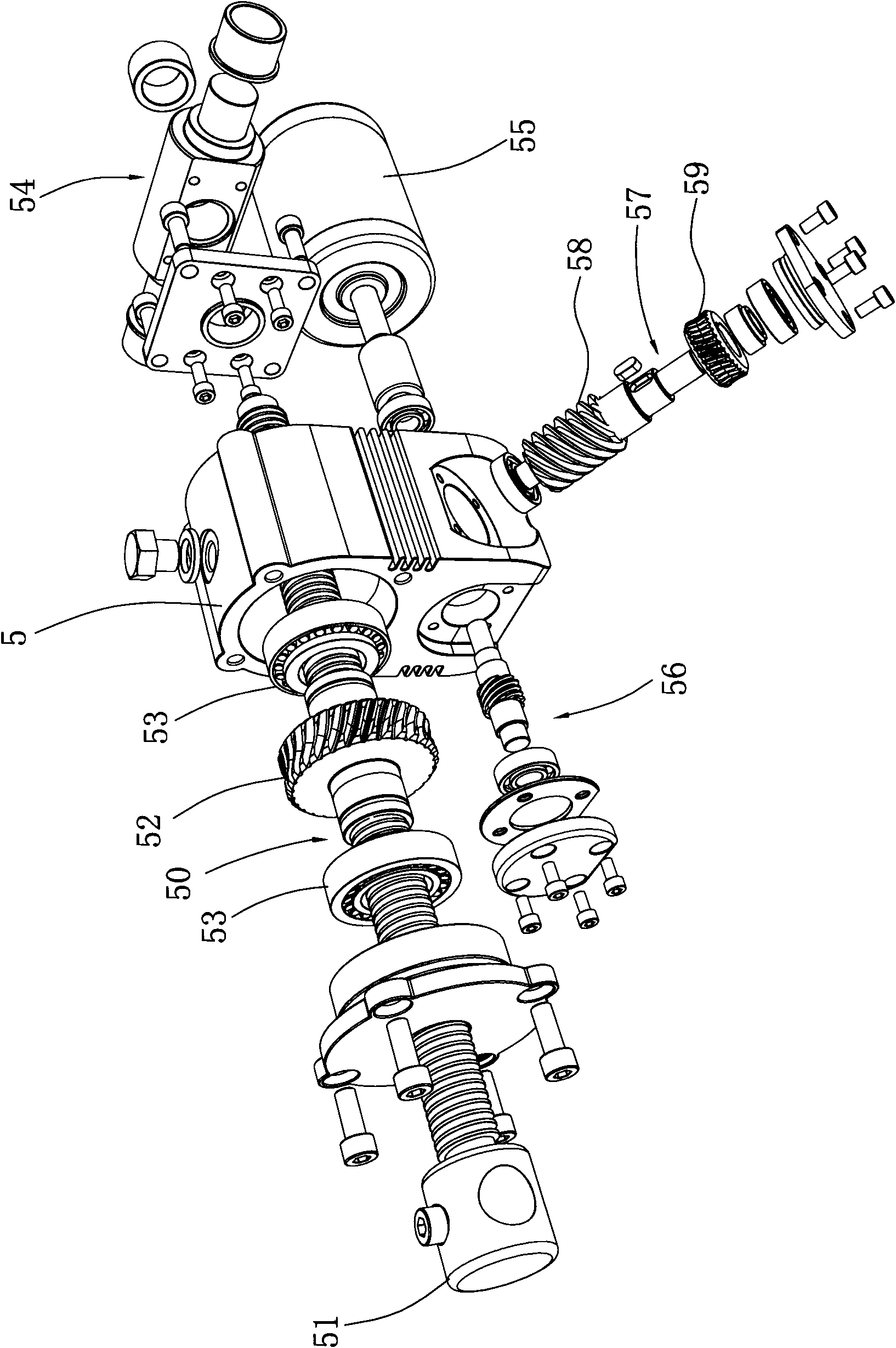

[0020] Such as figure 1 , figure 2 As shown, the present invention is a multi-functional elevator, including a chassis assembly and a lifting platform assembly, a hinged scissor mechanism between the chassis assembly and the lifting platform assembly to support or drive the lifting platform assembly, and a driving device is set on the chassis assembly to drive the scissors The expansion and contraction of the mechanism, the driving device is controlled by the controller 12 that is located on the chassis assembly.

[0021] The lifting platform assembly includes a lifting platform 2, one end of the lifting platform 2 is movable to set a folding railing 20, a link mechanism 22 is arranged at the bottom of the lifting platform 2 to connect with the bottom of the folding railing 20, and a groove for storing the folding railing 20 is arranged on the table of the lifting platform 2 24 and the rotating knob 21 of the control link mechanism 22, the folding railing 20 can facilitate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com