Mixer and mixing plant or building and operation method of mixing plant or building

A technology of mixers and mixing plants, which is applied in mixing plants, cement mixing devices, clay mixing devices, etc., can solve the problems of not being able to meet market requirements and the low utilization rate of concrete mixing plants, so as to ensure high-efficiency production capacity and utilization rate, meet The effect of production demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

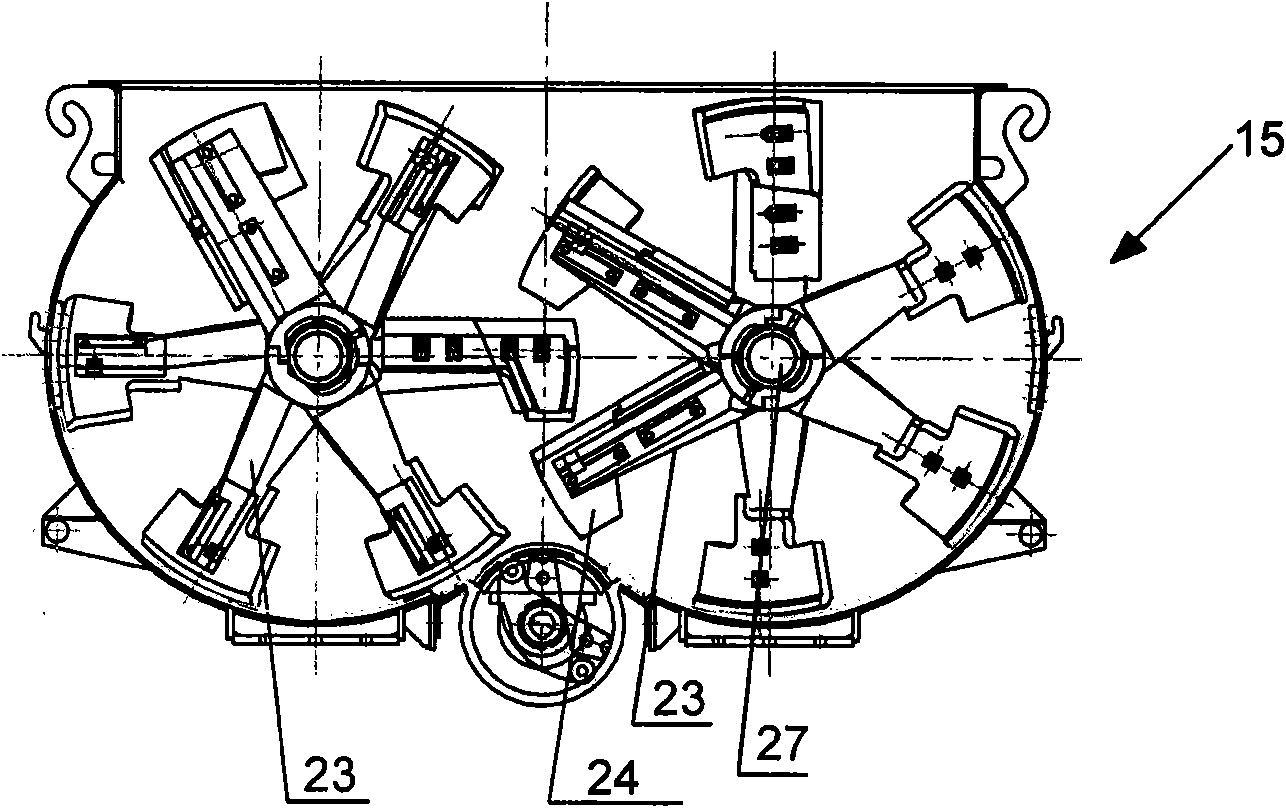

[0034] figure 1 A schematic diagram of the mixer 15 according to the present invention is shown in the first production mode, which is the concrete production mode. At this time, a first stirring arm 23 with a first stirring blade 24 is provided, and the first stirring arm 23 is connected to a stirring shaft 27 . The mixer 15 according to the invention is characterized in that both the first mixing arm 23 and the first mixing blade 24 can be replaced.

