Chain saw provided with a lubrication device and method implemented for performing said lubrication

A technology of chain saws and lubricating fluids, which is applied in the direction of chain saws, lubricating parts, engine lubrication, etc., can solve problems such as reduction, and achieve the effects of reducing consumption, heat generation and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

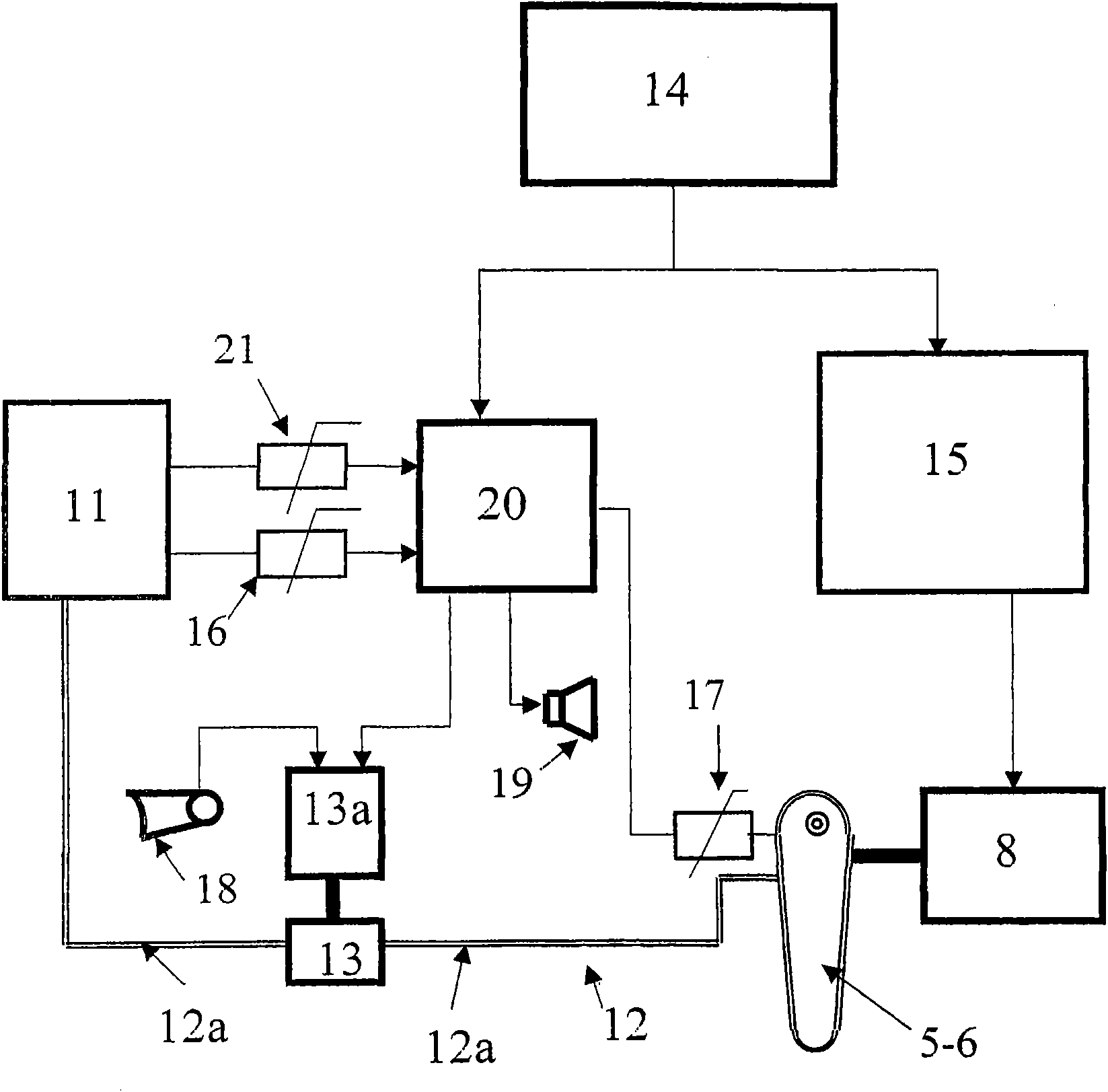

[0033] An advantageous but non-limitative example of the method of operation of the chainsaw and the lubrication system according to the invention is described below with reference to the accompanying drawings.

[0034] A chainsaw with a bar is described below, but it should be noted that the invention is also applicable to chainsaws with various handles (with simple handle, with raised handle, etc.).

