Mechanical pipeline under-pressure blocker and blocking method thereof

A mechanical and blocker technology, applied in the direction of mechanical equipment, pipe components, pipes/pipe joints/pipe fittings, etc., can solve the problems of easy combustion, difficult construction, pollution, etc., to reduce the construction period and construction cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

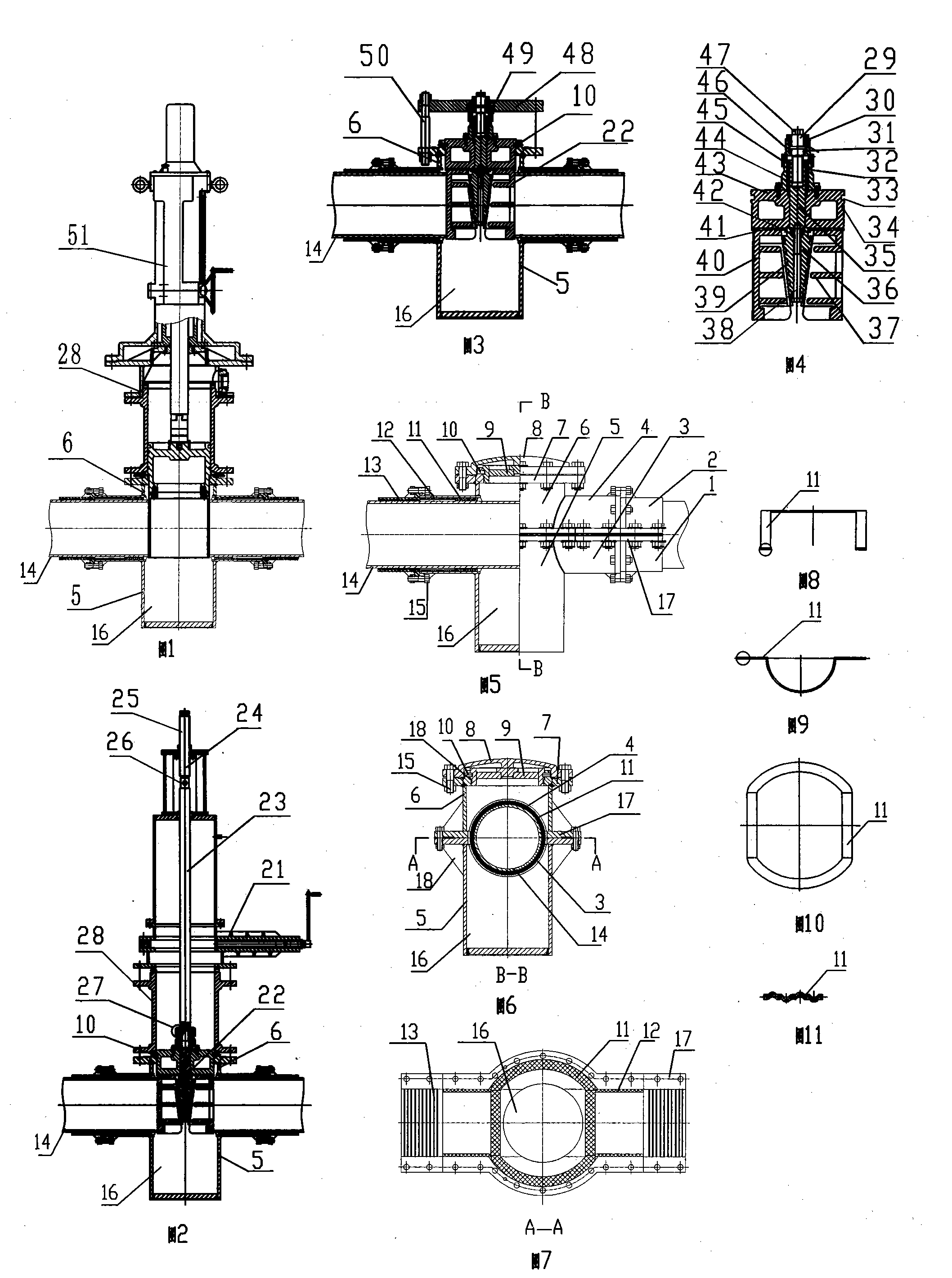

[0046] The conformal sealing pad is made of oil-resistant rubber, which acts as a seal between the upper and lower bodies and the pressure pipeline.

[0047] The supporting rubber pad is made of oil-resistant asbestos rubber sheet, which plays a role in limiting the infinite compression of the conformal sealing rubber pad.

[0048] The inner blind plate is a cylindrical piston, with an annular sealing groove and a limit groove on the side, and a connecting thread protrusion in the center, which is mainly used to seal the dismantled device after the blocking is completed.

[0049] The outer blind plate plays the role of sealing and protection.

[0050] The anti-skid hoop is divided into upper and lower halves. The radius of the inner arc is similar to that of the pipe. There are multiple grooves on the arc, flanges on both sides, and a flat flange on one end to connect the upper and lower bodies.

[0051] How to install and use

[0052] ① After cleaning the curved surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com