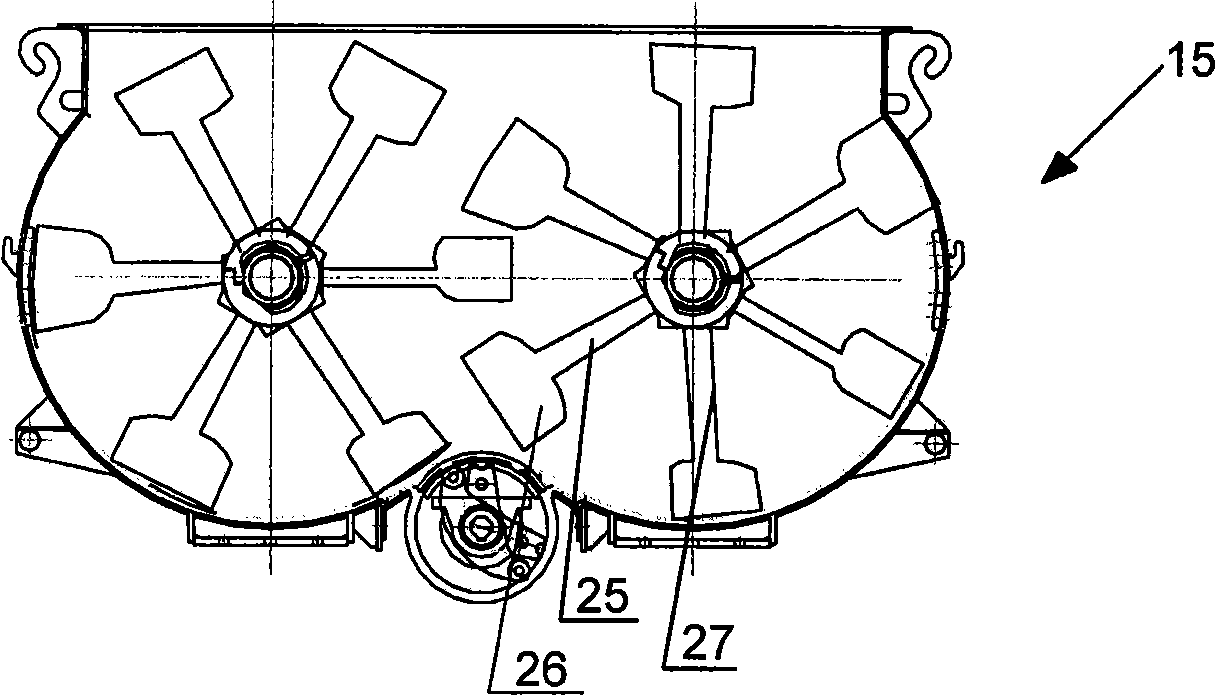

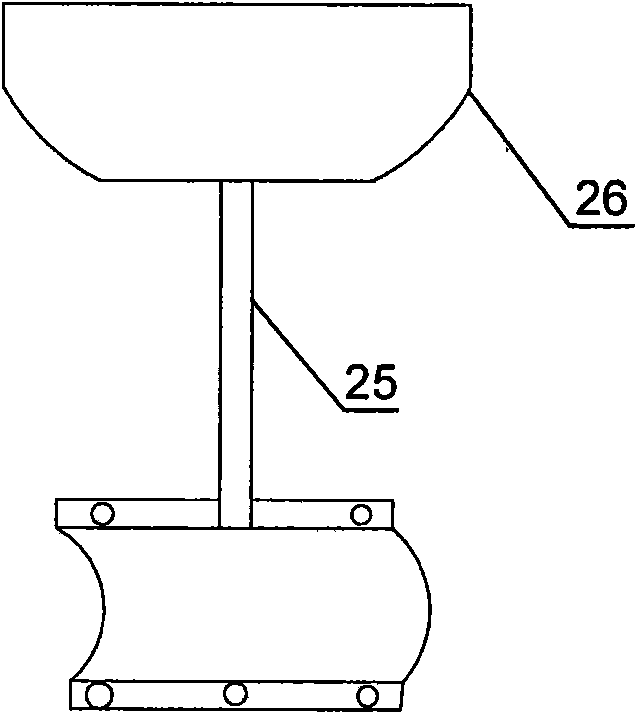

[0035] figure 2 A schematic diagram of a mixer according to the invention in a second production mode is shown. The second production mode is a dry-mixed mortar production mode, and the first agitating arm 23 and the first agitating blade 24 are replaced with the second agitating arm 25 and the second agitating blade 26 for producing dry-mixed mortar. The shape of the second stirring blade 26 can be paddle type or coulter type, image 3 A schematic structural view of the paddle-type second stirring arm 25 is shown.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com