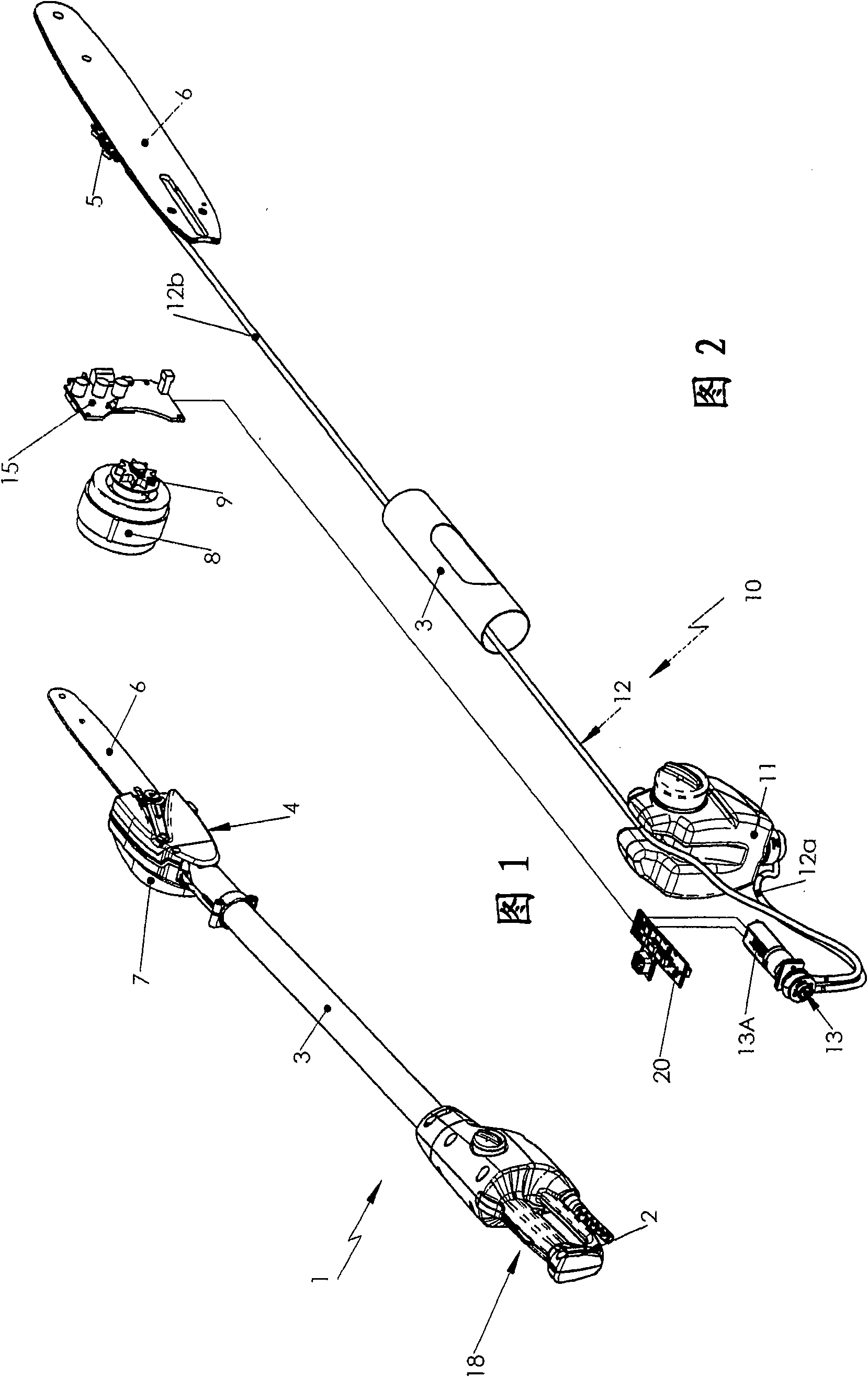

[0035] figure 1 Shown is a chainsaw 1 with a bar comprising a control handle 2 mounted at the lower end of a tubular bar 3 with a cutting head 4 rotatably mounted at its upper end.

[0036] The cutting head 4 comprises an endless cutting chain 5 mounted on the outer circumference of a drive pinion 9 and a chain guide 6 . The drive of the cutting chain 5 via the transmission pinion 9 is realized by an electric motor, which at figure 1 contained in the housing 7 and in the image 3 Indicated by reference numeral 8 . It is also not excluded that the drive is realized by means...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com