Digital level capable of automatically measuring

A technology of digital leveling and automatic measurement, which is applied in the direction of measuring devices, height/level measurement, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

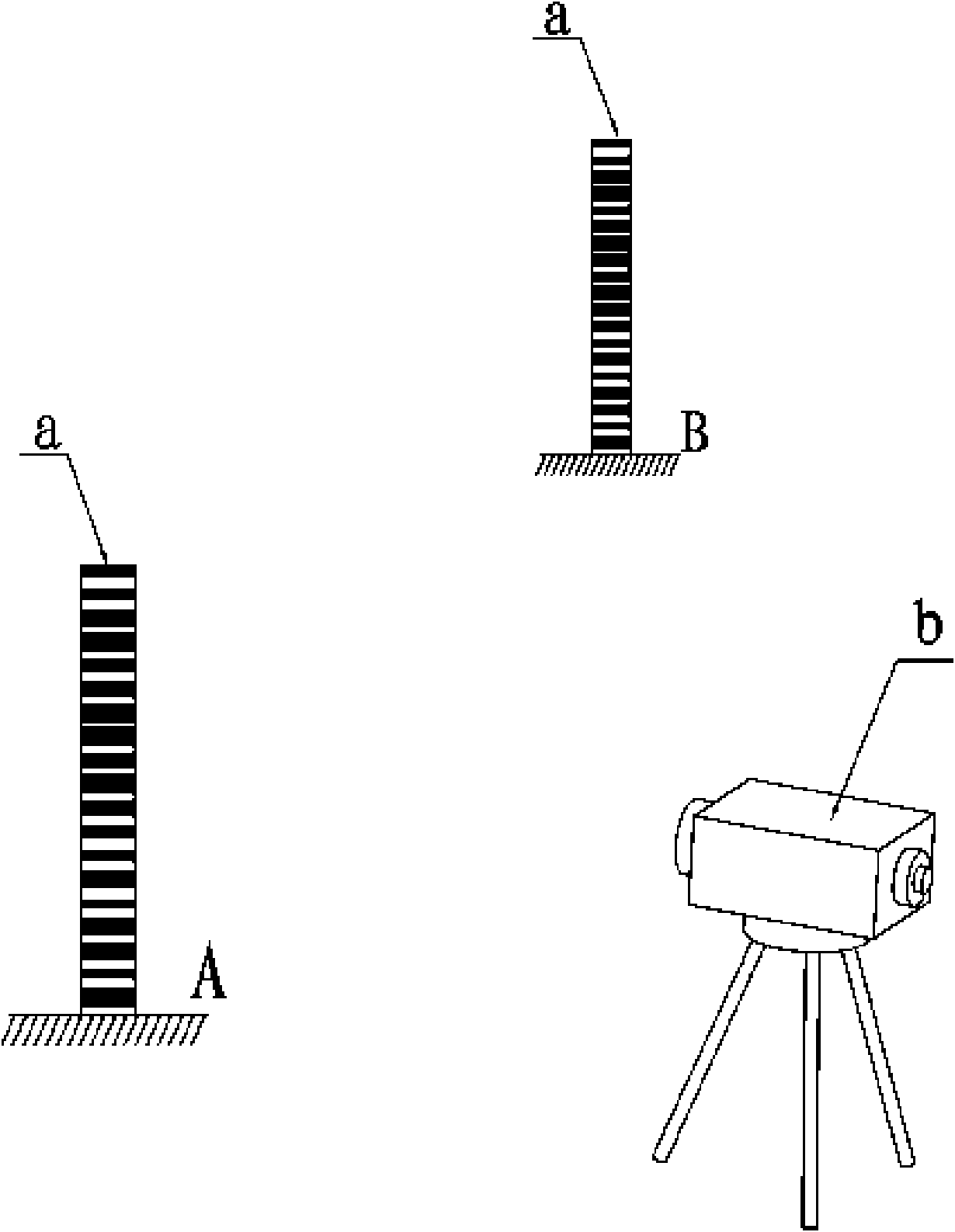

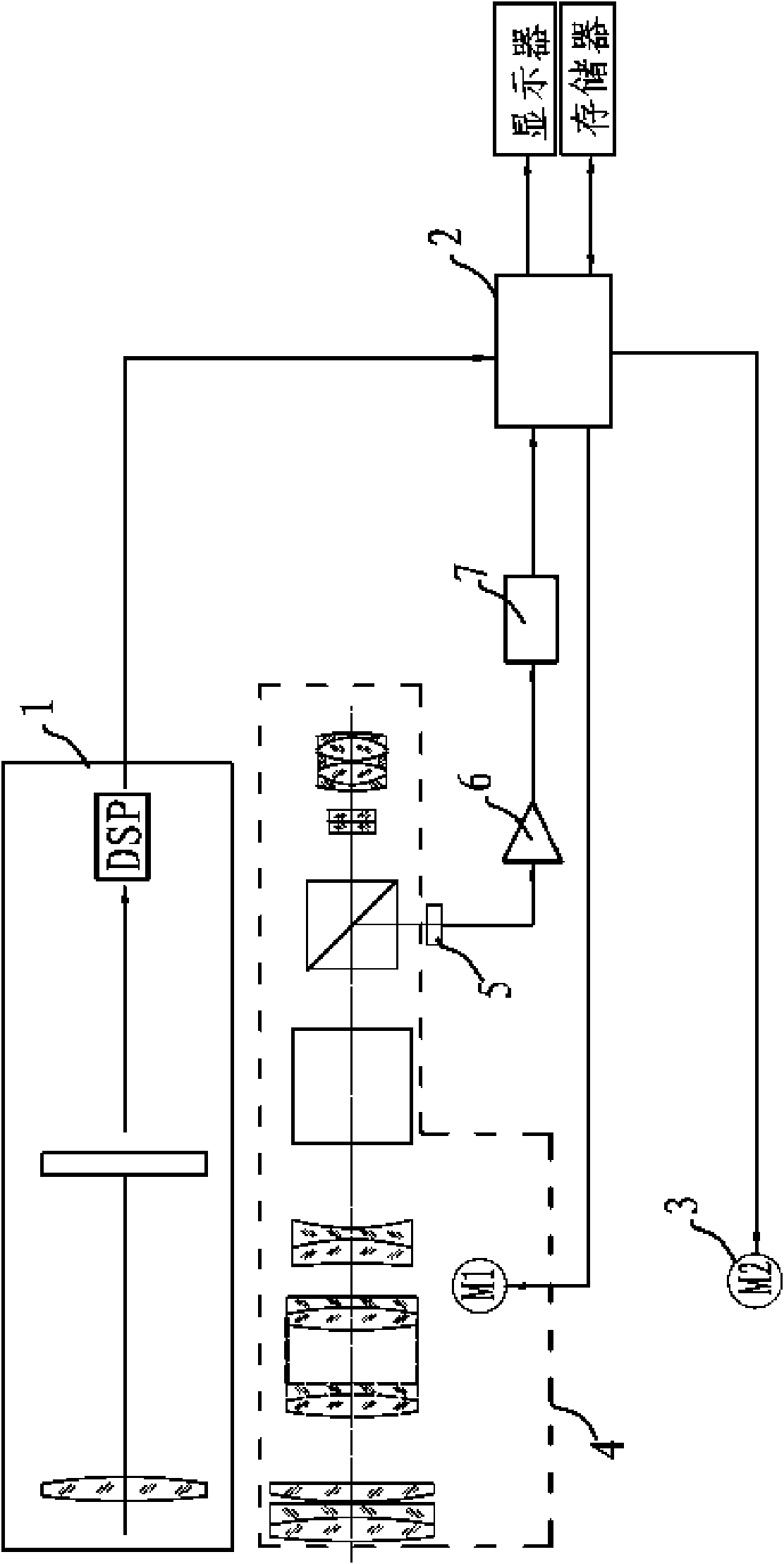

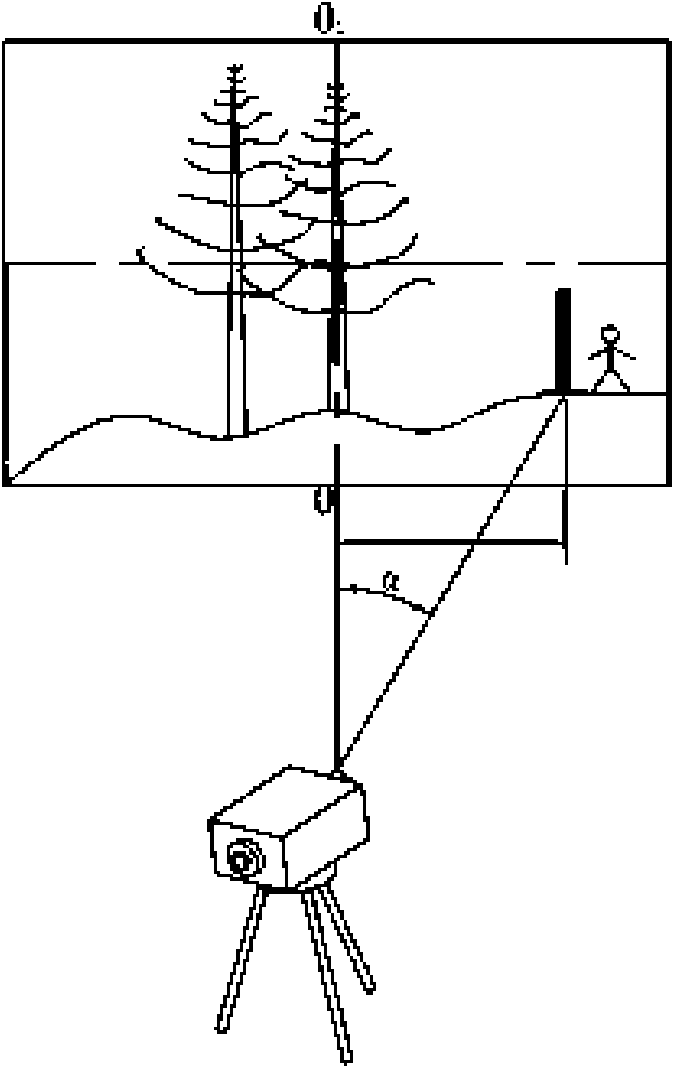

[0025] See Figure 1-6, a digital level for automatic measurement of the present invention, comprising: a wide-angle camera processing system 1, which is used to find a scale a around under the drive of a horizontal rotating base 3, and then calculate the azimuth and distance where the scale a is located; The system 4 is used to adjust the orientation through the horizontal rotation base 3 according to the azimuth and distance of the scale a, and automatically adjusts the focus after aligning with the scale a; the CCD device 5 is used to obtain the scale through the telescope focusing system 4 after focusing The precise image of a; CPU unit 2, for controlling the horizontal rotation base 3 to rotate corresponding angles according to the azimuth and distance where