High-power LED lamp

A LED lamp, high-power technology, applied in cooling/heating devices of lighting devices, lighting and heating equipment, electrical components, etc., can solve problems such as high energy consumption, slow down heat dissipation efficiency, and increase costs, so as to improve thermal efficiency , expand the application field, avoid the effect of loosening or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

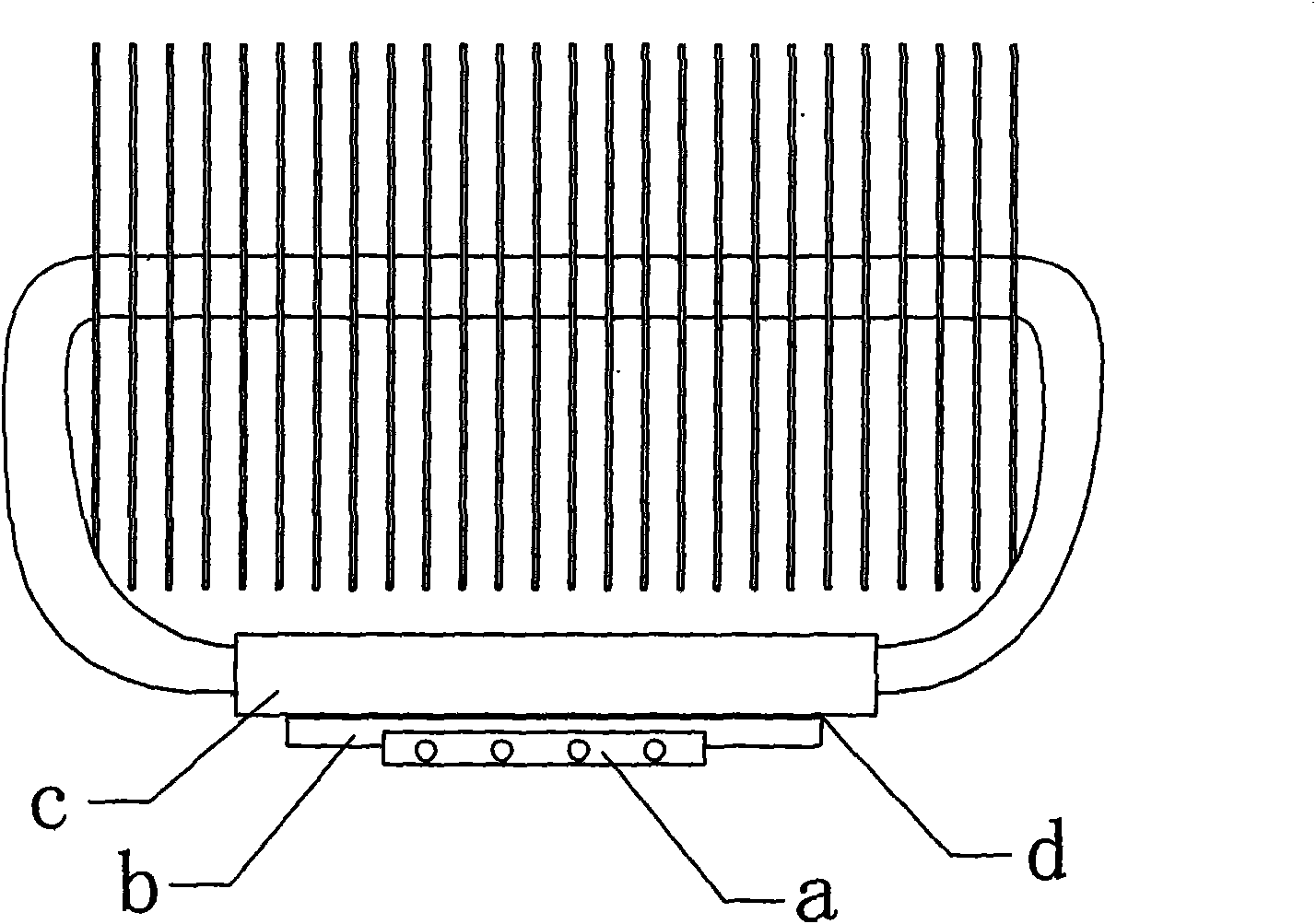

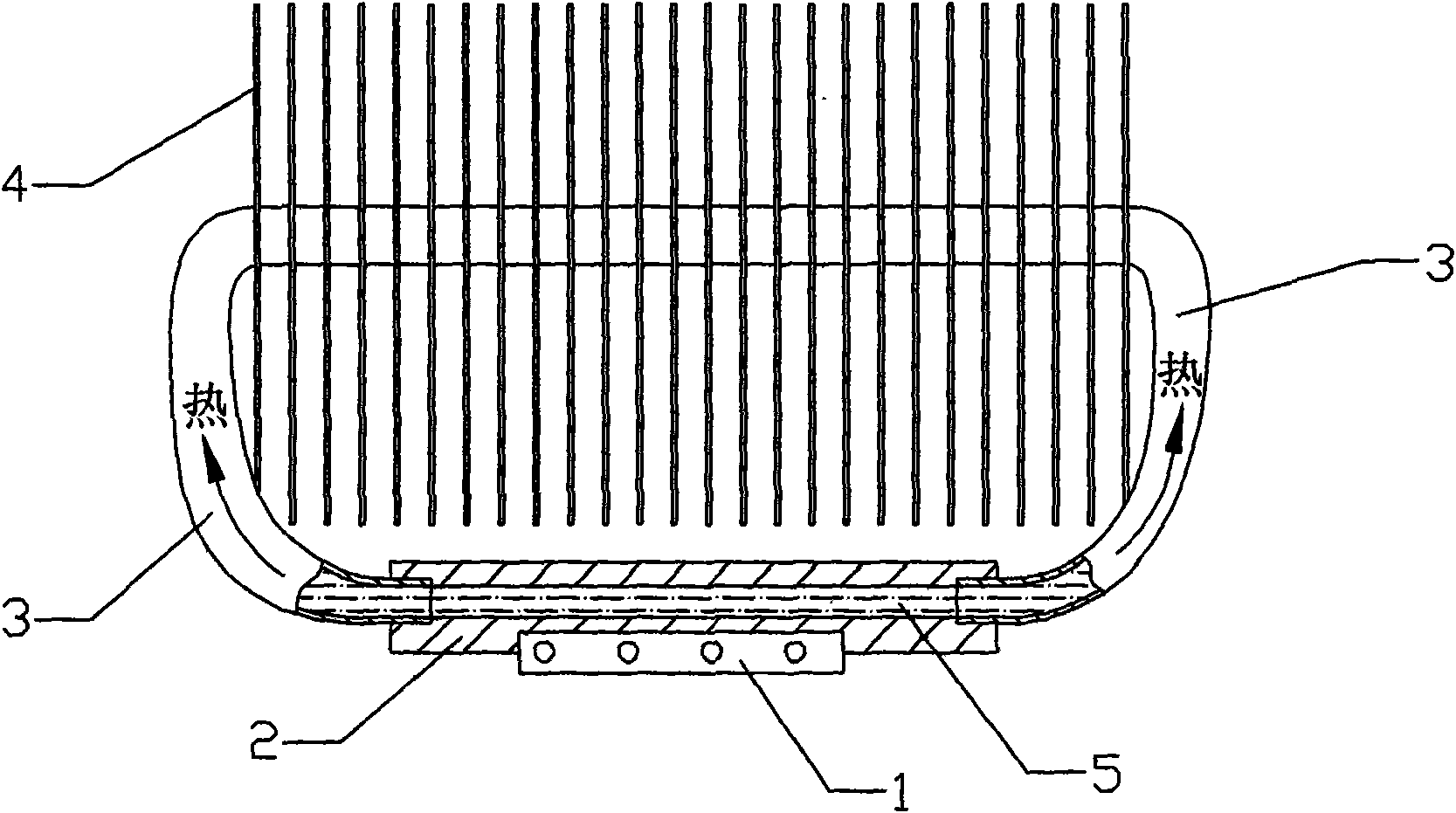

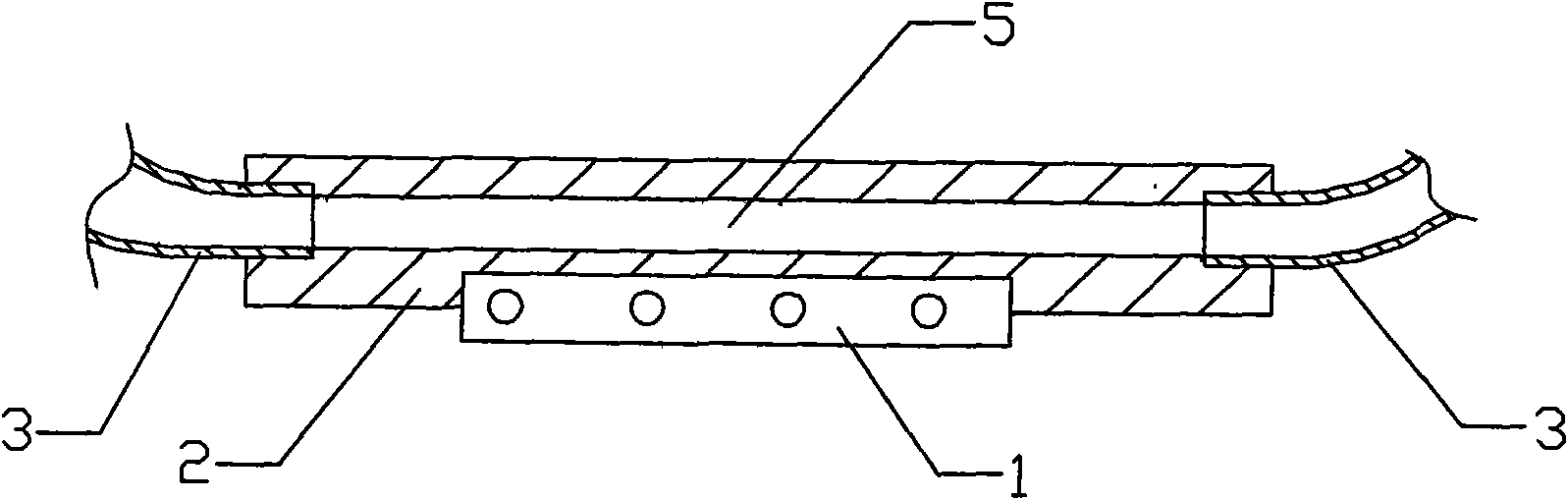

[0014] According to attached figure 2 As shown, the high-power LED lamp described in the present invention is mainly aimed at the high-power LED lamp with centralized packaging and heat pipe radiator (with cooling fins) structure. It includes an LED chip 1 and a heat pipe radiator, and the heat pipe radiator serves as An independent heat dissipation mechanism can conduct the heat generated by the LED chip 1 to the outside to prevent the LED chip 1 from overheating. In the LED lamp with centralized structure involved in the present invention, its heat pipe radiator includes a refrigerant plate 2 and a heat dissipation pipe 3, the heat dissipation pipe 3 is connected to the refrigerant plate 2, and the heat dissipation pipe 3 can be an aluminum pipe, a copper pipe or a stainless steel pipe, At the same time, in order to enhance the heat dissipation effect of the LED la...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap