Pin wiring structure of card insertion end of flexible printed circuit board

A flexible printing and circuit board technology, applied in the directions of printed circuit components, secondary processing of printed circuits, reinforcement of conductive patterns, etc., can solve the problems of process accuracy and pin width limitations, breakage of traces 2110, short circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

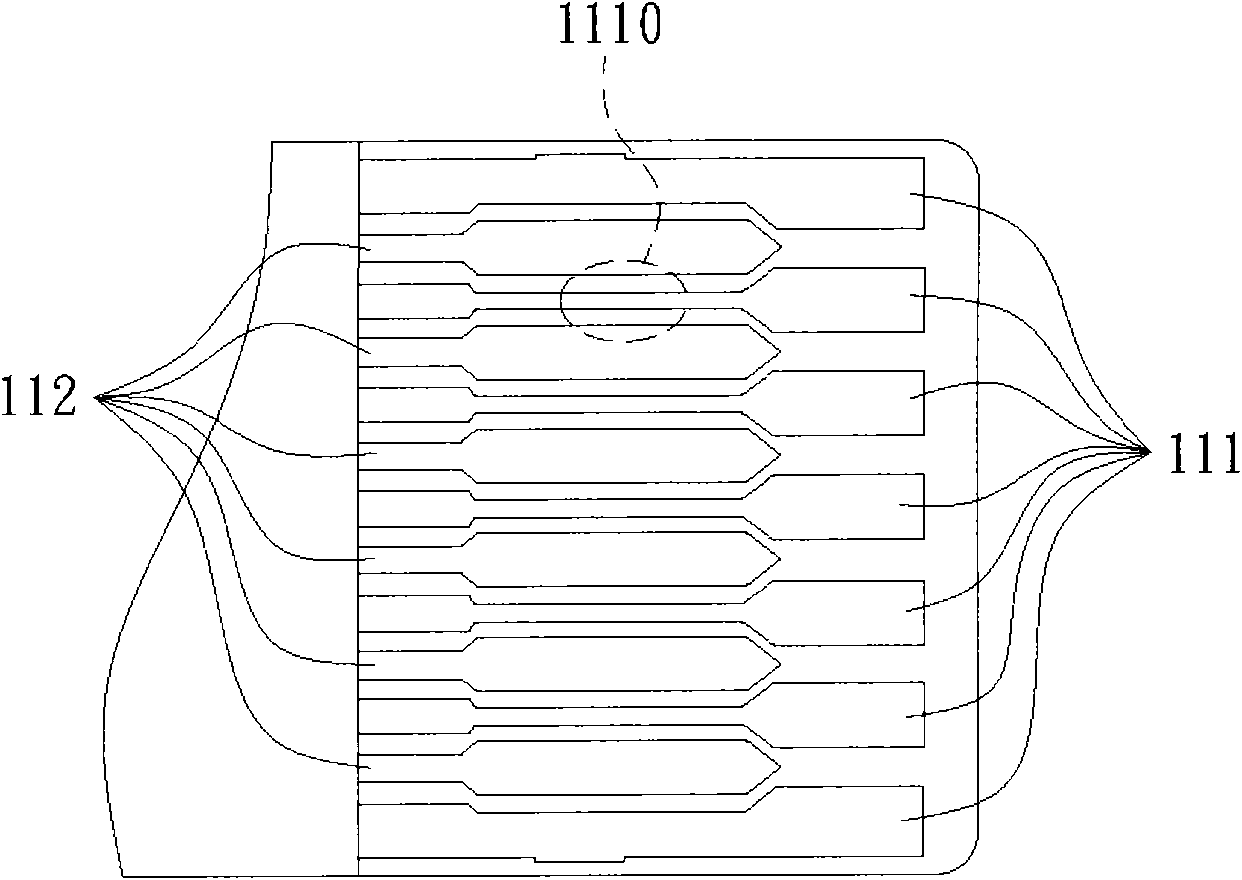

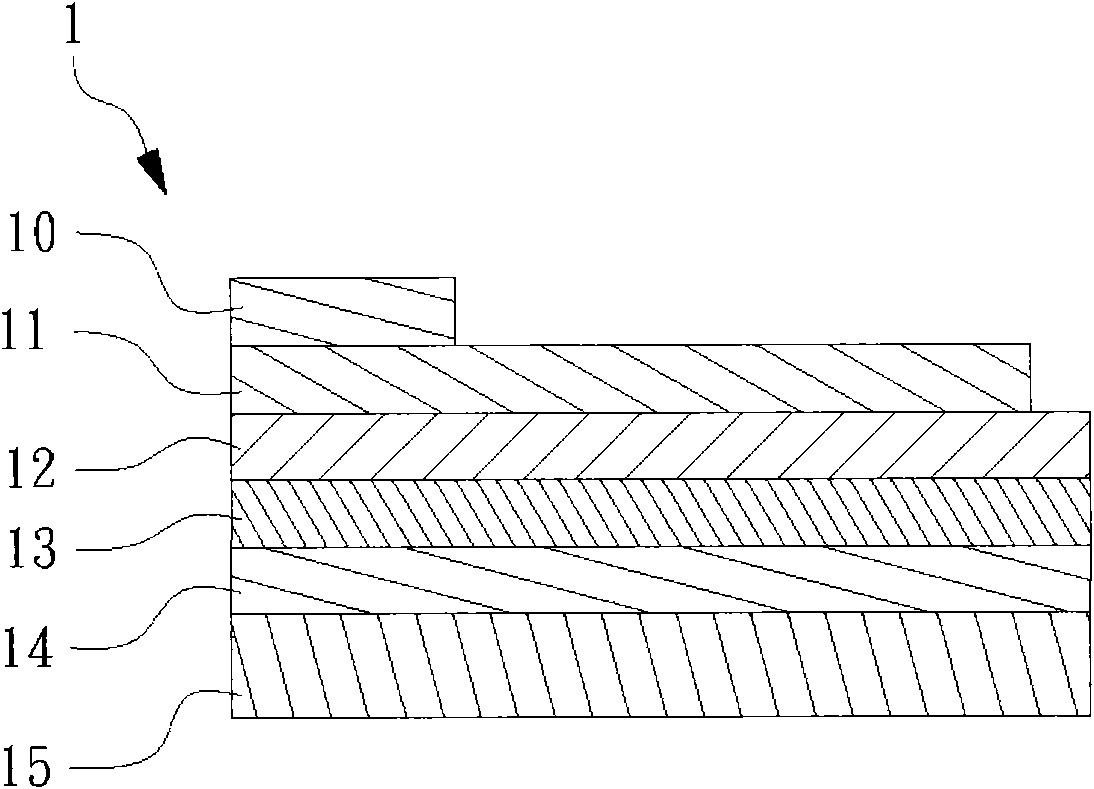

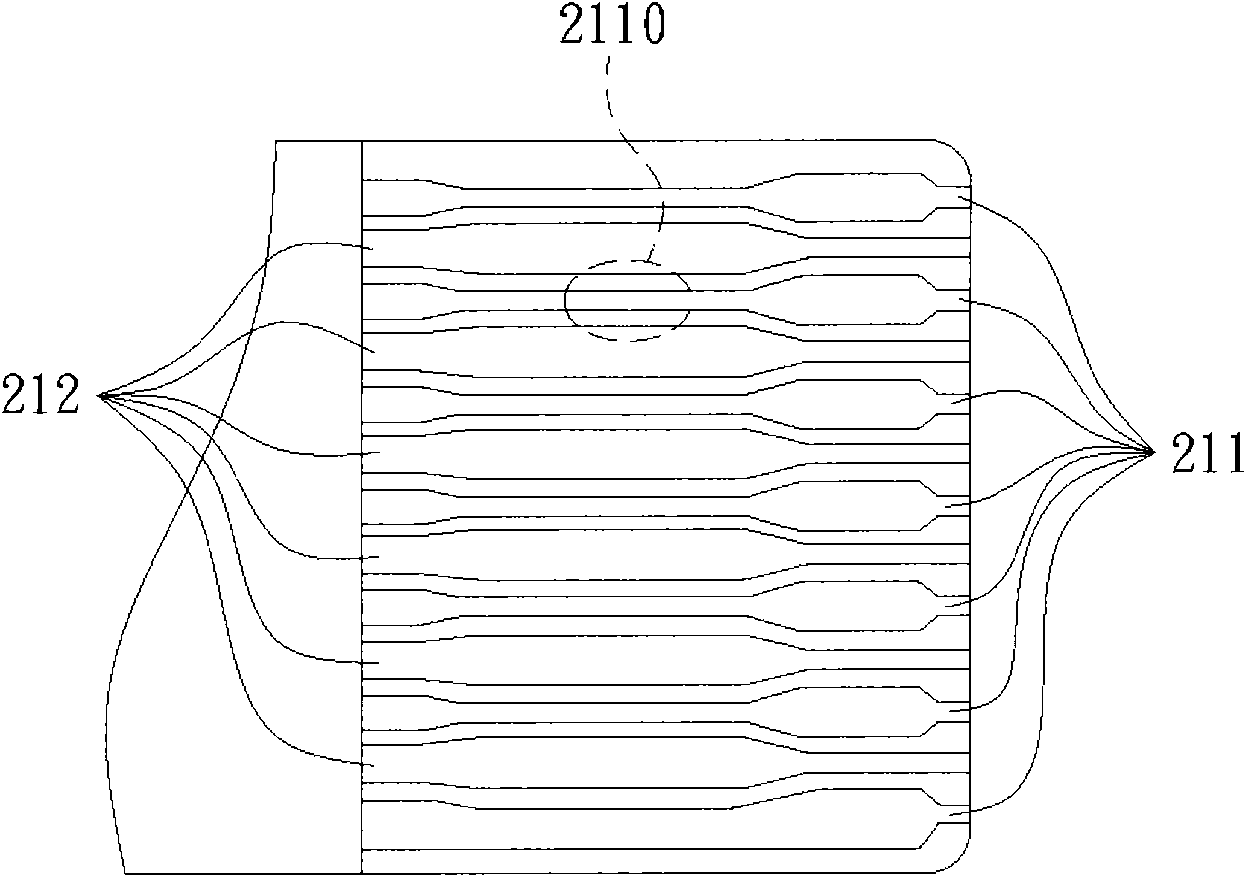

[0051] See Figure 3A , Figure 3B and Figure 3C , which is a schematic diagram of the wiring structure of the pins at the card end of the flexible printed circuit board of the present invention, wherein Figure 3A and Figure 3B for the top view, Figure 3C is a sectional view.

[0052] The card insertion end 3 of the flexible printed circuit board of the present invention is sequentially provided with a first protective layer 30, a first conductive layer 31, a substrate 32, a second conductive layer 33, and a second protective layer. 34 and a reinforcing plate 35 are stacked, and the first conductive layer 31 and the second conductive layer 34 can be made of metallic copper.

[0053] The first conductive layer 31 is formed with a plurality of first traces 311 (parts of the first traces 311 are covered by the first protection layer 30, indicated by dotted lines), and one end of each of the first traces 311 is respectively extended with a first A pin 312, the first cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com