Magnetic suspension combined ball bearing

A ball bearing and magnetic suspension technology, applied in the direction of bearings, bearing components, shafts and bearings, can solve the problems of easy to wear balls, and achieve the effect of increasing service life and reducing radial pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below according to accompanying drawing and specific embodiment the present invention is further described:

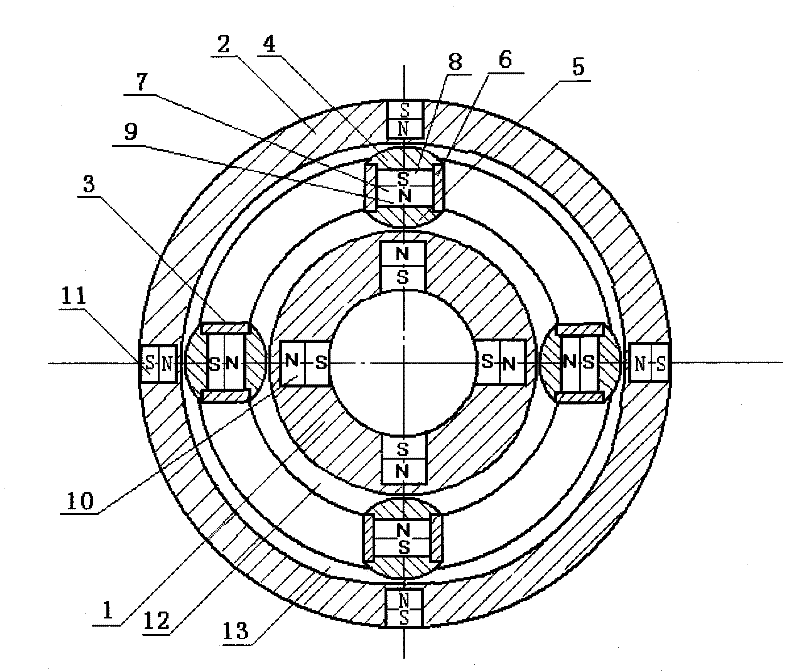

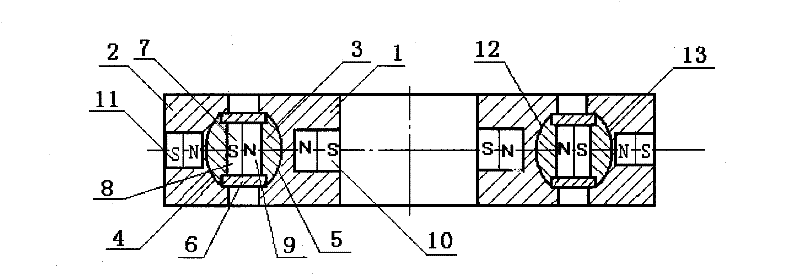

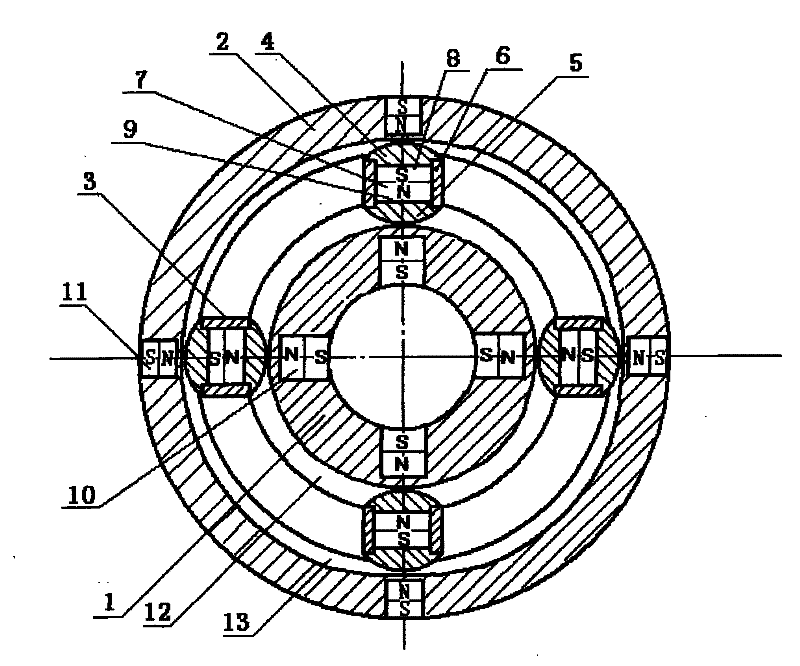

[0010] figure 1 The schematic diagram of the structure of the magnetic suspension combined ball bearing shown and figure 2 shown figure 1 The top view of the magnetic suspension combined ball bearing includes an inner ring (1), an outer ring (2) and balls (3). The ball (3) is dynamically fitted between the inner ring (1) and the outer ring (2). The inner ring (1) The center line of the outer ring (2) is the same, and the ball (3) is composed of an upper ball cover (4), a lower ball cover (5), a through pipe (6) and a moving magnetic pole (7), and the upper ball cover ( 4) Interference fit with the upper nozzle (8) of the through pipe (6), interference fit between the lower spherical cover (5) and the lower nozzle (9) of the through pipe (6), the moving magnetic pole (7) is located in the through pipe (6) In the cavity formed by the upper ball cover (4) and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com