Method for manufacturing loach powder

A production method and loach technology, which are applied in the directions of food preparation, application, food science, etc., can solve the problems of fishy loach soup, unable to completely remove the oil content of loach, unpalatable, etc., and achieve the effect of convenient cooking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention capable of achieving the above objects will be described below with reference to the accompanying drawings.

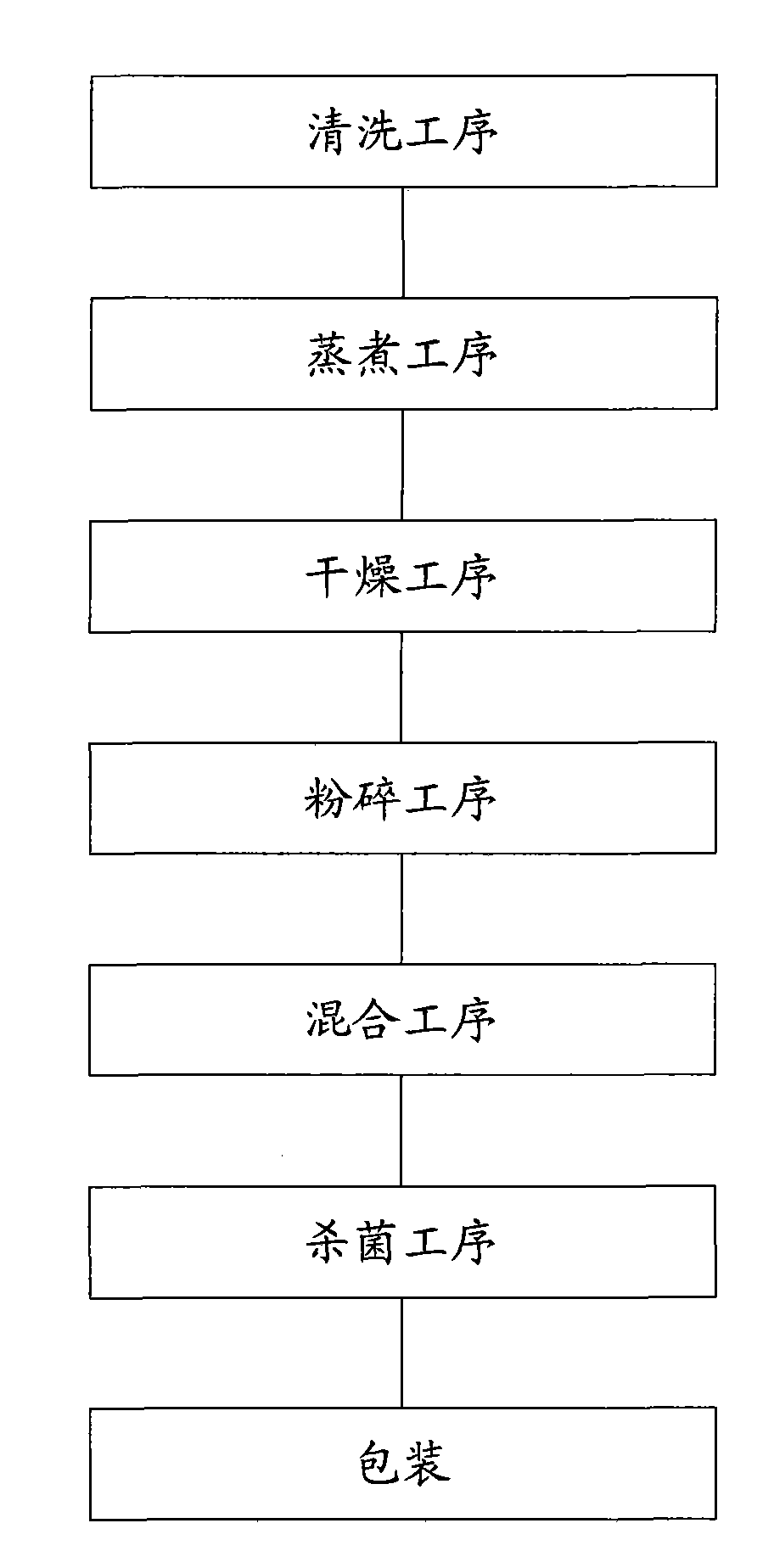

[0022] figure 1 It is a process block diagram showing the manufacturing process of loach powder applicable to the technology of the present invention.

[0023] The preparation method of the loach powder of the present invention comprises a cleaning process, a steaming process, a drying process, a crushing process, a mixing process and a sterilization process.

[0024] The cleaning process is to sprinkle salt on the loach and leave it for 3 hours, then wash with clean water to remove the salt, the foreign matter discharged from the loach and the foreign matter on the surface of the loach.

[0025] The cooking process is to place the cleaned loach on the dividing plate of the steamer and cook for 1 hour, so that the oil contained in the loach is discharged below the dividing plate.

[0026] The drying process is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com