the scale a is located so that the telescope focusing system 4 is aligned with the scale a, and then drives the telescope focusing system 4 to the corresponding focal length, and acquire the image of the scale a forme...

Embodiment 2

[0034] On the basis of embodiment 1, the digital level for automatic measurement of the present embodiment has the following deformations:

[0035] The laser reflective film or laser reflective coating is provided on the used scale a; Light to determine the azimuth and distance where the scale a is located; the level b also includes: a CPU unit 2, a telescope focusing system 4 and a CCD device 5; the CPU unit 2 controls the rotation of the horizontal rotating base 3 according to the azimuth and distance of the scale a to the azimuth, and control the telescope focusing system 4 to automatically focus, and obtain the image of the scale a formed in the CCD device 5, and finally calculate the elevation and distance of the scale a, and store it in the memory.

[0036] Wherein, the pattern on the used scale a is a black and white barcode; when the CPU unit 2 controls the quasi-scale a to focus, the CPU unit 2 drives the horizontal rotating base 3 and the telescope focusing system 4 ...

Embodiment 3

[0038] On the basis of embodiment 1, the digital level for automatic measurement of the present embodiment has the following deformations:

[0039] The used scale a is provided with a GPS receiver for detecting the position of the scale a and a wireless signal transmitting device for transmitting the position information of the detected scale a as a wireless signal.

[0040] The level b includes: a wireless signal receiver for receiving the wireless signal and obtaining the position information of the scale a, a GPS receiver for detecting the position of the level b, a CPU unit 2, a horizontal rotating base 3, a telescope Focusing system 4 and CCD device 5; CPU unit 2 calculates the azimuth and distance of scale a relative to level b according to the position information of level b and the position information of scale a, and then rotates horizontally according to the azimuth and distance The base 3 adjusts the orientation of the telescope focusing system 4, then controls the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com