Vertical type full automatic pressure filter

A fully automatic, filter press technology, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve problems such as difficult operation and maintenance, and achieve the effect of obvious energy saving, cost reduction, and uniform compression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

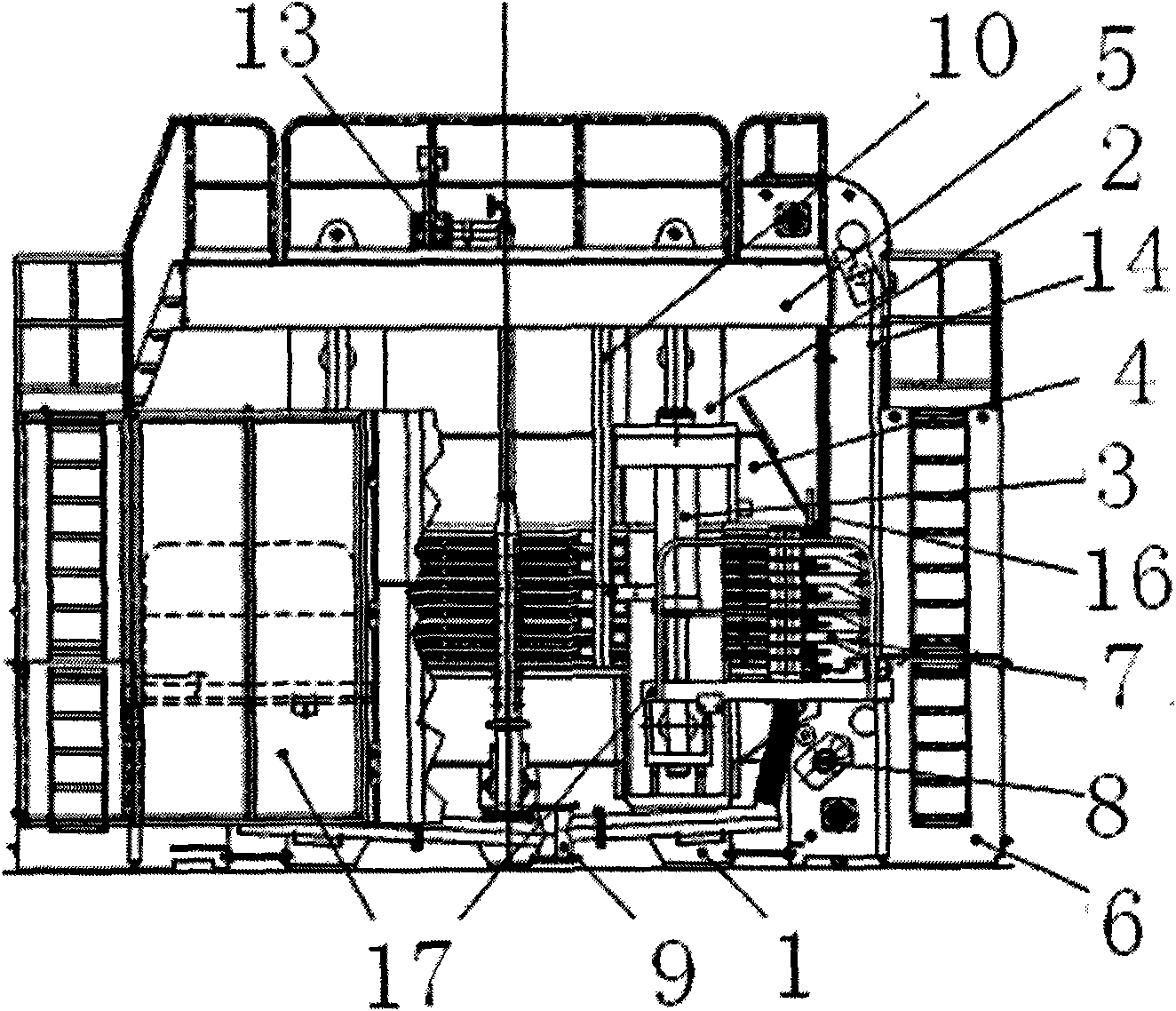

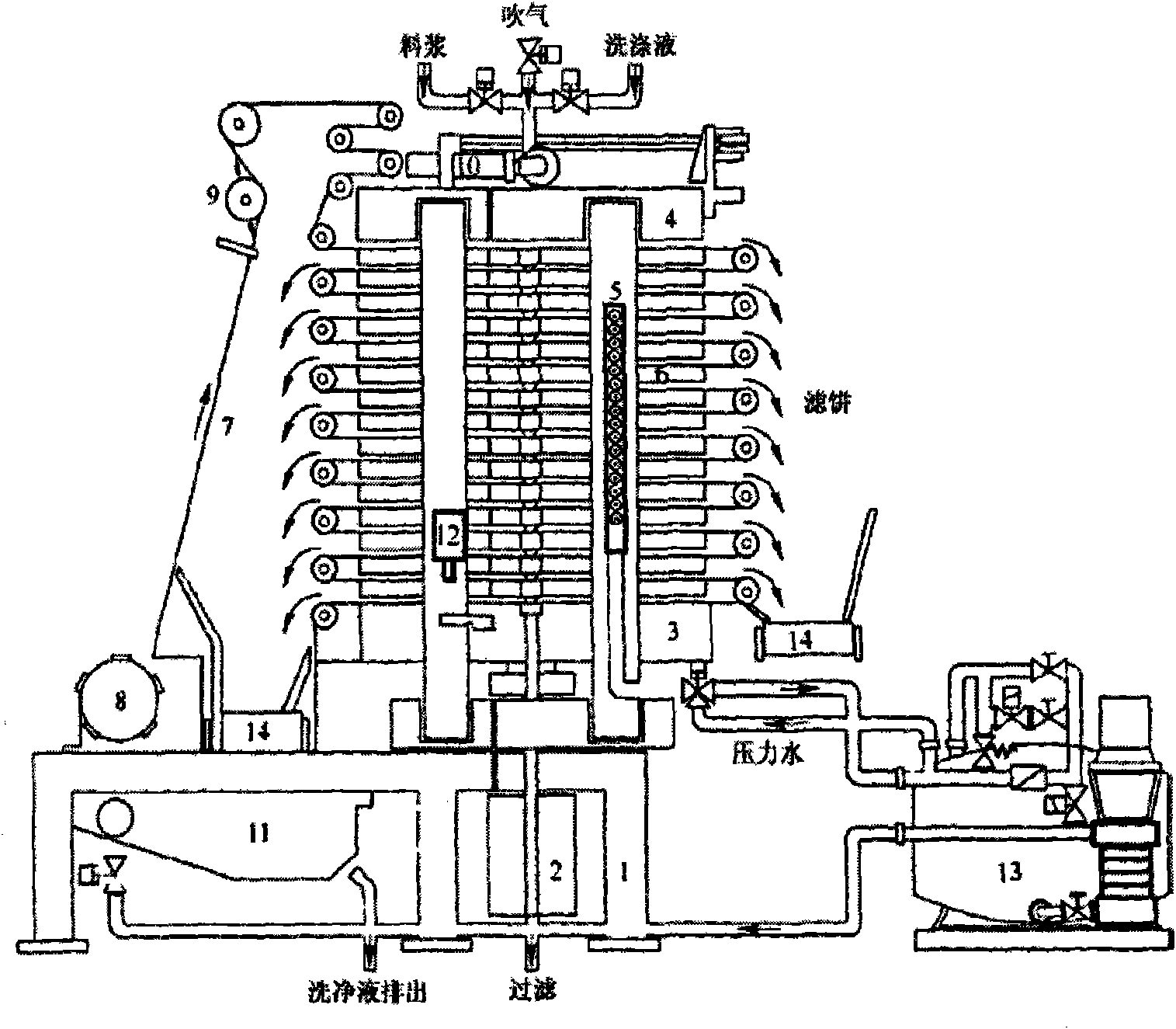

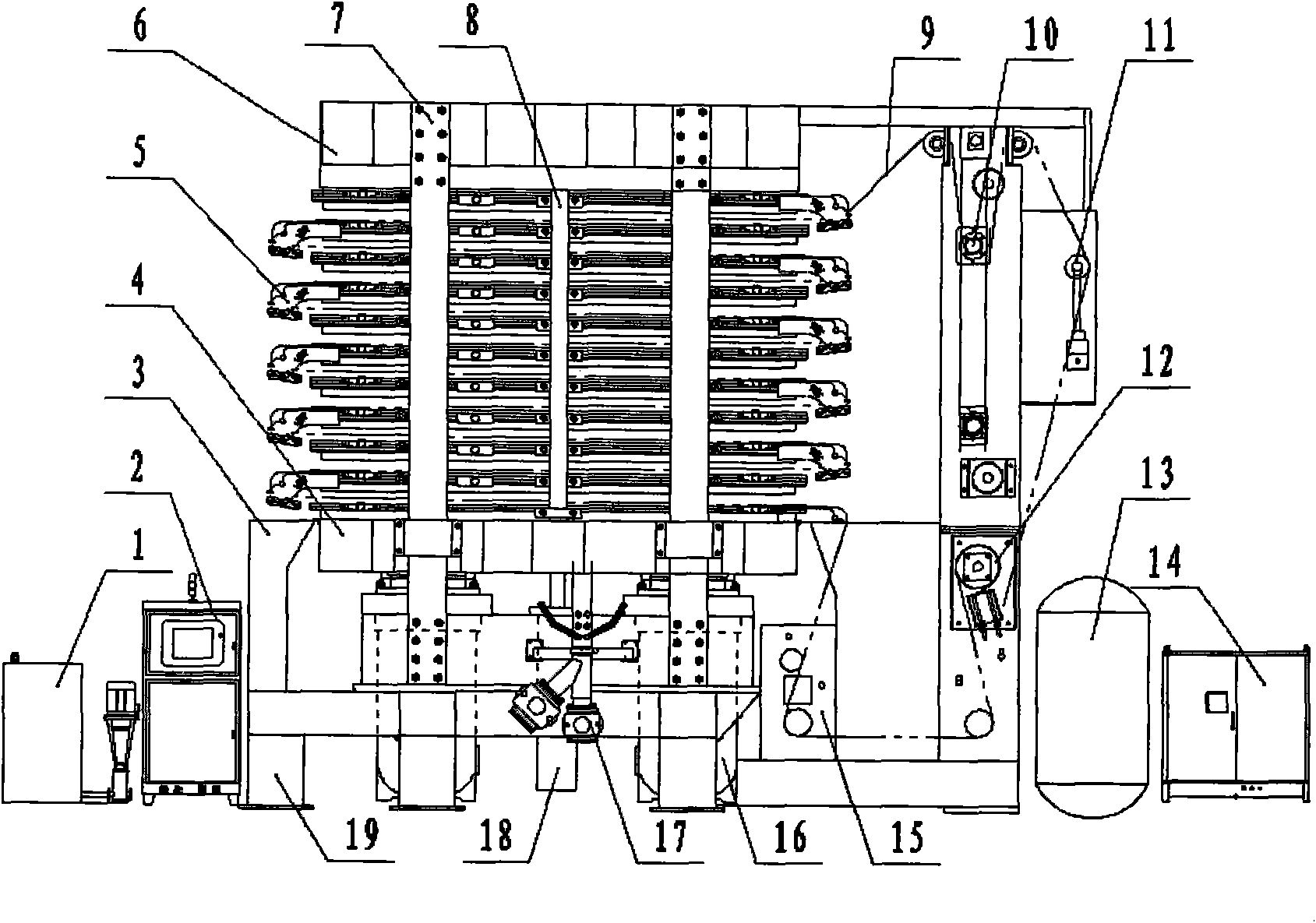

[0021] Vertical fully automatic filter press, two jacking cylinders 16 and one fast cylinder 18 are fixed on the frame 19, the lower pressing plate 4 is fixed on the jacking cylinder 16 and the quick oil cylinder 18, and the filter plate group 5 is placed on the lower pressing plate 4 , the filter plate group 5 is stacked, the upper platen 6 is fixed on the filter plate group 5 through the side plate 7, the guide column 8 guides the filter plate group 5, the filter cloth 9 is wound in S shape in the filter plate group 5, and the filter cloth 9 is in the The filter plate group 5 passes through the tensioning device 10, the deviation correction device 11, the driving device 12, the cleaning device 15, etc. to form a closed ring; the tensioning device 10 is fixed on the side frame of the equipment, and the deviation correction device 11 is fixed on the side of the equipment On the frame, the driving device 12 is under the side frame, the cleaning device 15 is fixed under the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com