Display panel and sealing structure

A display panel and sealing structure technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of poor reliability, insufficient structural strength, and insufficient mechanical strength of display panels, so as to increase process capability and stability, shrink The width of the frame glue and the effect of increasing the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

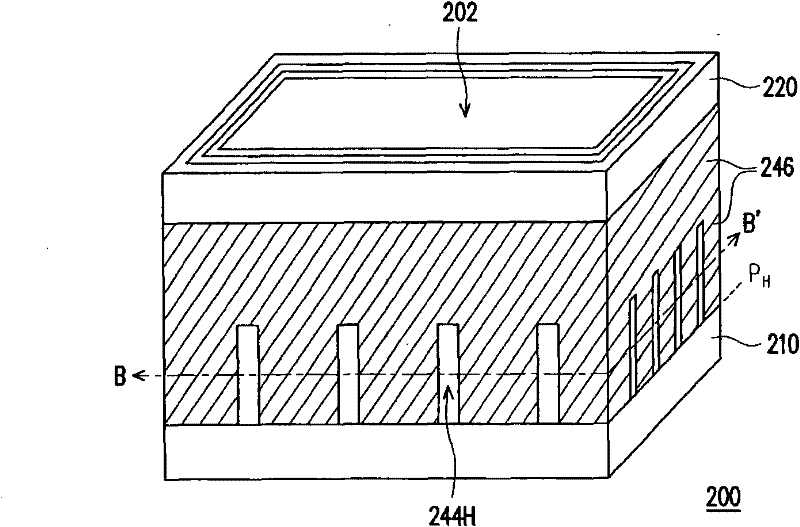

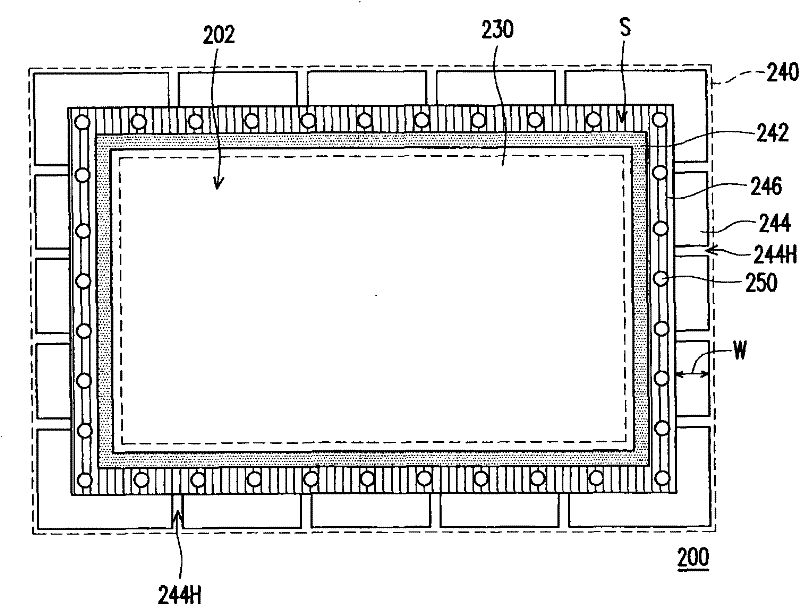

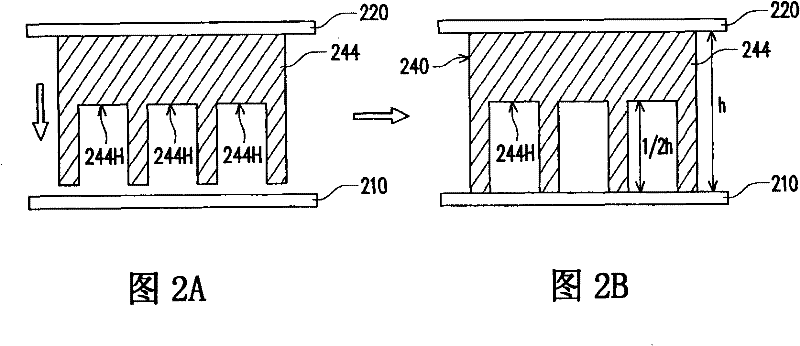

[0047] The present invention mainly proposes a sealing structure in which the frame glue is sandwiched between the inner and outer retaining walls, and the inner retaining wall and the outer retaining wall on both sides of the frame glue are used to reinforce the overall structural strength, so that the display panel is shrinking When the width of the frame is limited, the sealing structure exhibits a certain degree of structural strength within the limited width. In addition, when the frame glue process is carried out, the predetermined structure on the outer retaining wall provides a buffer accommodation space for the frame glue, so that the frame glue process can obtain a larger process margin, and, by being located Part of the sealant in the predetermined structure of the outer retaining wall can further increase the overall structural strength of the sealing structure and the adhesion between it and the upper and lower substrates. The sealing structure of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com